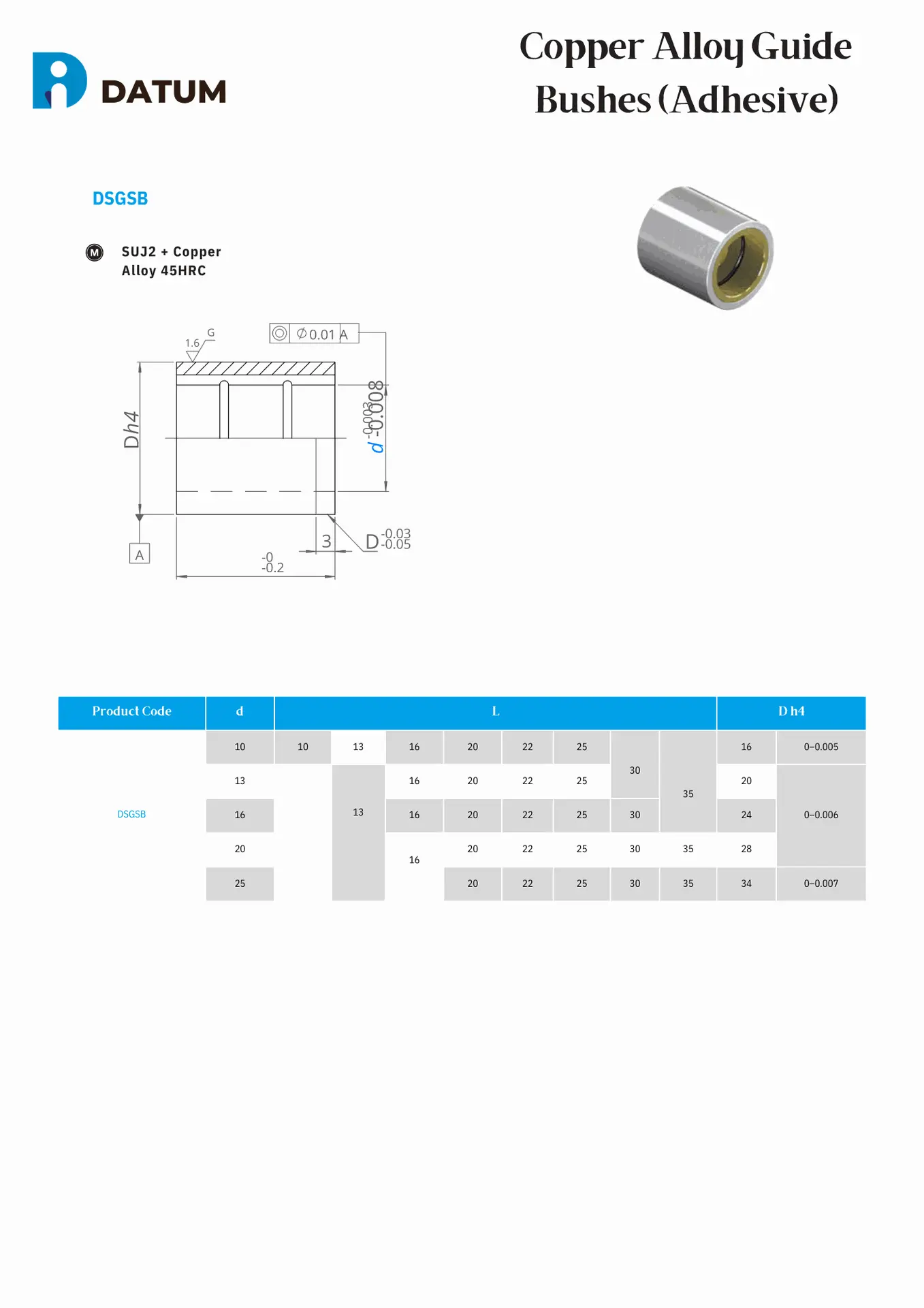

Copper Alloy Guide Bushes (Adhesive)-

DSGSB

The Copper Alloy Guide Bushes (Adhesive) - DSGSB are designed to provide exceptional support and precise alignment in die applications, ensuring stability during pressing operations. These high-quality guide bushes are made from durable copper alloy, enhancing wear resistance and longevity. The adhesive feature ensures a secure bond within the die, minimizing movement and maintaining consistent positioning throughout the production process. Ideal for progressive and transfer dies, DSGSB guide bushes optimize operational efficiency, reduce maintenance needs, and deliver reliable, high-tolerance results, making them essential for high-quality manufacturing environments.

The Copper Alloy Guide Bushes (Adhesive) - DSGSB are engineered to deliver reliable support and precise alignment in die applications, making them an essential component for maintaining stability during pressing operations. Crafted from high-quality copper alloy, these guide bushes offer exceptional wear resistance and longevity, ensuring optimal performance even under demanding conditions.

The unique adhesive feature allows for a secure bond within the die, significantly minimizing movement and ensuring consistent positioning throughout the production process. This stability is crucial for achieving high-tolerance results, particularly in progressive and transfer die applications where precision is paramount.

Designed to optimize operational efficiency, the DSGSB guide bushes help reduce maintenance needs and extend the lifespan of die components, ultimately contributing to lower production costs and increased productivity. By providing reliable alignment and support, these guide bushes play a key role in enhancing overall manufacturing quality.

For manufacturers seeking a dependable solution for die positioning, the Copper Alloy Guide Bushes (Adhesive) - DSGSB offer the perfect combination of durability, precision, and efficiency, ensuring that high-quality output is consistently achieved in even the most demanding manufacturing environments.