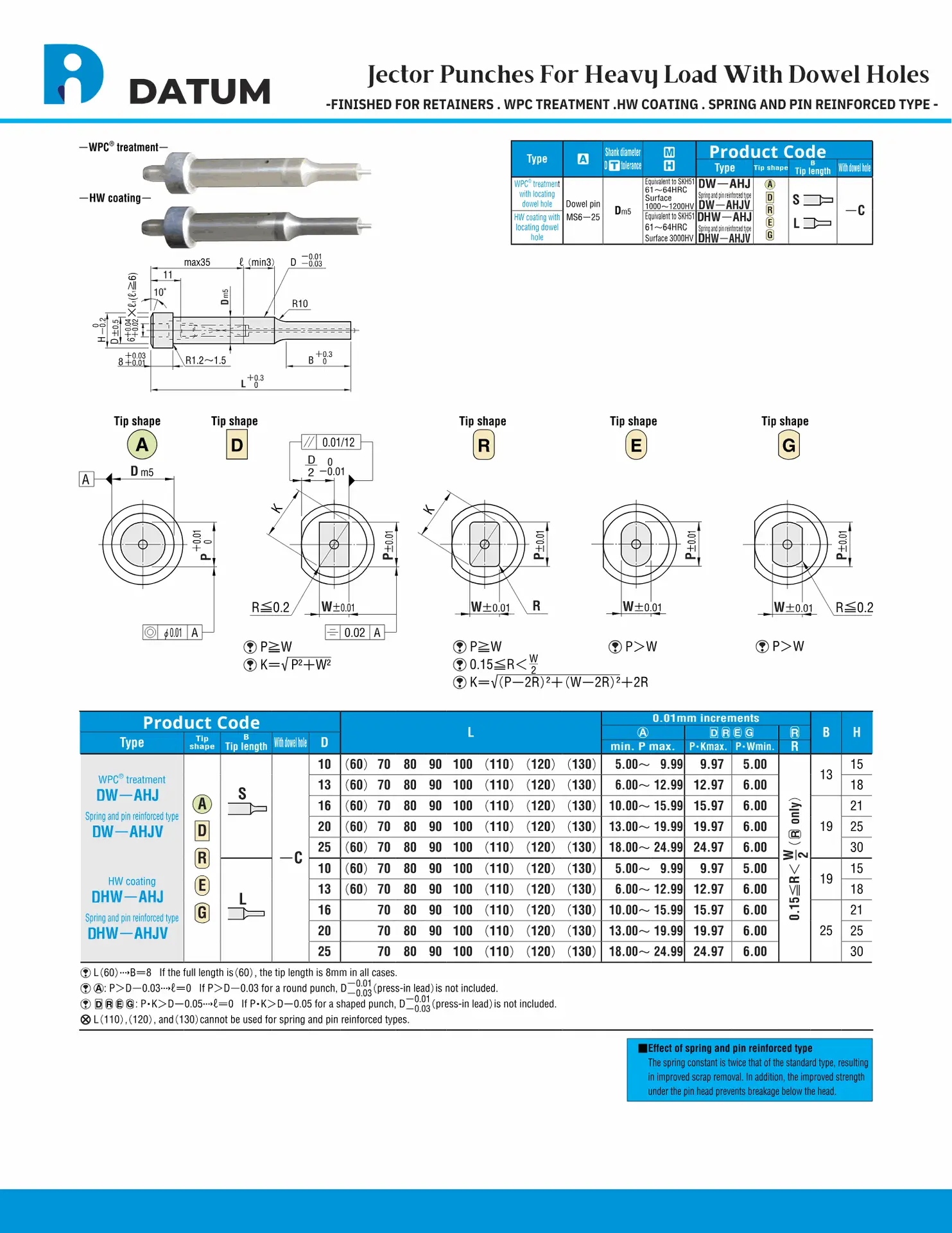

Jector Punches For Heavy Load With Dowel Holes

Finished For Retainer WPC Treatment HW Coating Spring And Pin Reinforced Type

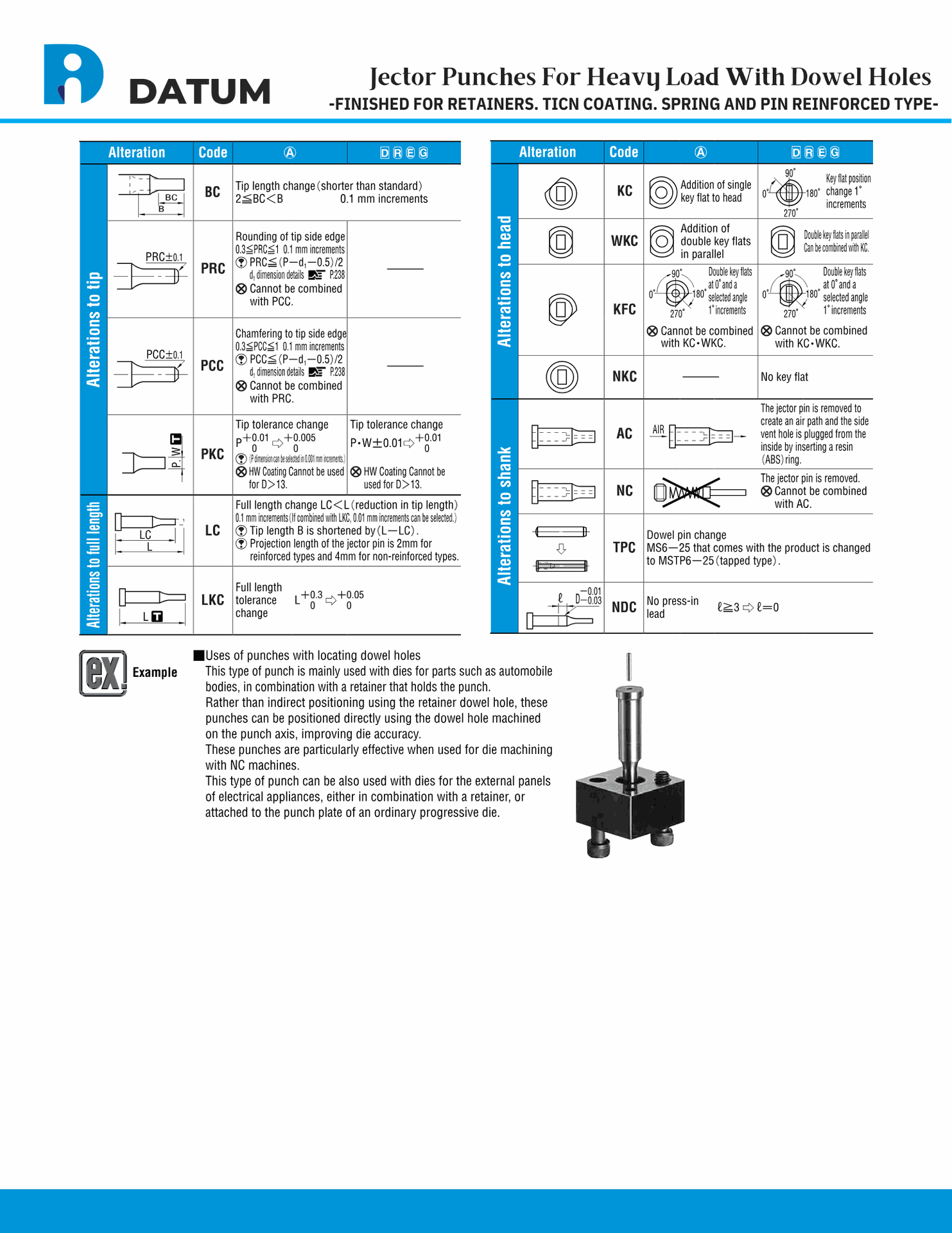

Jector Punches for Heavy Load with Dowel Holes, finished for retainers with WPC treatment, HW coating, and spring and pin reinforced type, are engineered for optimal performance in press-in-die applications. The WPC treatment enhances the hardness and durability of the punches, while the HW coating offers superior wear and corrosion resistance. The spring and pin reinforced design ensures increased stability and longevity under heavy loads. These punches are perfect for maintaining position in die sets, providing exceptional precision, strength, and reliability in demanding industrial environments.

Jector Punches for Heavy Load with Dowel Holes, finished for retainers with WPC treatment, HW coating, and spring and pin reinforced type, are designed to deliver exceptional strength, durability, and precision in maintaining position within press-in-die applications. The WPC treatment improves the hardness and toughness of the punches, making them resistant to wear and damage, even under heavy loads. The HW coating offers superior protection against corrosion, extending the lifespan of the punches in harsh environments.

The spring and pin reinforced design further enhances the stability of the punches, ensuring they maintain accurate alignment during high-pressure operations. This feature is especially beneficial for industries requiring precise die alignment and optimal performance in heavy-duty press work.

These jector punches are ideal for manufacturers looking to improve the longevity and efficiency of their stamping and punching operations. The combination of WPC treatment, HW coating, and reinforced design makes these punches the perfect choice for heavy-load applications in die maintenance. Whether for automotive, metalworking, or other industrial sectors, these punches provide reliable and consistent results, even in the most demanding environments.