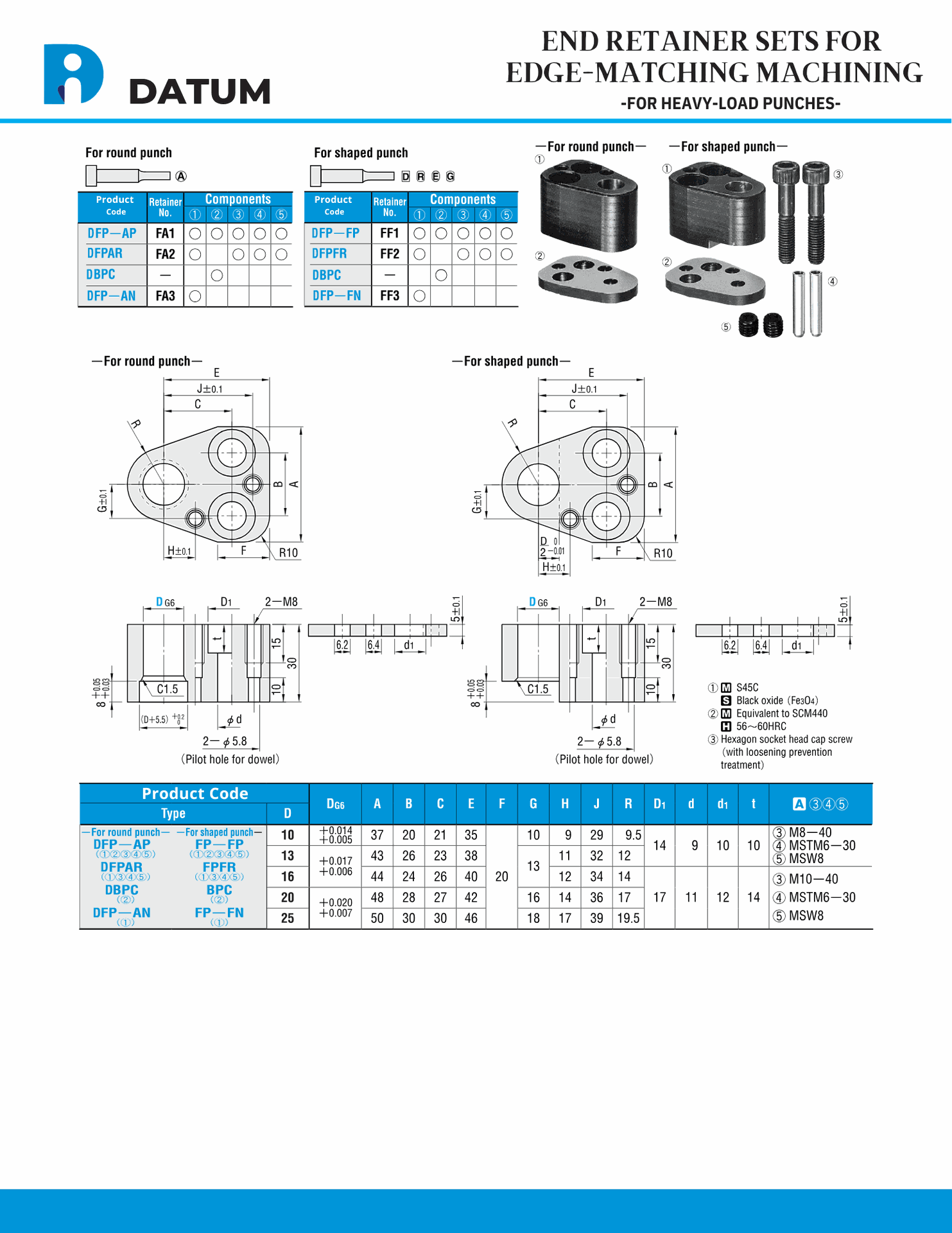

END RETAINER SETS FOR EDGE-MATCHING MACHINING

For Heavy Load Punches

End Retainer Sets for Edge-Matching Machining are designed to provide unmatched precision and stability for heavy load punches in press-in-die applications. These retainer sets ensure proper alignment and positioning during machining, enhancing operational efficiency and reducing wear. Engineered for high-stress environments, they are ideal for industries requiring durability and accuracy, such as automotive and aerospace. Built from robust materials, these sets distribute load evenly, maintaining punch integrity and boosting tool lifespan. Optimize machining performance with reliable, heavy-duty retainer solutions tailored for edge-matching tasks.

End Retainer Sets for Edge-Matching Machining are expertly crafted to deliver superior performance in maintaining the position of heavy load punches during press-in-die operations. These retainers are engineered to ensure precise alignment and secure placement, reducing the risk of misalignment and operational delays. Ideal for edge-matching machining applications, they provide enhanced stability and durability under high-stress conditions, making them a perfect choice for industries such as automotive, aerospace, and heavy machinery manufacturing.

Constructed from high-strength materials, these retainer sets are designed to withstand repeated use without compromising on quality or accuracy. They effectively distribute pressure evenly across the punch, minimizing wear and tear while extending the tool's lifespan. The robust design ensures reliability in maintaining exact positioning, even during demanding applications, enhancing productivity and reducing downtime.

End Retainer Sets for Heavy Load Punches are a vital component for achieving precision and consistency in machining tasks. By ensuring seamless integration with edge-matching processes, they contribute to improved operational efficiency and reduced maintenance requirements. Invest in these high-performance retainer sets to optimize your machining operations and achieve unparalleled accuracy and durability.