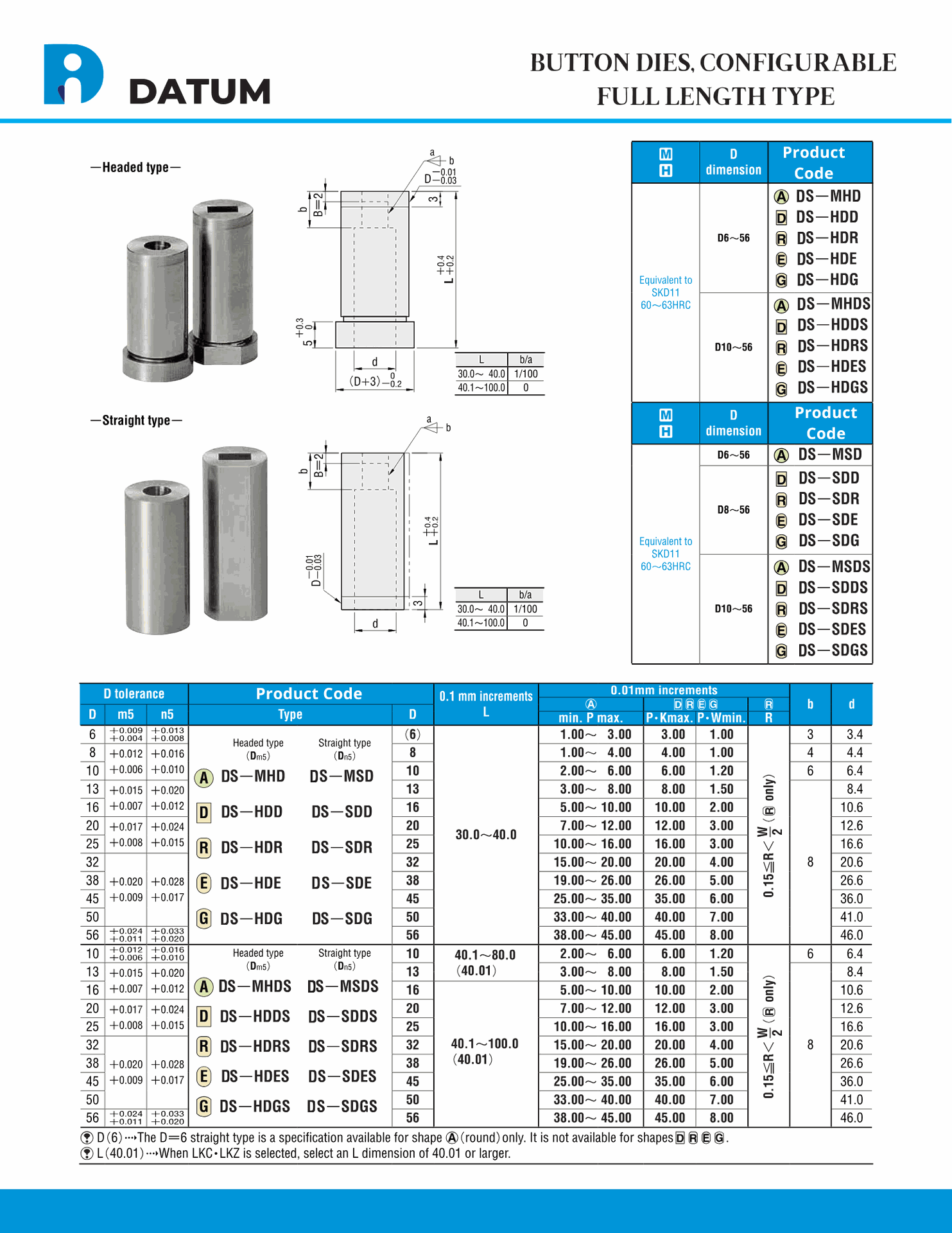

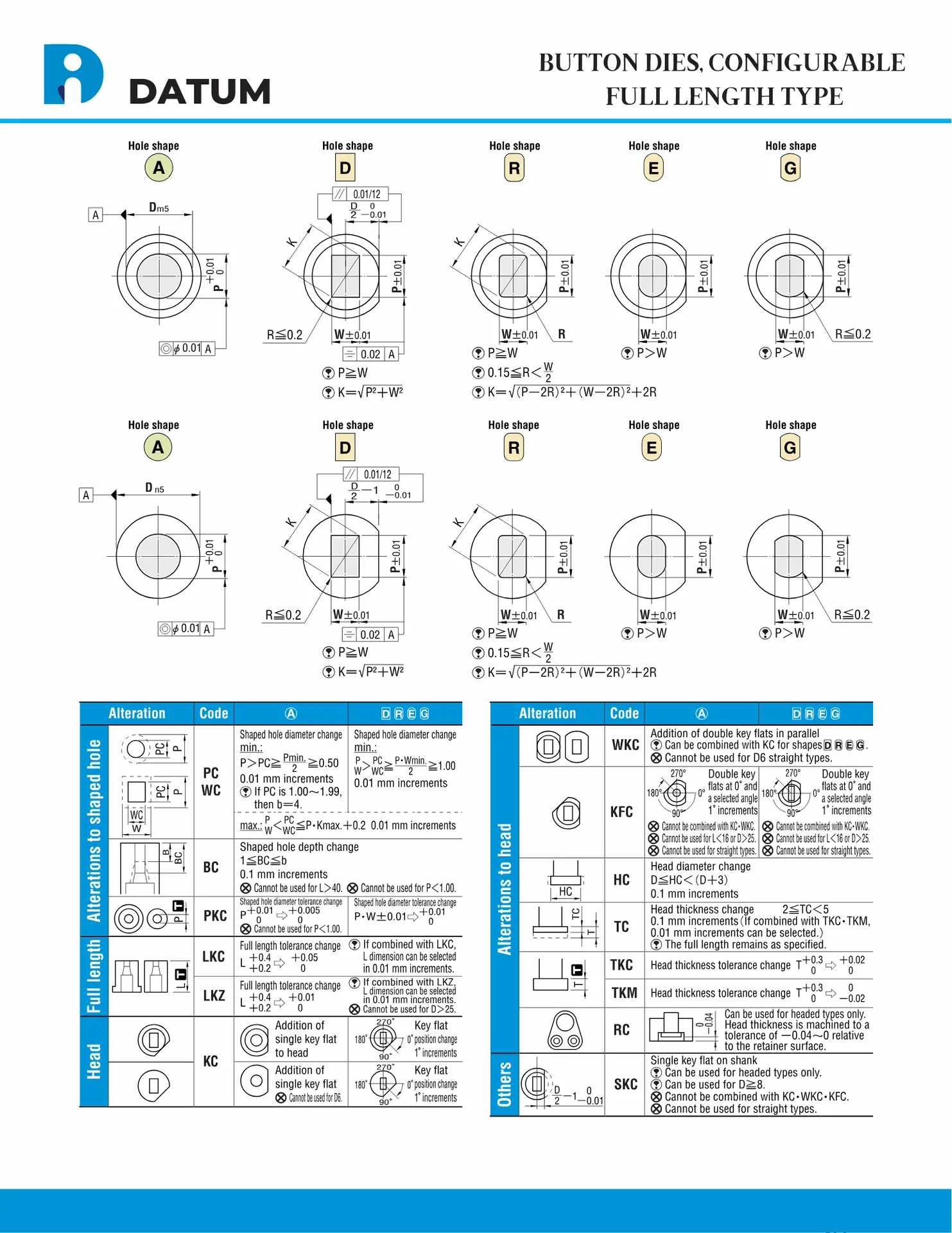

BUTTON DIES, CONFIGURABLE

FULL LENGTH TYPE

Configurable full-length button dies are designed for maximum flexibility and precision in maintain position press dies. These versatile dies can be easily adjusted to suit a wide range of stamping applications, providing accurate and consistent results. Ideal for high-speed metal forming processes, these dies ensure efficient scrap retention and clean punching. Built from durable materials, they offer long-lasting performance, reducing maintenance and downtime. Perfect for industries like automotive, aerospace, and electronics, configurable full-length button dies enhance productivity and ensure high-quality output.

Configurable full-length button dies are an ideal solution for manufacturers seeking precision, flexibility, and efficiency in maintain position press dies. These versatile dies are designed to handle a wide range of stamping applications, allowing easy adjustment to accommodate different production needs. Their adaptability ensures accurate and consistent performance across various industries, including automotive, aerospace, and electronics.

The full-length configuration of these button dies provides enhanced stability during high-speed, high-pressure operations. With efficient scrap retention capabilities, these dies help maintain a clean production environment, minimizing waste and improving overall workflow. Their customizable design also reduces downtime, allowing manufacturers to quickly switch between different die setups, further optimizing production efficiency.

Made from high-quality, durable materials, configurable full-length button dies offer excellent tool life and reduced wear, making them a cost-effective investment in long-term production operations. These dies deliver superior performance, minimizing the need for frequent replacements and ensuring high-quality output with every cycle.

For manufacturers looking to optimize their stamping processes, increase productivity, and reduce operational costs, configurable full-length button dies are the ideal solution. Their flexibility, durability, and precision make them a valuable asset for any high-volume metal forming operation.