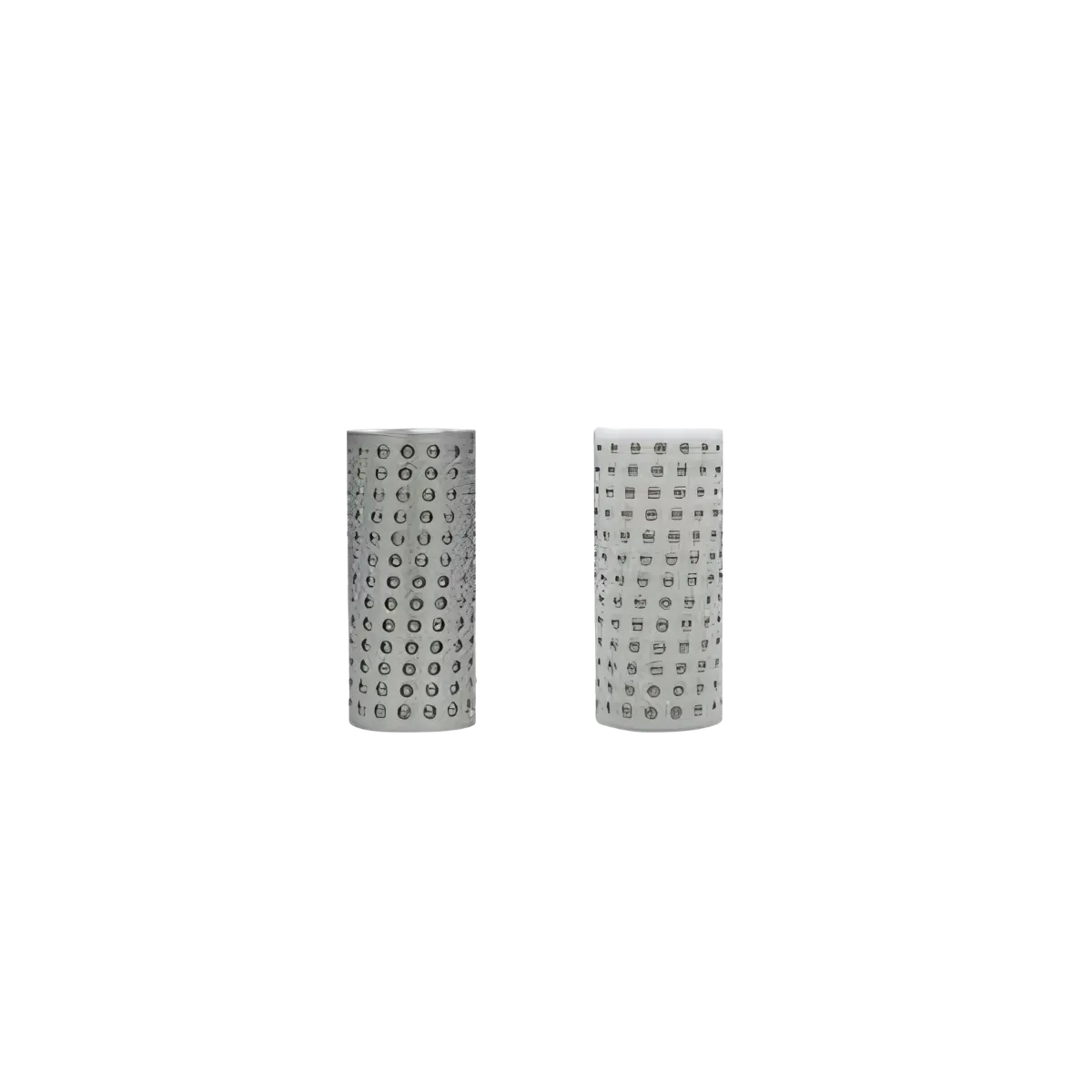

The Ball Retainers - DSB-A (Aluminum) are designed to maintain precise positioning in die press applications, ensuring accurate alignment and stability throughout high-stress manufacturing processes. Made from lightweight yet durable aluminum, these ball retainers offer excellent wear resistance and longevity, making them ideal for high-demand environments. With their ability to support smooth, low-friction movement, they enhance the efficiency and lifespan of die components. Perfect for use in progressive and transfer dies, the DSB-A Ball Retainers improve productivity, reduce maintenance needs, and ensure consistent, high-tolerance results in every press cycle.

Ball Retainers -DSB-A (Aluminum)

In die press applications, Aluminum Ball Retainers play a critical role in maintaining precise positioning and ensuring stable alignment of components, which is essential for high-quality, repeatable production. These retainers are made from premium-grade aluminum, combining lightweight properties with exceptional durability to withstand the wear and tear of continuous press operations. Their lightweight design reduces overall system load, while the inherent strength of aluminum ensures a long-lasting solution that resists deformation and wear, even under heavy-duty usage.

One of the key advantages of using aluminum ball retainers is their ability to deliver smooth, low-friction movement, which optimizes the functionality of press components. This low-friction quality not only improves the efficiency of the die system but also reduces the wear on both the retainers and surrounding components. By minimizing friction, aluminum ball retainers contribute to less maintenance downtime, allowing for consistent, high-tolerance production in demanding settings such as progressive and transfer die systems.

Aluminum ball retainers are ideal for manufacturers aiming to enhance their press performance while reducing maintenance needs. Their precise alignment capabilities ensure each press cycle achieves optimal accuracy, minimizing the potential for misalignment and component shift that can affect product quality. The longevity of these retainers also translates into cost savings over time, as they require less frequent replacement compared to other materials.

Integrating aluminum ball retainers into a die setup not only maximizes productivity but also supports sustainability goals by extending the lifespan of equipment. For manufacturers focused on producing consistent, high-tolerance results with every press, aluminum ball retainers offer a balanced solution that combines durability, efficiency, and precision. Their role in improving operational performance makes them an invaluable component in modern, high-output production lines, where reliable performance is paramount.