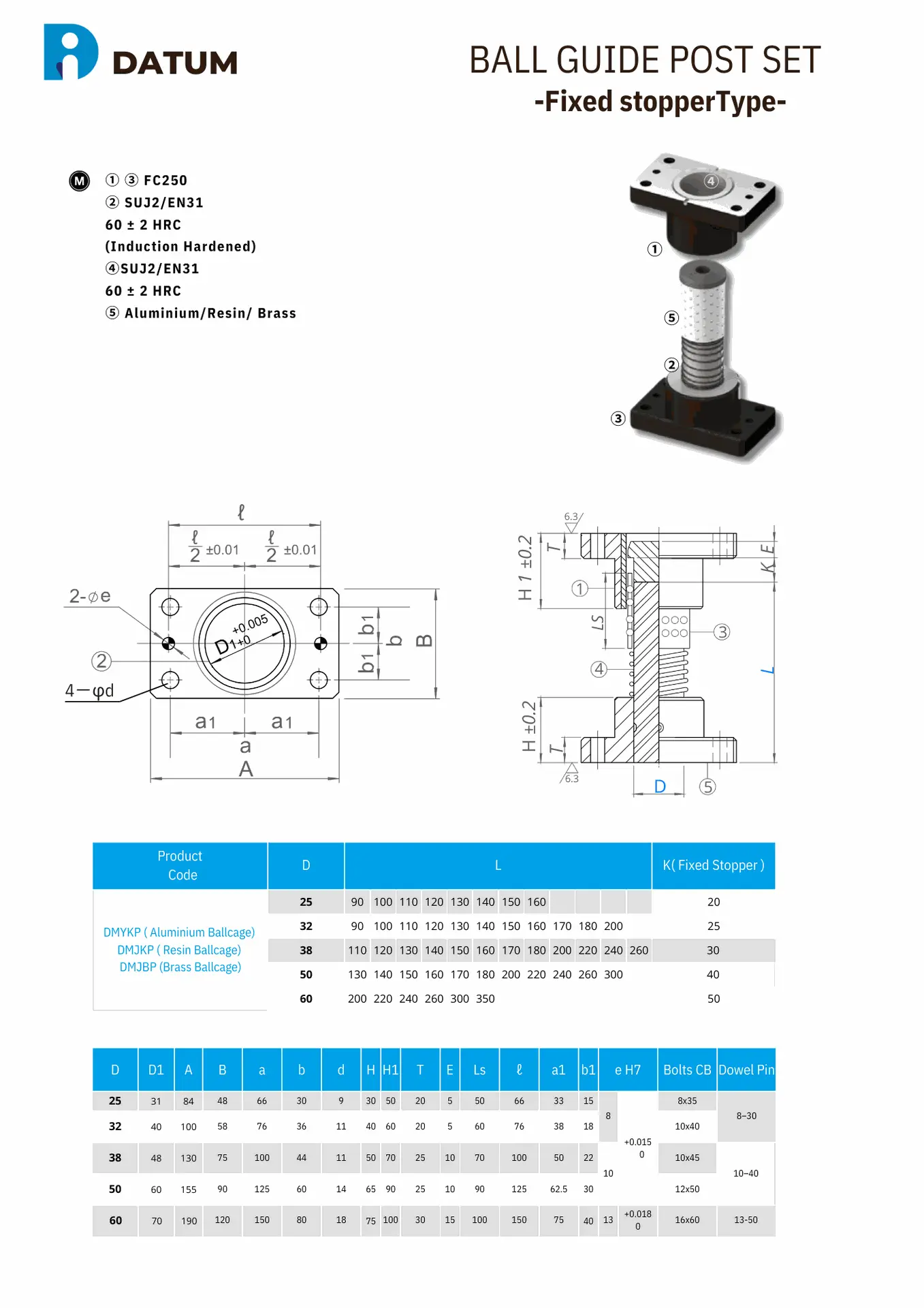

Ball Guide post set-Fixed stopperType - DMJKP ( Resin Ballcage)

Optimize your die maintenance with the Ball Guide Post Set - Fixed Stopper Type DMJKP, featuring a high-quality resin ballcage design. Engineered to ensure precise positioning during press operations, this essential component provides exceptional stability and alignment for your dies. Experience improved production accuracy and reduced downtime with the DMJKP Ball Guide Post Set. Its easy installation and compatibility with various die setups make it a versatile addition to your manufacturing toolkit. Elevate your operational efficiency and achieve consistent results with this indispensable component.

A Ball Guide Post Set is an essential component used to guide and align moving parts in various machining applications. The Fixed Stopper Type is specifically designed to maintain the correct positioning of components during die pressing, ensuring optimal performance and reducing the risk of errors.

Key Features

- Fixed Stopper Mechanism:

- The fixed stopper prevents any unintended movement of the workpiece, ensuring consistent and precise alignment during the pressing process.

- Durable Resin Ballcage:

- Made from high-quality resin, the ballcage provides smooth operation with reduced friction. This results in less wear and longer service life compared to traditional metal options.

- Ease of Installation:

- Designed for quick and straightforward installation, this ball guide post set minimizes downtime and allows for rapid integration into existing systems.

- Versatile Usage:

- Ideal for a range of applications across industries, including automotive, aerospace, and manufacturing, where precision and reliability are paramount.

Benefits of Using the Fixed Stopper Type with Resin Ballcage

- Enhanced Accuracy: The combination of a fixed stopper and resin ballcage ensures that components remain in precise alignment, which is essential for high-tolerance applications.

- Improved Efficiency: Lower friction translates to less energy consumption and reduced wear, leading to cost savings and enhanced operational efficiency.

- Reliability: The robust design of the fixed stopper and resin material ensures consistent performance even under demanding conditions, minimizing the risk of failure.

- Maintenance-Free Operation: The resin ballcage requires little to no lubrication, which reduces maintenance efforts and increases productivity.

The Fixed Stopper Type with Resin Ballcage is perfect for:

- Die Casting: Maintains accurate die alignment, enhancing the quality of cast parts.

- Metal Forming: Ensures stability during pressing operations, leading to better end-product consistency.

- Production Lines: Facilitates precise positioning of components, improving overall assembly efficiency.