Manufacturing Divisions

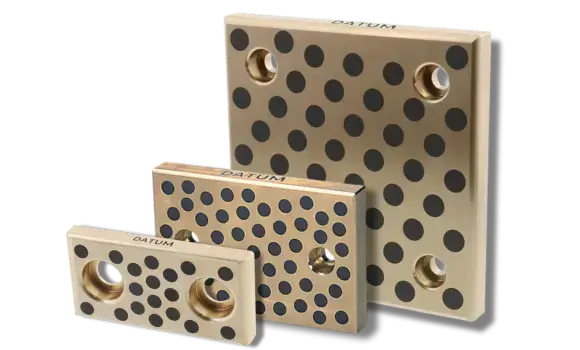

Datum Tools has different manufacturing divisions mainly in Pillar Sets, Punch Die Buttons, Lifting Hooks, Die Sets, Cushion Pins, Punch Retainers, Engraving Punches, Nest Guides, Lifting Bars, Spool Retainers, Wear Plates, Heel Guide Plates, Dowel Pins, etc. and many other Standard & Non-Standard precision components.

Ready Stocks Available For :

- Guide Post Set

- Punch

- Die Button

- Dowel Pin

- Ball Cage

- Die Set

- Cushion Pins

- Wear Plates

2024

• Achieved annual turnover of $20M

• 200+ workforce

• 150+ machines including multiple CNCs, VMCs etc

• Exports to 10+ countries.

Moved to a Bigger production unit having 100k sq.ft space

Started Exporting to other countries outside of India

Established Datum as a Private Limited Company - Datumtools Pvt. Ltd.

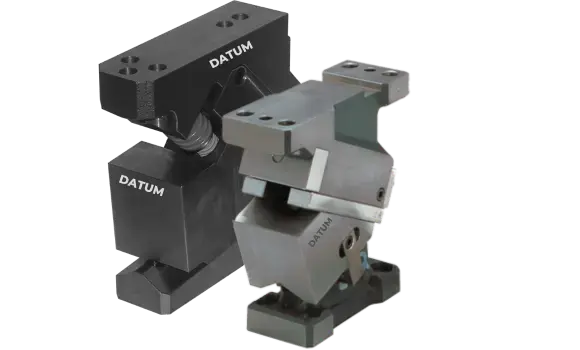

Introduced a range of CAM units

•Reached a milestone of $5M annual turnover

• 50+ Workforce

• 50+ Machinery - CNCs, VMCs, etc.

• Expanded Production Unit to 40,000 Sq Ft

• Introduced a wide variety of Oil-less components

• Bought first CNC machine

• Introduced various new items like Punches, Ball Cage, etc.

• Rebranded as Datum India

• Started Manufacturing of Standard Die Parts

• 10+ Workforce

• 10+ Manual Machinery - Lathe, Grinders, etc.

Founded in 1995 as Chander Engineers with one lathe in a 1500 sq. ft. unit.

Range of Products

Our comprehensive product line includes Cam Units, Guide Post Sets, Punches, Lifting Hooks, Dowel Pins, Retainers, Die Buttons, Pillar Sets, Ball Cages, Guide Bush, Die Springs, Gas Springs, and much more.