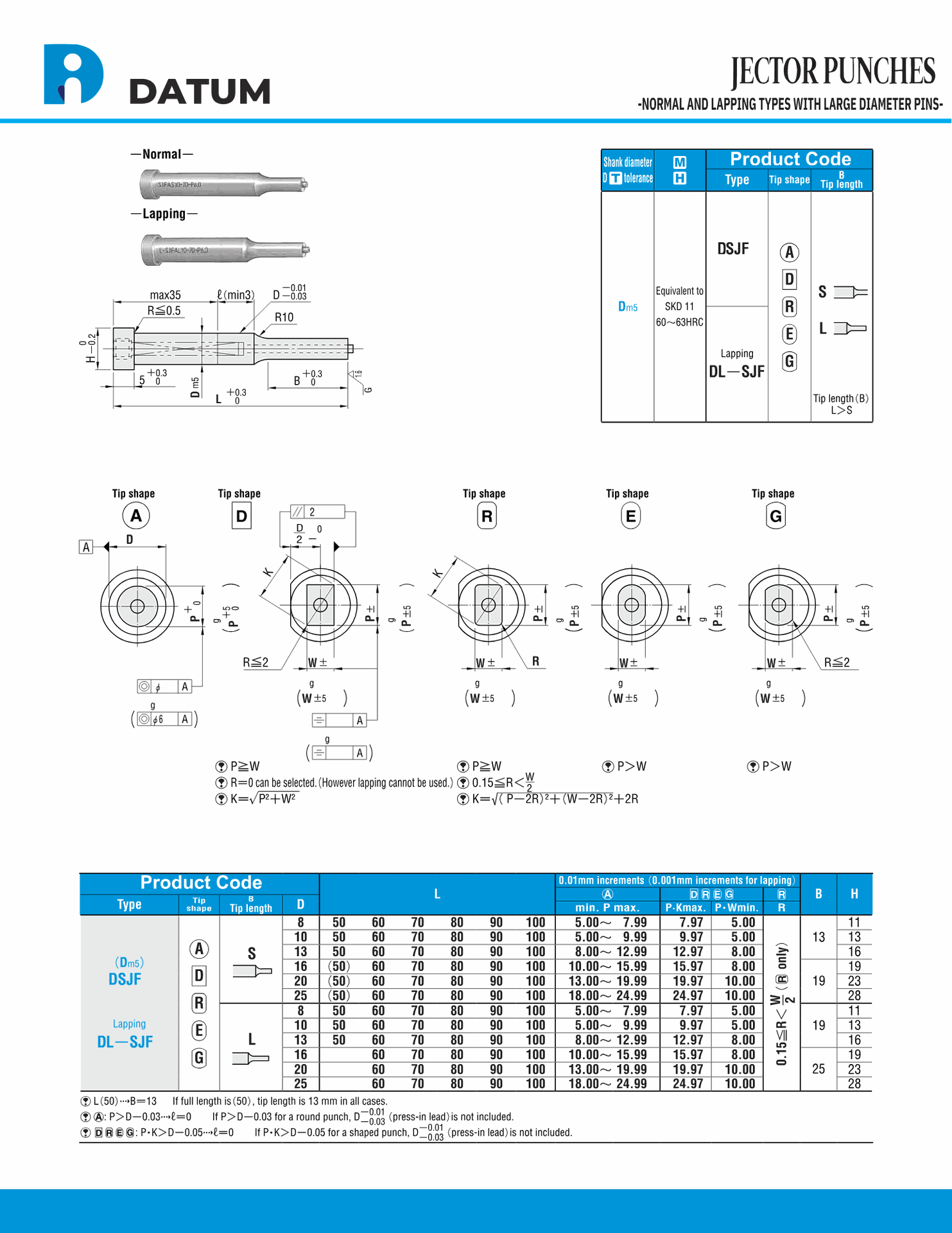

JECTOR PUNCHES

Normal And Lapping Types With Large Diameter Pins

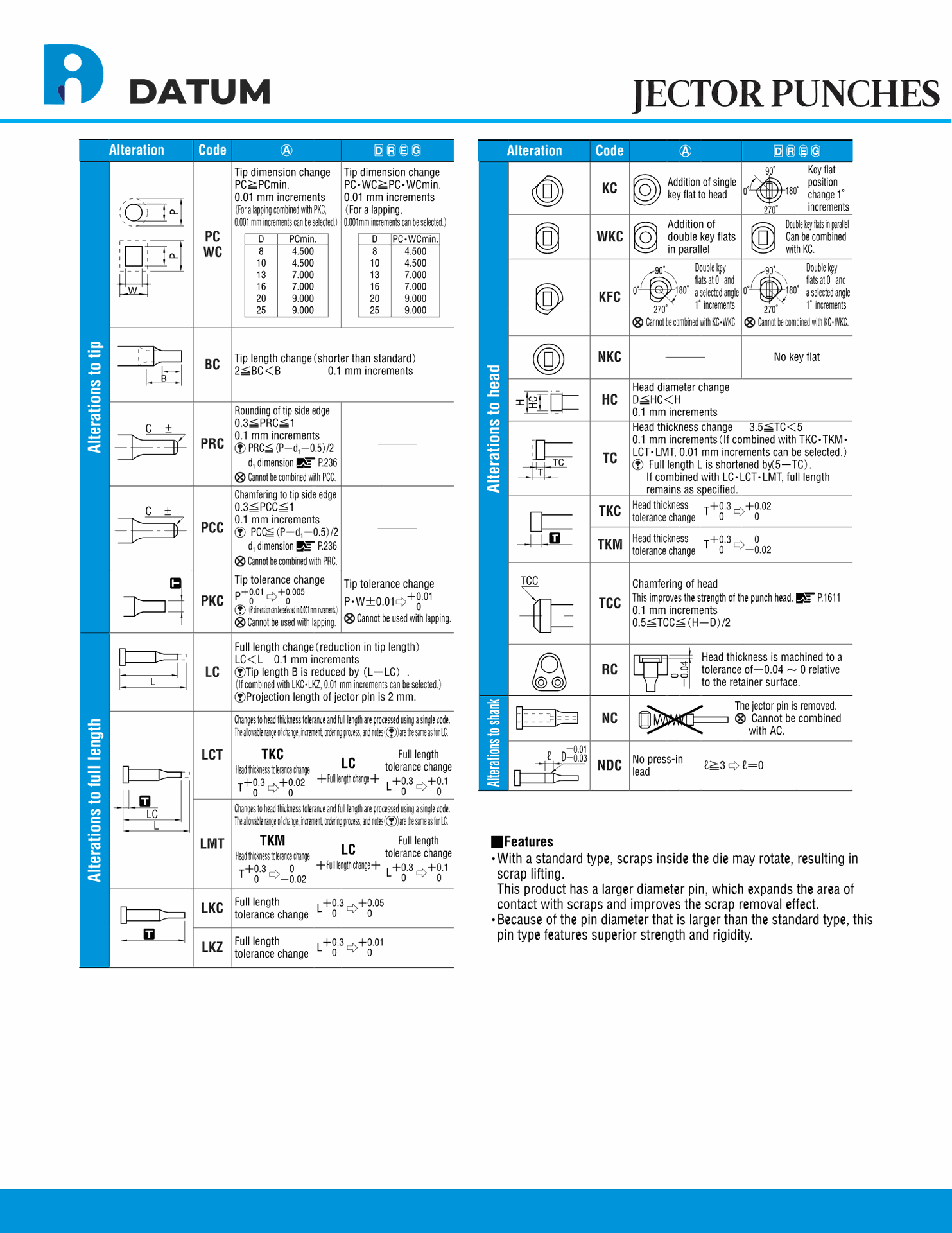

Jector Punches, available in Normal and Lapping types with large diameter pins, are designed for heavy-duty, maintain position press-in-die applications. These punches ensure precise alignment and enhanced performance under high-pressure conditions. The large diameter pins offer superior strength and stability, preventing bending and misalignment during operation. With their durable construction and exceptional reliability, Jector Punches improve production efficiency and reduce downtime. Ideal for industries requiring precision and durability, these punches are built to withstand the toughest conditions while ensuring consistent, high-quality results.

Jector Punches in Normal and Lapping types with large diameter pins are engineered for heavy-duty applications, particularly in maintain position press-in-die operations. These high-performance punches are designed to offer optimal precision, durability, and efficiency under challenging conditions. The large diameter pins provide additional strength, enhancing the punch’s ability to withstand high forces and prevent misalignment or bending, which is crucial for maintaining consistent and accurate results during the pressing process.

Ideal for industries that require precise and reliable punching solutions, these Jector Punches reduce maintenance needs, minimizing downtime and increasing overall productivity. The Normal and Lapping types ensure versatility, allowing users to select the perfect punch type based on specific needs and material requirements. The robust construction of these punches guarantees longevity and reduces wear, making them an excellent choice for both low and high-volume production environments.

Whether you're dealing with metals, plastics, or other tough materials, Jector Punches with large diameter pins are built to maintain performance even under the most demanding conditions. With improved alignment and superior durability, these punches are an essential tool for companies looking to optimize their die stamping processes while ensuring high-quality outcomes consistently.