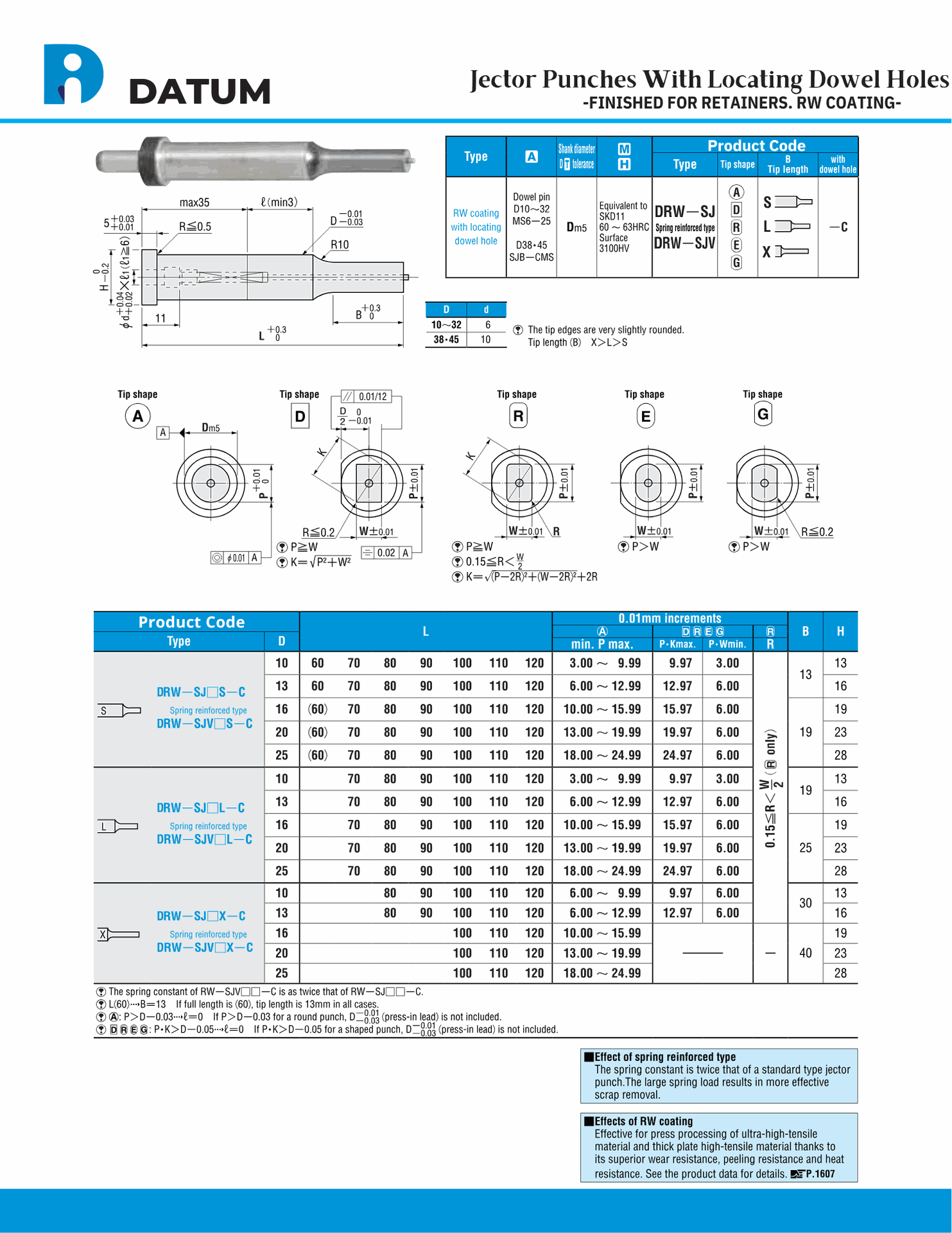

Jector Punches With Locating Dowel Holes

Finished For Retainers RW Coating

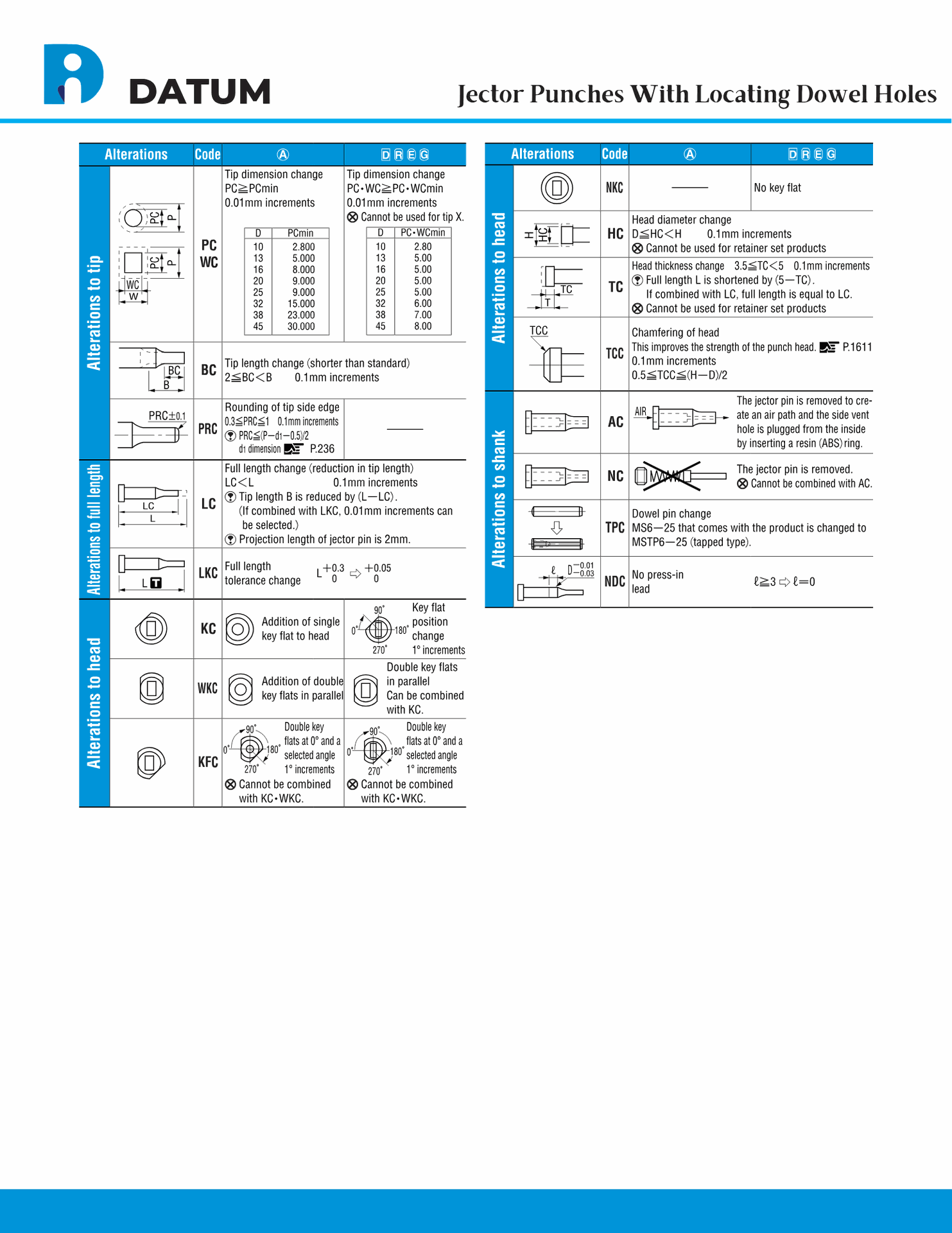

Jector Punches with Locating Dowel Holes, finished for retainers with RW Coating, are designed for precision and durability in maintain-position press-in-die applications. The advanced RW Coating enhances surface hardness, wear resistance, and reduces friction, ensuring extended tool life and consistent performance in demanding environments. Locating dowel holes provide accurate alignment, minimizing setup time and improving efficiency. Ideal for industries like automotive and aerospace, these punches deliver exceptional reliability and performance, making them a trusted choice for high-precision metalworking operations.

Jector Punches with Locating Dowel Holes, finished for retainers with RW Coating, are designed to deliver precision, durability, and reliability in maintain-position press-in-die applications. These high-performance punches are tailored to meet the rigorous demands of metalworking industries, providing exceptional alignment and operational accuracy.

The RW Coating (Robust Wear Coating) enhances the surface hardness and wear resistance of the punches, making them ideal for heavy-duty operations. This specialized coating reduces friction and minimizes wear during repeated cycles, ensuring extended tool life and consistent performance. The RW Coating also offers excellent resistance to corrosion and heat, enabling the punches to withstand challenging industrial environments.

The addition of locating dowel holes ensures precise alignment and repeatable accuracy, reducing setup time and improving productivity. This feature is particularly advantageous in high-precision applications, where even minor misalignments can compromise quality and efficiency.

These punches are engineered for optimal performance in various industries, including automotive, aerospace, and general manufacturing. By combining advanced coating technology with robust construction, Jector Punches with RW Coating offer superior durability, reduced downtime, and improved cost efficiency, making them an essential choice for press-in-die applications requiring precise positioning and long-lasting reliability.