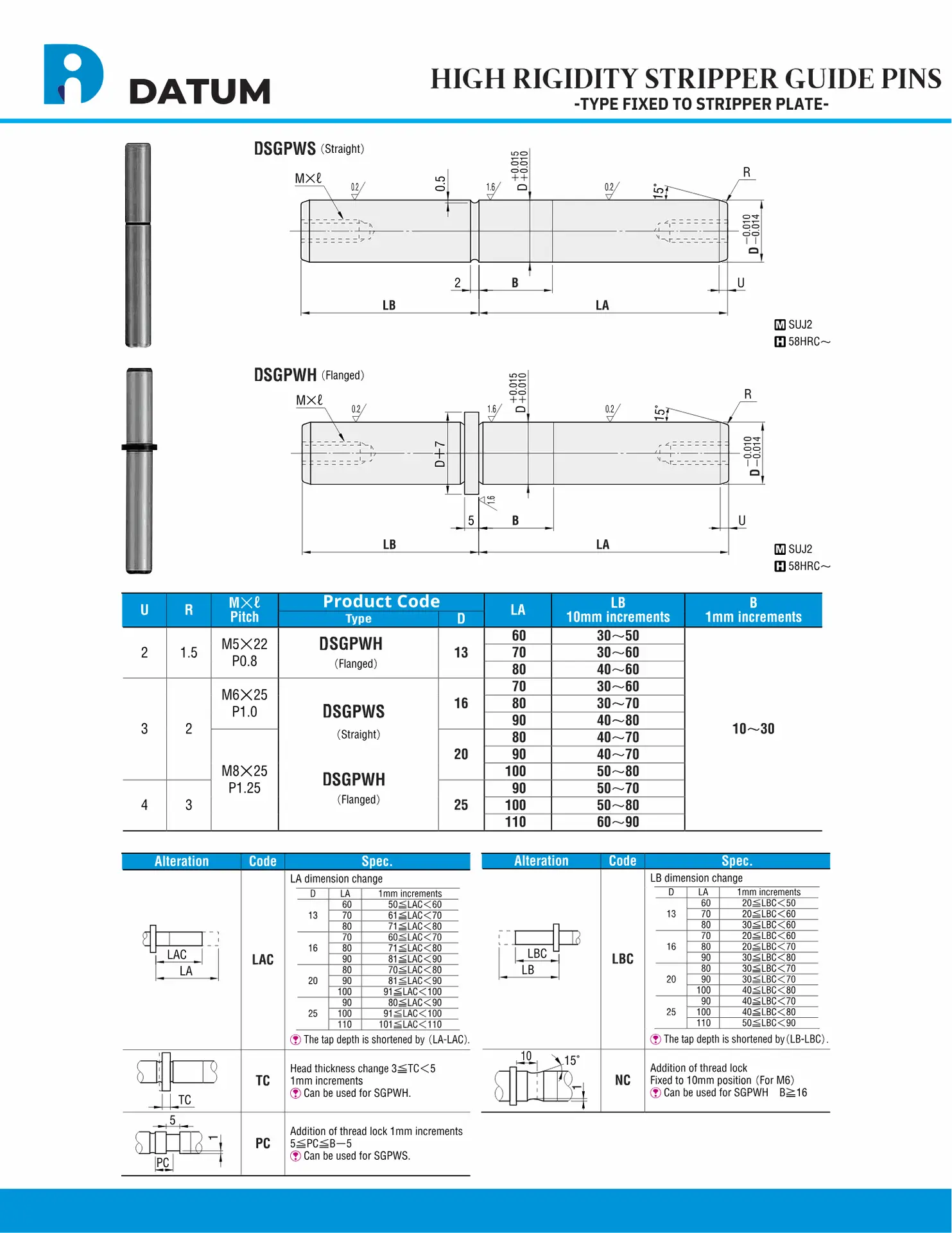

HIGH RIGIDITY STRIPPER GUIDE PINS

Type Fixed To Stripper Plate

High rigidity stripper guide pins fixed to the stripper plate are engineered for precision and durability in maintain position press-in-die applications. Designed to handle heavy loads, these guide pins ensure precise alignment of tooling during stamping processes, reducing wear and tear on the die and components. Their high rigidity enhances stability, allowing for consistent and accurate performance, even under high-pressure conditions. Ideal for industries such as automotive and aerospace, these stripper guide pins improve productivity and ensure long-lasting tool performance.

High rigidity stripper guide pins fixed to the stripper plate are essential components for maintain position press-in-die applications, offering unmatched precision and durability in high-pressure stamping and forming processes. These guide pins are specifically designed to ensure perfect alignment of dies, preventing misalignment and wear during operations. Their robust design allows them to withstand heavy loads, providing stability and accuracy in even the most demanding industrial environments.

Manufactured with high-quality materials, high rigidity stripper guide pins minimize the risk of deformation, ensuring that the die and tooling remain precisely positioned throughout the stamping cycle. This reduces friction and extends the lifespan of the die and associated components. These pins are ideal for industries like automotive, aerospace, and manufacturing, where performance and longevity are critical.

By using high rigidity stripper guide pins, manufacturers can enhance the efficiency of their die maintenance and press processes, improving product quality and reducing downtime. Whether you're looking for a reliable solution for heavy-duty stamping or precise tool alignment, high rigidity stripper guide pins offer the perfect solution to maintain the integrity and performance of your press-in-die operations.