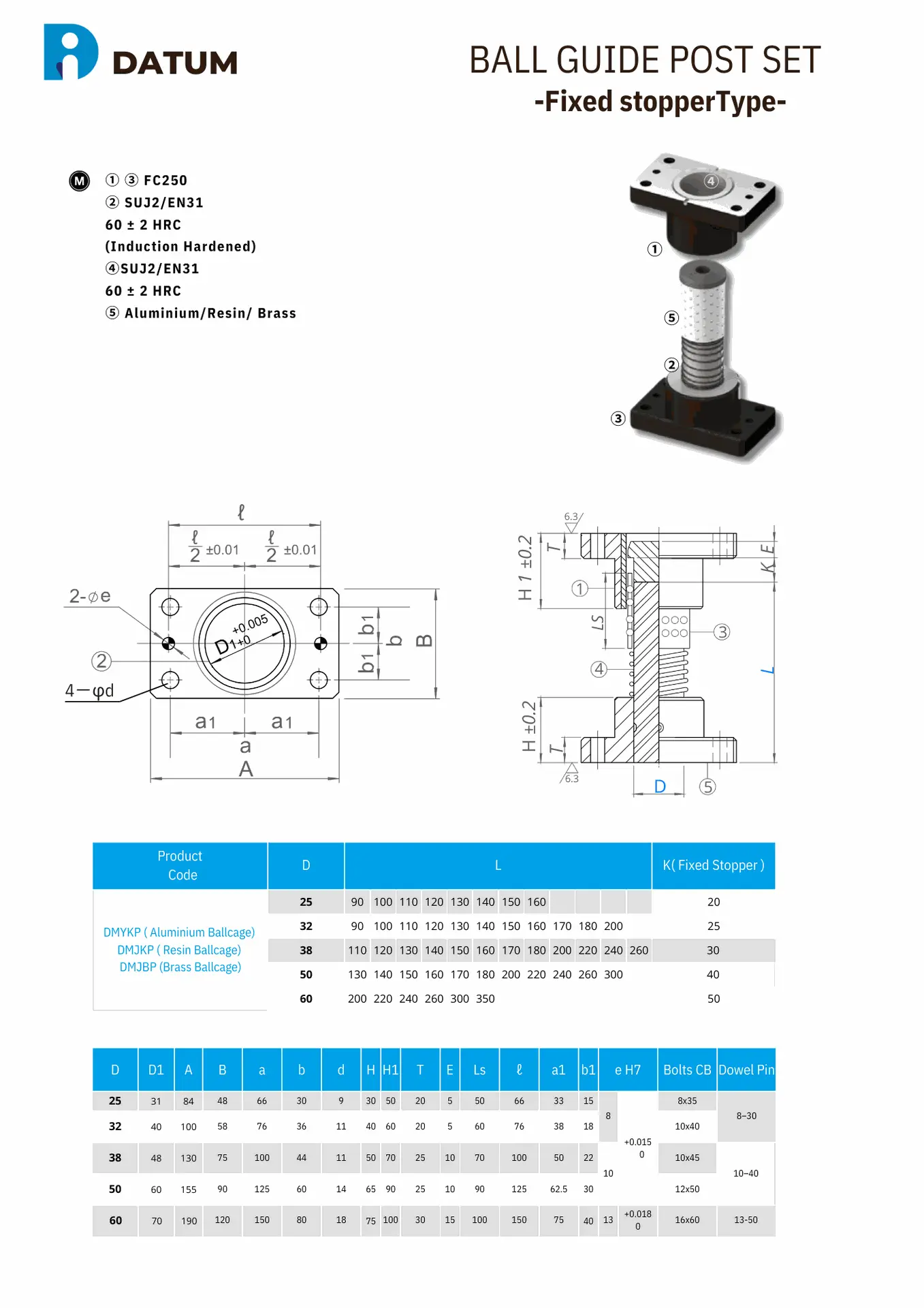

Ball Guide post set-Fixed stopperType DMJBP (Brass Ballcage)

Enhance your die maintenance with the Ball Guide Post Set - Fixed Stopper Type DMJBP, featuring a robust brass ballcage design. This high-quality component is specifically engineered to maintain precise positioning in press operations, ensuring stability and alignment throughout the manufacturing process.The fixed stopper design offers reliable support, preventing unwanted movement and minimizing wear on both the die and press. Constructed from durable materials, the DMJBP set is built to withstand the rigors of industrial environments, making it an ideal choice for manufacturers seeking longevity and efficiency.

The Ball Guide Post Set - Fixed Stopper Type DMJBP features a durable brass ballcage design, specifically engineered for maintaining precise positioning during press operations. This essential component is vital for ensuring that dies remain stable and aligned throughout the manufacturing process, promoting high-quality production results.

Why Use the DMJBP Ball Guide Post Set in Die Maintenance?

- Precision Positioning: The primary purpose of the DMJBP Ball Guide Post is to maintain the correct alignment of dies during pressing. This precision is crucial for reducing production errors and ensuring consistent quality in the final products.

- Durable Brass Construction: Crafted from high-quality brass, the ballcage is designed to withstand the demanding conditions of industrial environments. Its robust construction minimizes wear and tear, extending the lifespan of both the guide post and the die.

- Fixed Stopper Design: The fixed stopper feature provides reliable support, preventing unwanted movement during operation. This stability is essential for maintaining the integrity of the manufacturing process and reducing defects.