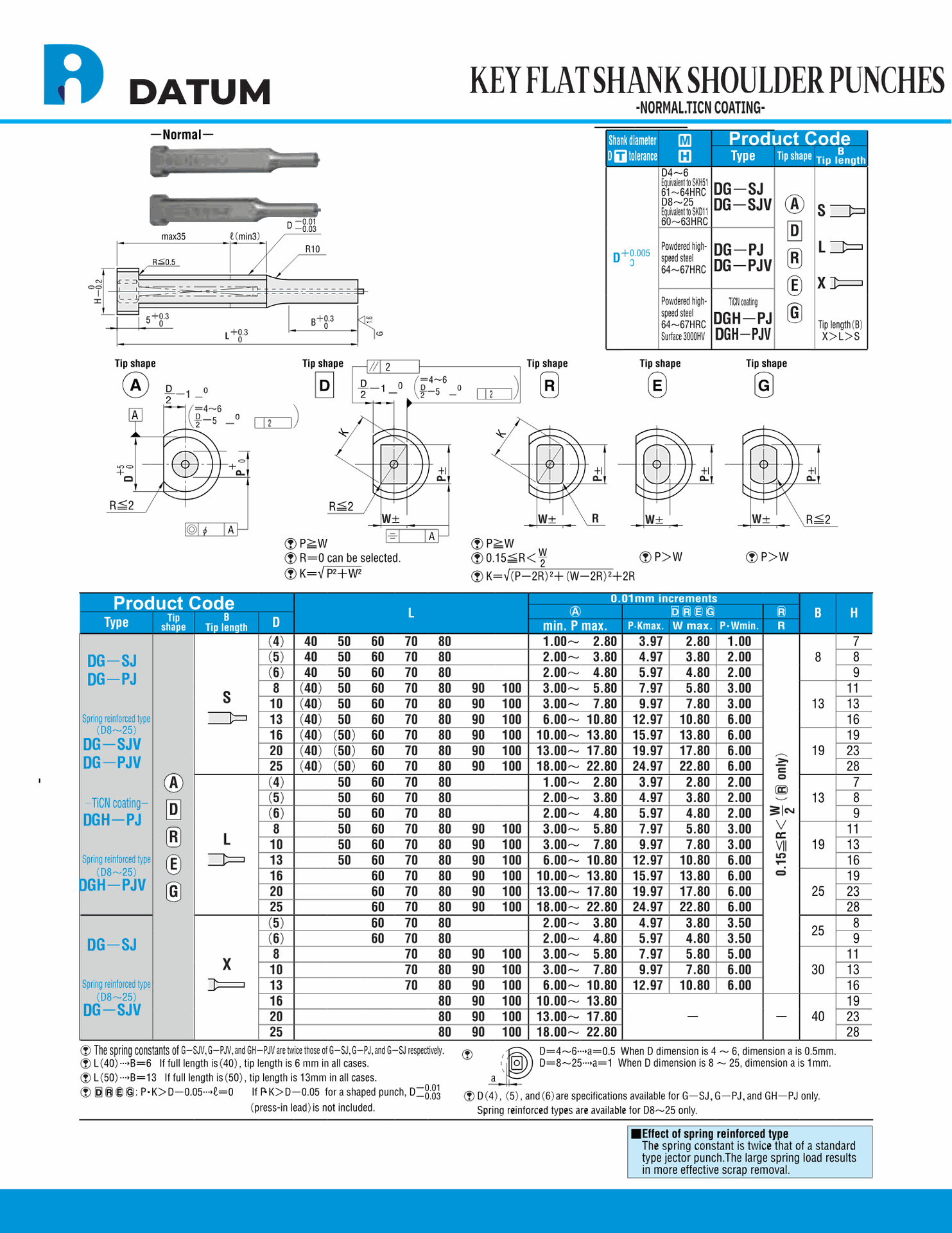

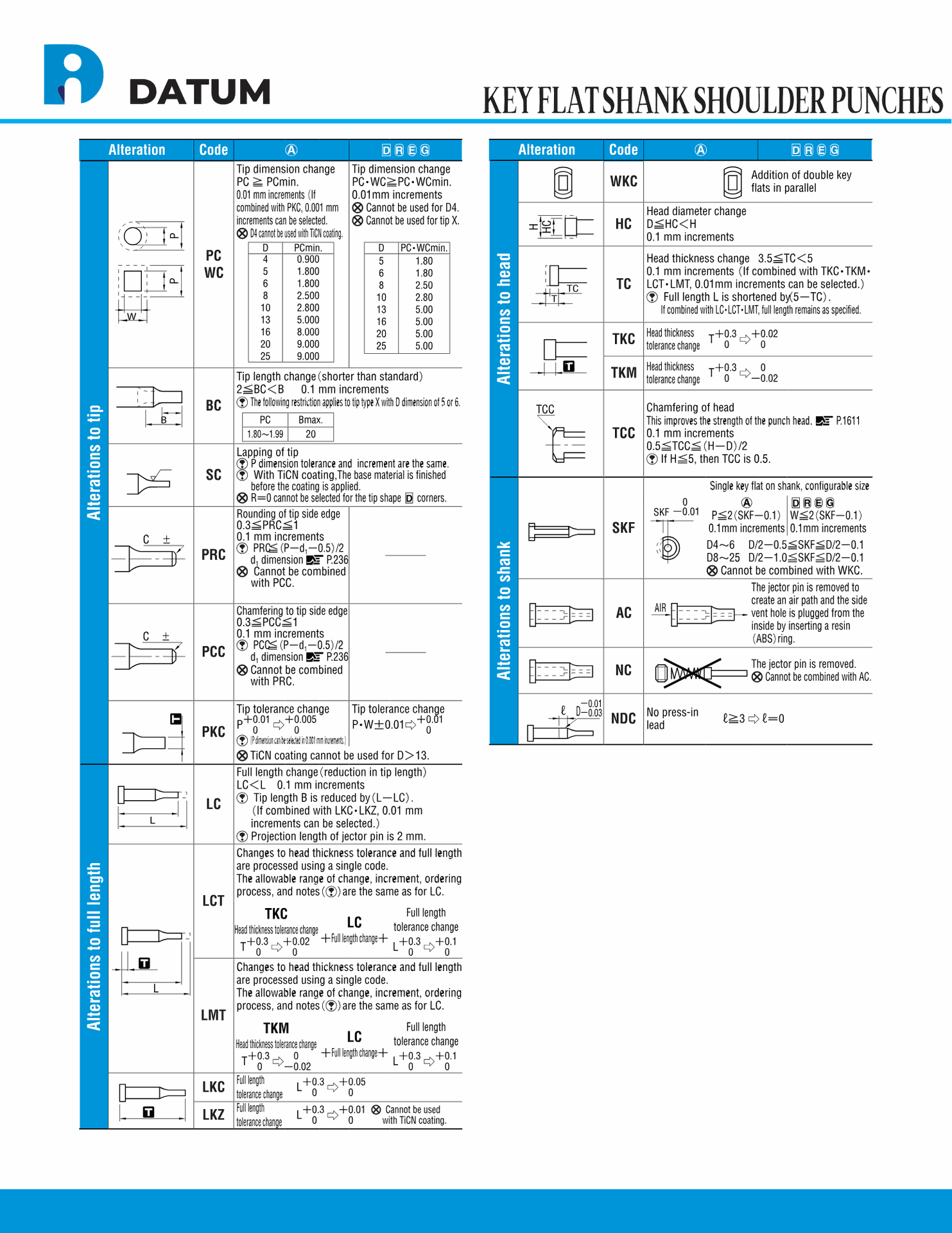

KEY FLAT SHANK SHOULDER PUNCHES

Normal Ticn Coating

Key Flat Shank Shoulder Punches with Normal TiCN Coating are designed for superior performance in press-in-die applications. The TiCN Coating enhances wear resistance and ensures a longer tool life, even under heavy loads and high-pressure conditions. The key flat shank design provides excellent alignment and stability, maintaining precise positioning during operation. These punches are ideal for industries requiring consistent accuracy and durability in manufacturing processes. Upgrade your tooling with these reliable and efficient punches for optimal results.

Key Flat Shank Shoulder Punches with Normal TiCN Coating are engineered for exceptional performance in high-demand press-in-die applications. The TiCN (Titanium Carbonitride) coating significantly enhances wear resistance, making these punches durable even under heavy loads and abrasive working conditions. This advanced coating minimizes friction, reduces wear, and extends the service life of the punches, ensuring reliable and consistent performance over time.

The key flat shank design offers superior alignment and stability during operation, preventing rotational movement and maintaining precise positioning within the die. This feature is crucial for industries requiring high precision and accuracy, such as automotive, aerospace, and metal fabrication. These punches are ideal for applications involving repetitive or high-pressure operations, where maintaining alignment is critical.

Manufactured with top-quality materials and precise engineering, these punches ensure optimal compatibility with a variety of die setups. Whether you're working on intricate stamping or heavy-duty forming, Key Flat Shank Shoulder Punches with Normal TiCN Coating deliver unmatched reliability and performance.

Upgrade your tooling with these durable punches to improve efficiency, reduce downtime, and achieve superior results in your manufacturing processes. Experience the benefits of advanced coating technology and precision engineering