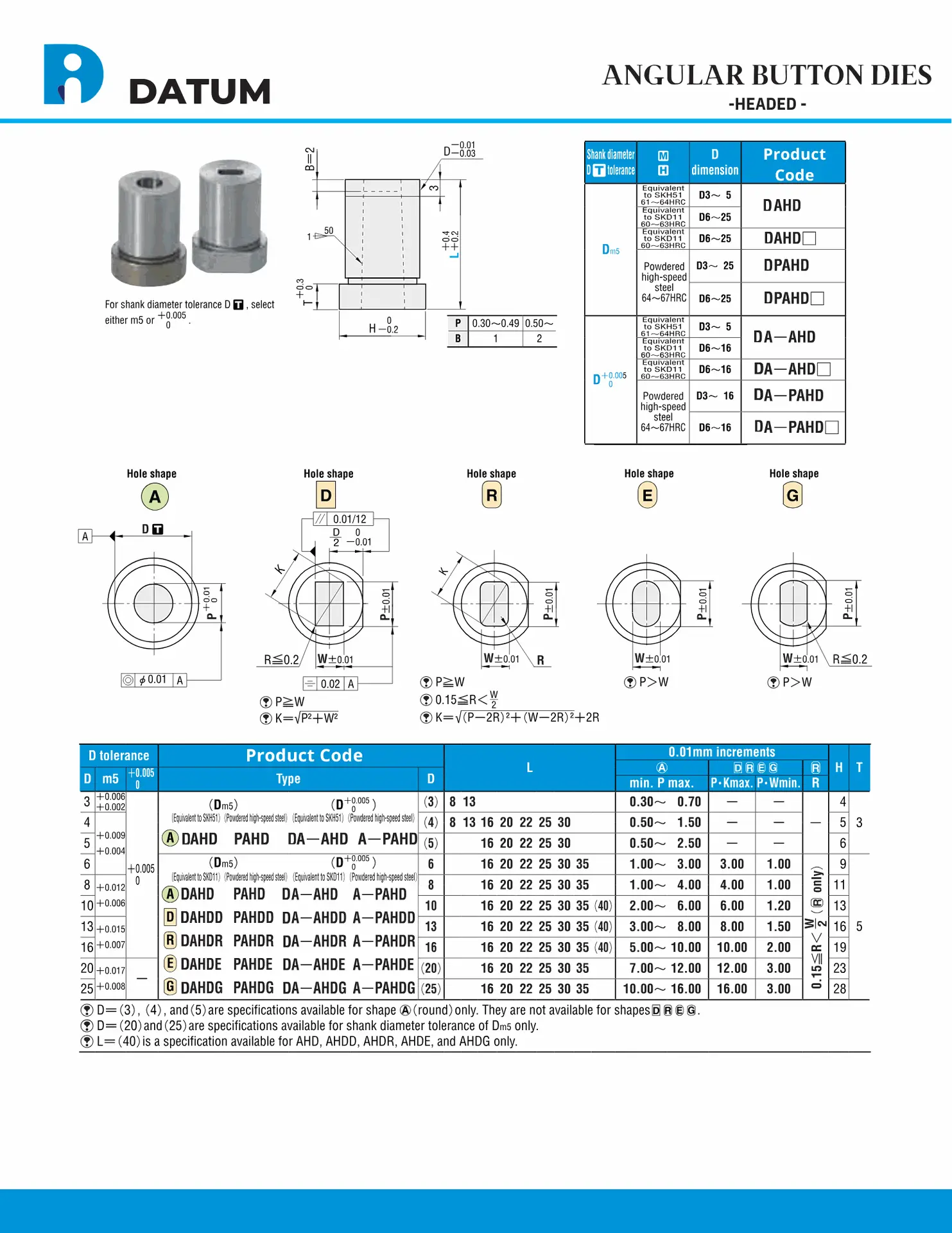

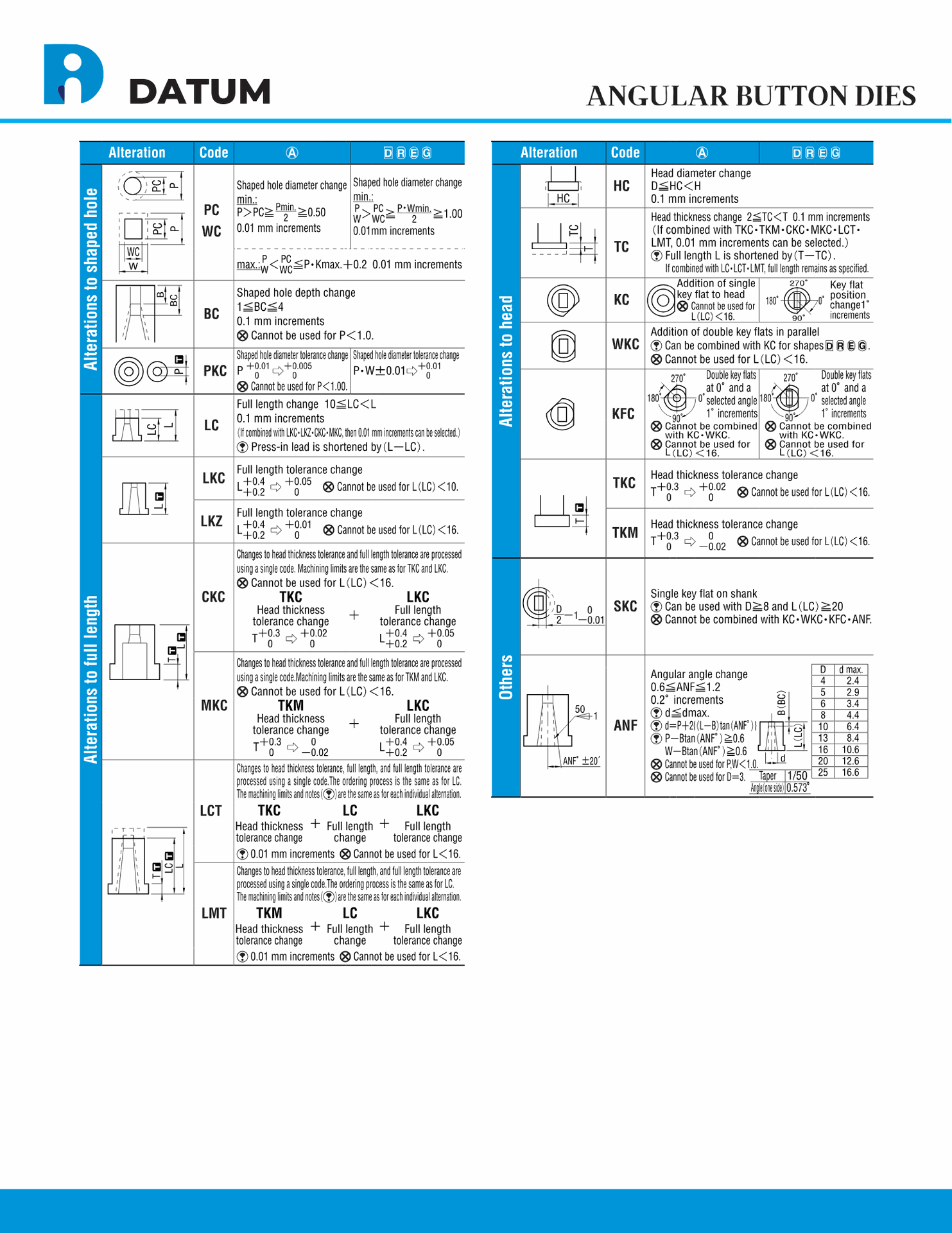

ANGULAR BUTTON DIES

(Headed)

Angular button dies (headed) are essential for precision and stability in maintain position press dies. The headed design enhances alignment and durability, ensuring consistent performance during high-speed and high-pressure stamping operations. These dies are engineered to efficiently handle angular cuts, providing superior accuracy and reducing material waste. Ideal for industries like automotive and electronics, they improve production efficiency and tool life. Angular button dies with a headed configuration deliver reliable results, optimizing the metal stamping process and ensuring consistent, high-quality output.

Angular button dies (headed) are vital components in maintain position press dies, offering enhanced precision, stability, and durability for metal stamping applications. Designed with a headed configuration, these dies provide superior alignment and support, ensuring consistent and reliable performance even in high-speed and high-pressure operations.

The unique angular design makes these button dies ideal for applications requiring precise angular cuts or punches. The headed feature further enhances tool stability, reducing the risk of misalignment and minimizing material waste. Industries such as automotive, aerospace, and electronics benefit significantly from these dies due to their ability to deliver high-quality, accurate results in demanding production environments.

Manufactured from robust materials, headed angular button dies are engineered for extended tool life, resisting wear and deformation even under continuous use. Their efficient scrap retention capabilities help maintain a clean and streamlined stamping process, reducing downtime and optimizing workflow efficiency.

Investing in angular button dies with a headed design is a practical choice for manufacturers seeking to improve production precision, reduce waste, and ensure consistent output. These dies combine efficiency, reliability, and cost-effectiveness, making them an indispensable part of modern metal stamping operations.