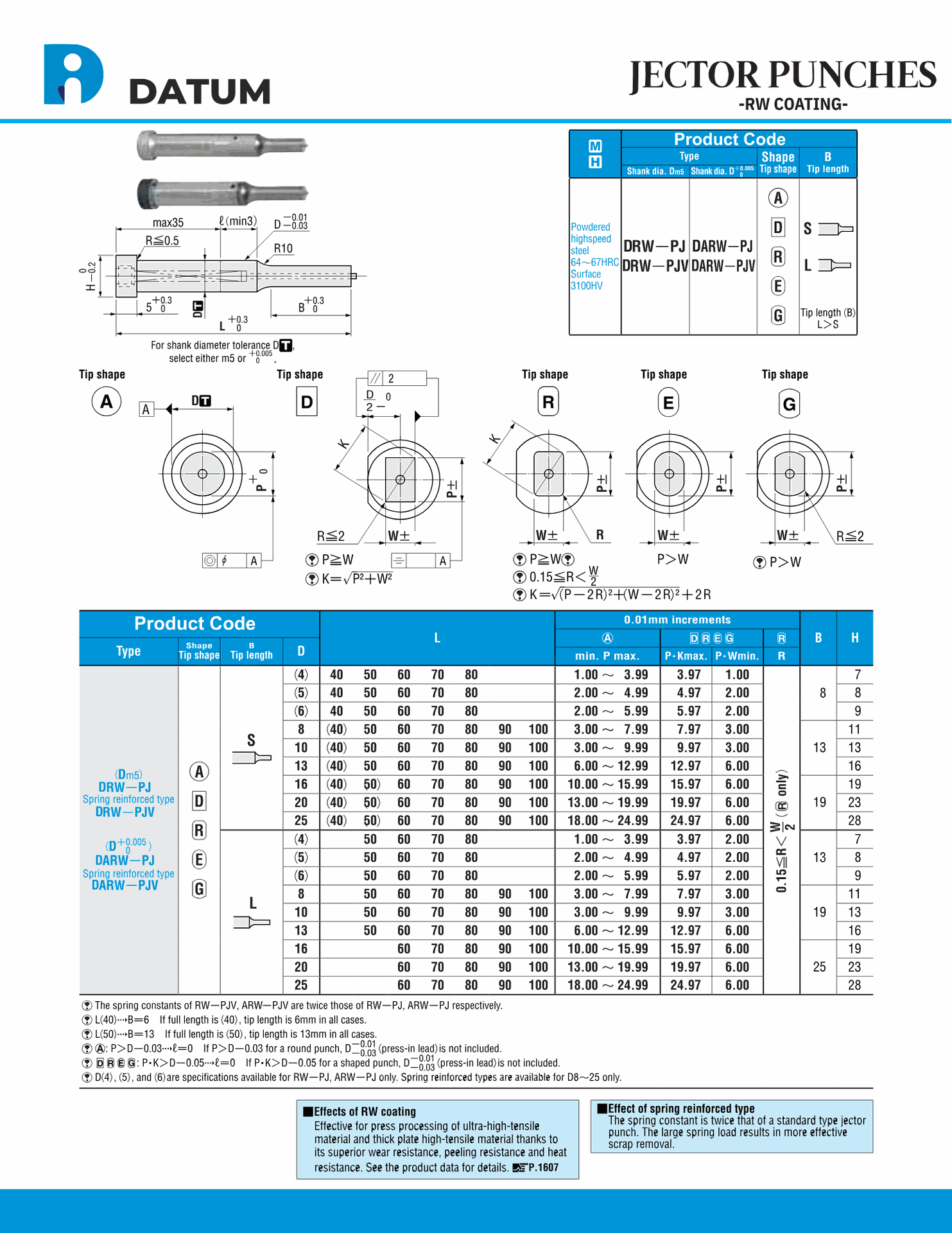

JECTOR PUNCHES

RW Coating

Jector Punches with RW Coating are designed to enhance performance in heavy-load applications during press-in-die operations. The RW (Redundant Wear) coating provides superior wear resistance, protecting the punches from corrosion, abrasion, and tool degradation. These punches maintain their position and integrity under high-pressure conditions, ensuring precise and efficient metalworking. Ideal for industries requiring durable tools, Jector Punches with RW Coating increase tool life and reduce maintenance costs, ultimately improving operational productivity. Choose Jector Punches with RW Coating for long-lasting, reliable performance in demanding environments.

Jector Punches with RW Coating are engineered for optimal performance in high-load applications within press-in-die operations. The RW (Redundant Wear) Coating provides excellent protection against wear and tear, corrosion, and abrasion, making these punches ideal for industries that demand precision and durability under extreme conditions. Designed to maintain position and withstand heavy loads, Jector Punches with RW Coating ensure consistent, reliable results in metalworking, stamping, and die-casting applications.

These punches not only offer enhanced durability but also contribute to improved tool life, reducing the need for frequent replacements. With their superior wear resistance, Jector Punches with RW Coating help minimize downtime, increasing productivity and operational efficiency. The coating also supports high-performance operations, ensuring the punches maintain their integrity even under sustained use in press-in-die processes.

By choosing Jector Punches with RW Coating, manufacturers can rely on a trusted solution to enhance production quality while reducing maintenance costs. Whether you're working in automotive, aerospace, or heavy machinery manufacturing, these punches deliver top-tier performance and longevity. Invest in Jector Punches with RW Coating for outstanding performance, reduced tool wear, and increased production uptime.