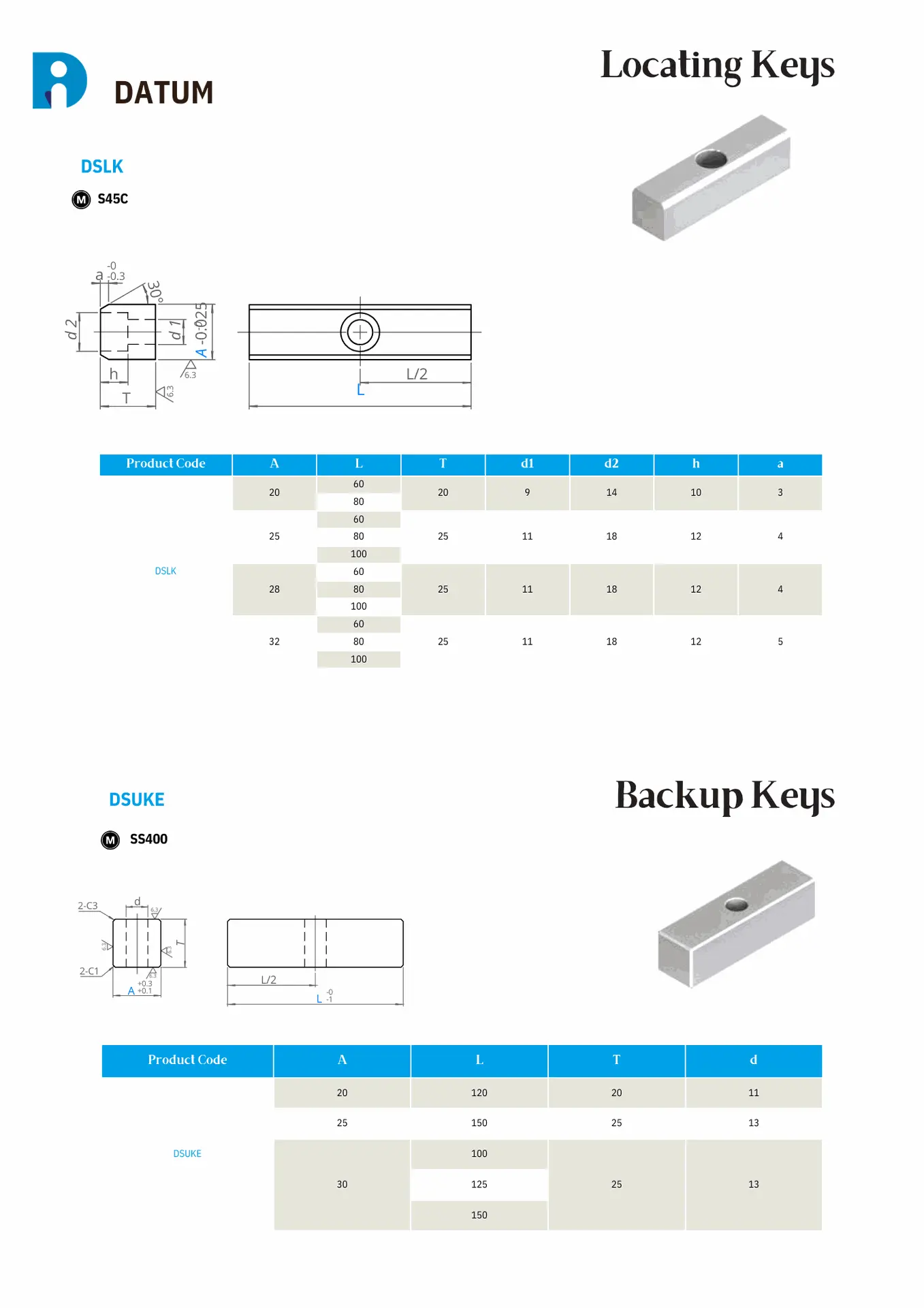

Backup Keys-DSUKE

Maximize die precision and longevity with high-quality backup keys designed to maintain stable positioning in press dies. These essential components provide even pressure distribution, reducing wear, minimizing misalignment, and preventing costly downtime. Built to withstand demanding environments, backup keys are ideal for automotive, metalworking, and manufacturing industries that rely on consistent die performance. By securing the die in place, these keys enhance alignment, improve operational efficiency, and extend equipment life.

Backup keys are essential components used in press dies to maintain the precise position and alignment of the die during operation. They play a crucial role in stabilizing the die by ensuring even pressure distribution, which reduces wear and helps prevent misalignment over time. This stability is vital in high-stress manufacturing environments, such as automotive and metalworking, where precision and durability are necessary to achieve consistent results. By securely holding the die in place, backup keys contribute to extended die life, reduced maintenance, and minimized downtime, improving overall production efficiency.

Why are Backup Keys Important?

- Maintains Die Alignment: Backup keys ensure that the die remains aligned throughout the pressing process, preventing any shifting that could lead to inaccuracies in part production.

- Reduces Wear and Tear: By securing the die, backup keys evenly distribute pressure and reduce the strain on die components. This helps in extending the life of both the die and the press machine.

- Minimizes Downtime: Misalignment in dies can lead to machine jams or defective parts, requiring time-consuming adjustments. Backup keys reduce these issues, minimizing downtime and increasing production efficiency.

- Improves Quality and Consistency: With backup keys maintaining proper alignment, parts produced are more likely to meet precise specifications, enhancing quality and reducing rejection rates.