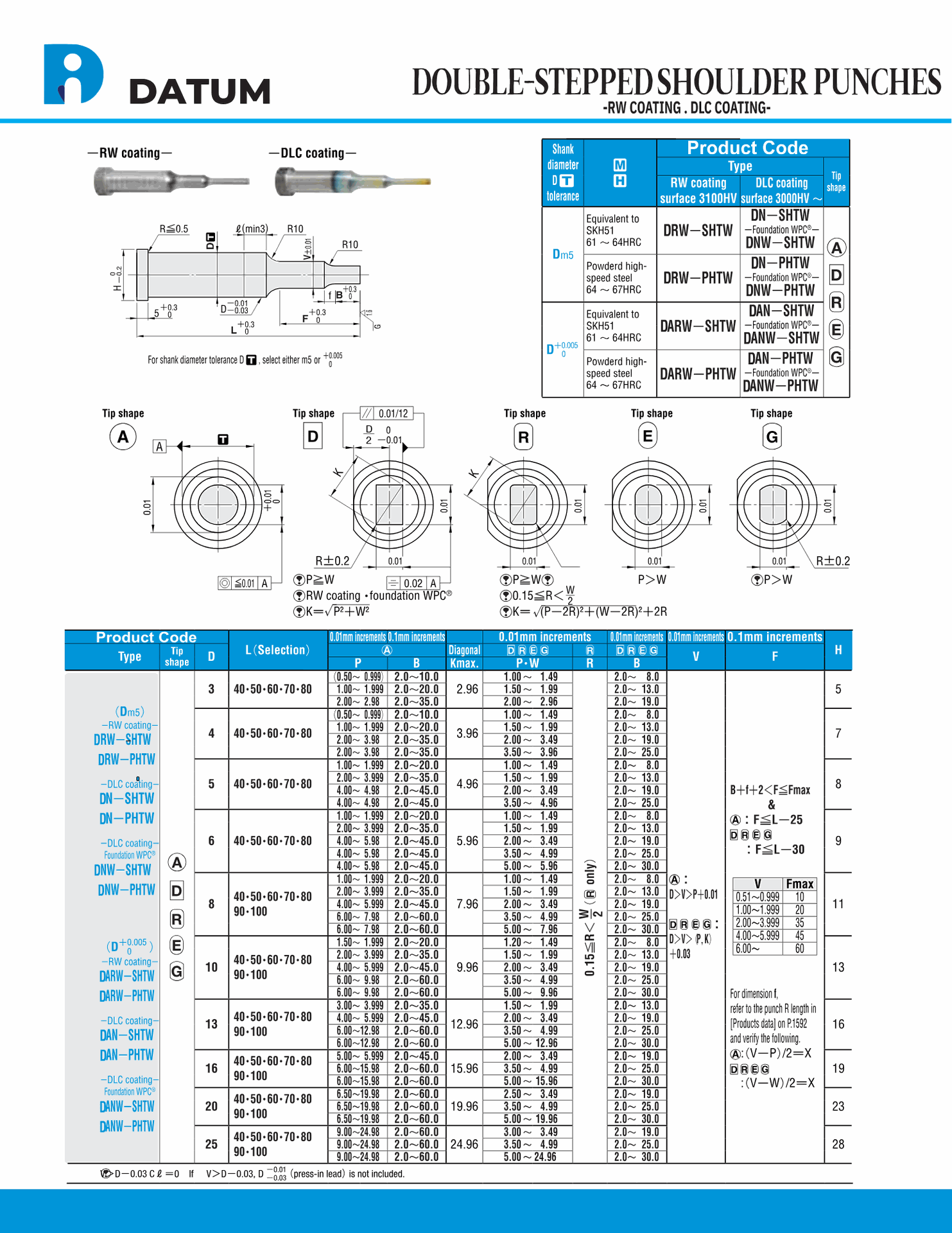

DOUBLE STEPPED SHOULDER PUNCHES

RW Coating DLC Coating

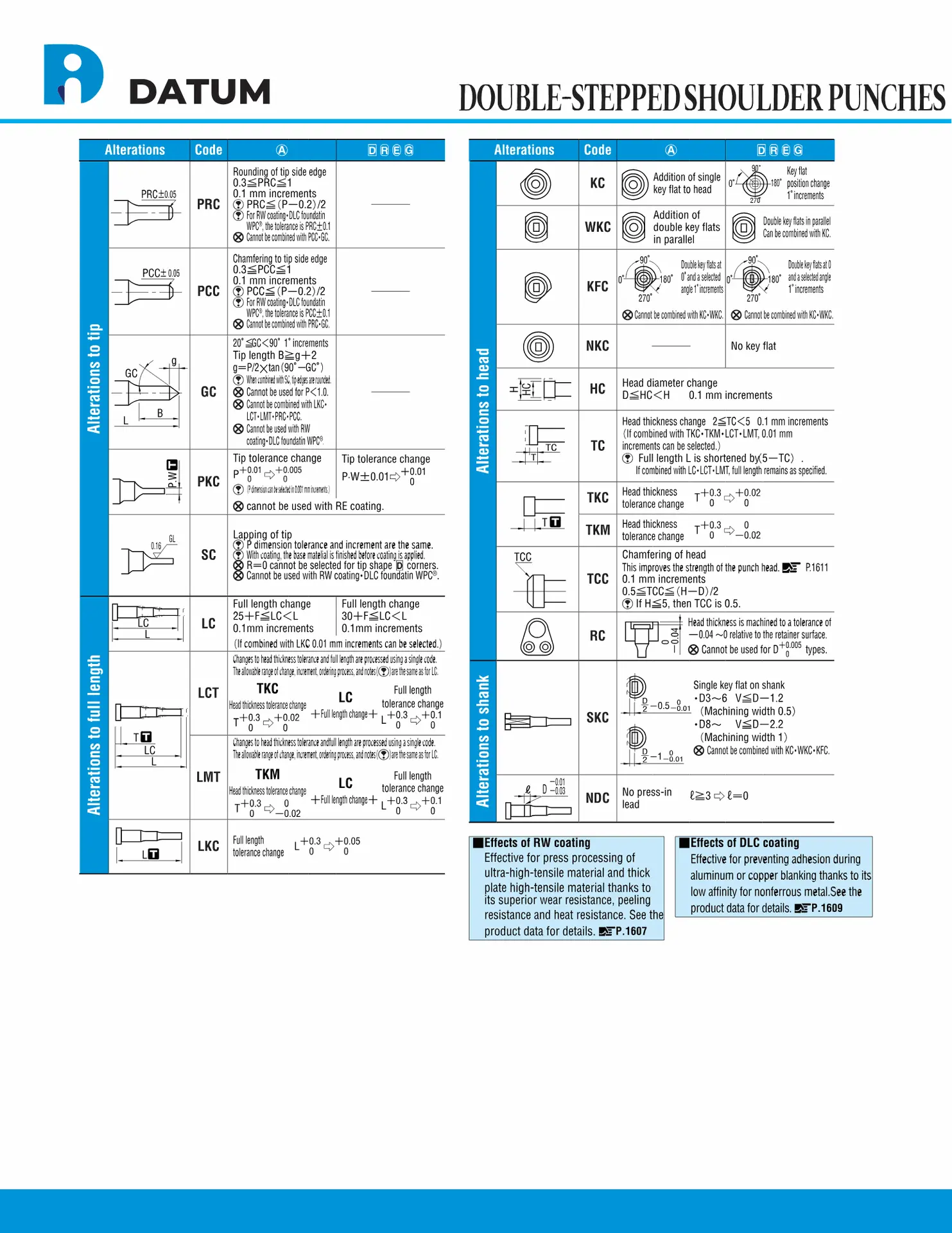

Double-Stepped Shoulder Punches with RW coating and DLC coating are designed for superior durability and performance in heavy-load press-in-die operations. The RW coating enhances wear resistance and ensures smooth functionality under high-pressure conditions. The DLC coating provides a diamond-like carbon layer, delivering exceptional hardness, low friction, and resistance to wear and corrosion. These punches ensure precise alignment and reliable performance, making them ideal for demanding industrial applications. Upgrade your tooling with these advanced punches for efficiency and long-lasting precision.

Double-Stepped Shoulder Punches with RW coating and DLC coating are engineered for precision and reliability in heavy-load press-in-die applications. The RW coating enhances wear resistance, making these punches ideal for high-pressure environments. This durable coating ensures long-term performance by reducing surface damage and maintaining consistent functionality during extended use.

The DLC coating (Diamond-Like Carbon) further elevates these punches' efficiency by providing a hard, low-friction layer resistant to wear, corrosion, and heat. This coating minimizes friction, ensuring smoother operation and extending the service life of the tooling components. These advanced coatings work in synergy to deliver unmatched durability and precision, reducing downtime and improving productivity in demanding industrial processes.

Double-Stepped Shoulder Punches are meticulously designed to maintain position and ensure seamless operation in press-in-die setups. Their robust construction and coating options make them a valuable addition to any manufacturing setup, providing reliable performance under challenging conditions.

Invest in Double-Stepped Shoulder Punches with RW and DLC coatings to enhance tooling performance, reduce maintenance costs, and achieve superior results in your industrial processes.