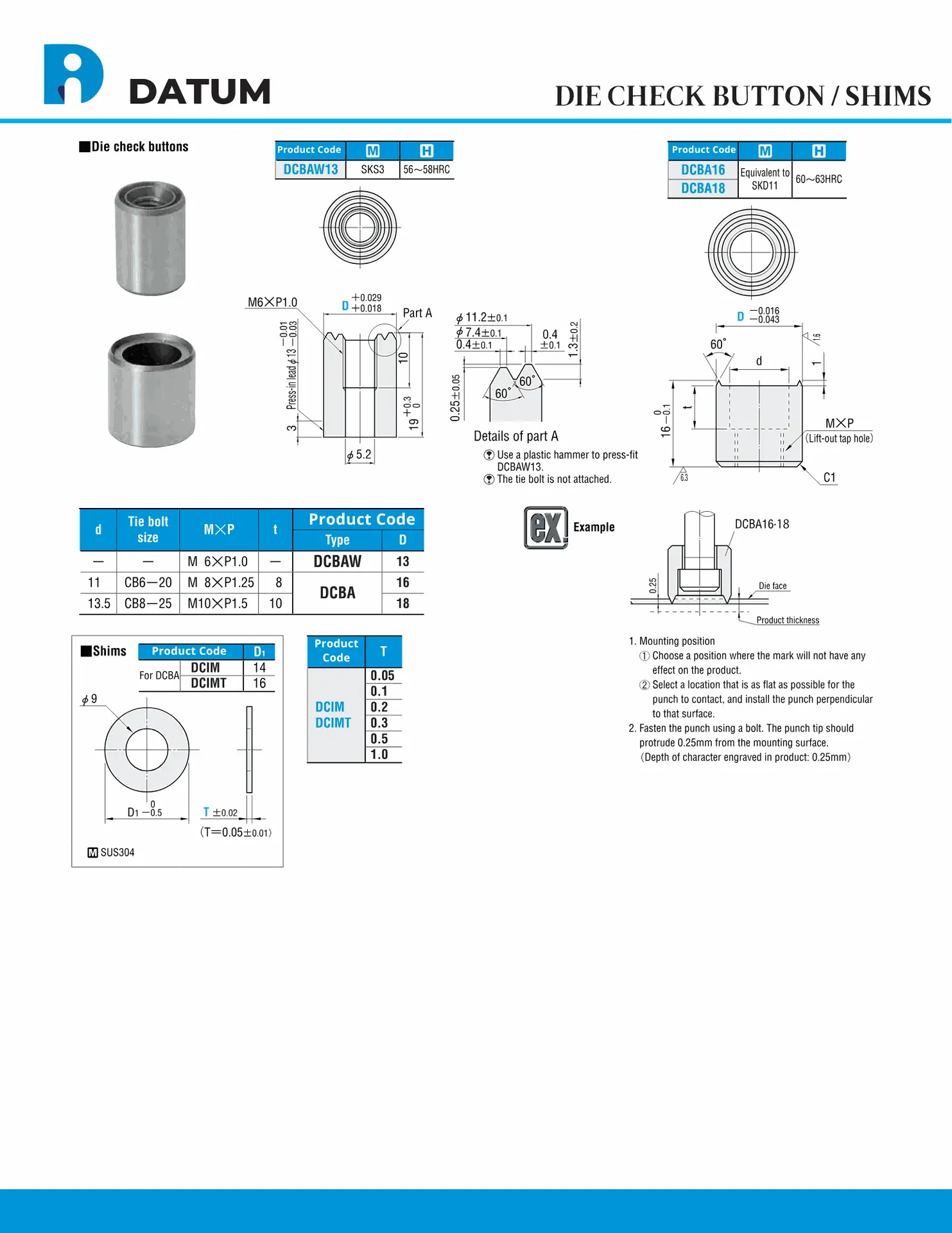

DIE CHECK BUTTON SHIMS

Die check buttons and shims are critical components in maintain position press dies, ensuring precision alignment and optimal tool performance. These elements help verify die accuracy and maintain consistent part quality during stamping operations. Crafted with high-grade materials, die check buttons and shims provide excellent durability and resistance to wear. Their design facilitates easy integration and accurate positioning, minimizing downtime and enhancing production efficiency. Ideal for automotive, aerospace, and industrial applications, these tools ensure precise die setup and reliable performance in every operation.

Die check buttons and shims are essential components used in maintain position press dies to ensure accurate die alignment and optimal functionality during production. These tools are designed to provide precise positioning and alignment, ensuring the die operates with high accuracy, leading to improved part quality and reduced operational errors.

Manufactured from high-strength materials, die check buttons and shims are highly durable and resistant to wear, even in high-pressure stamping applications. They help maintain the proper setup of the die and ensure it remains in the correct position, reducing downtime and minimizing the risk of defects in stamped parts.

These components are commonly used across various industries, including automotive, aerospace, and metal fabrication, where precision is crucial. Die check buttons and shims are designed for easy installation and can be adjusted to fit specific die configurations, ensuring seamless integration into the production process.

By using die check buttons and shims in maintain position press dies, manufacturers can achieve consistent, high-quality results, reduce setup time, and extend the lifespan of their dies. These tools are essential for any production environment that requires precise die alignment and reliable performance in every stamping operation.