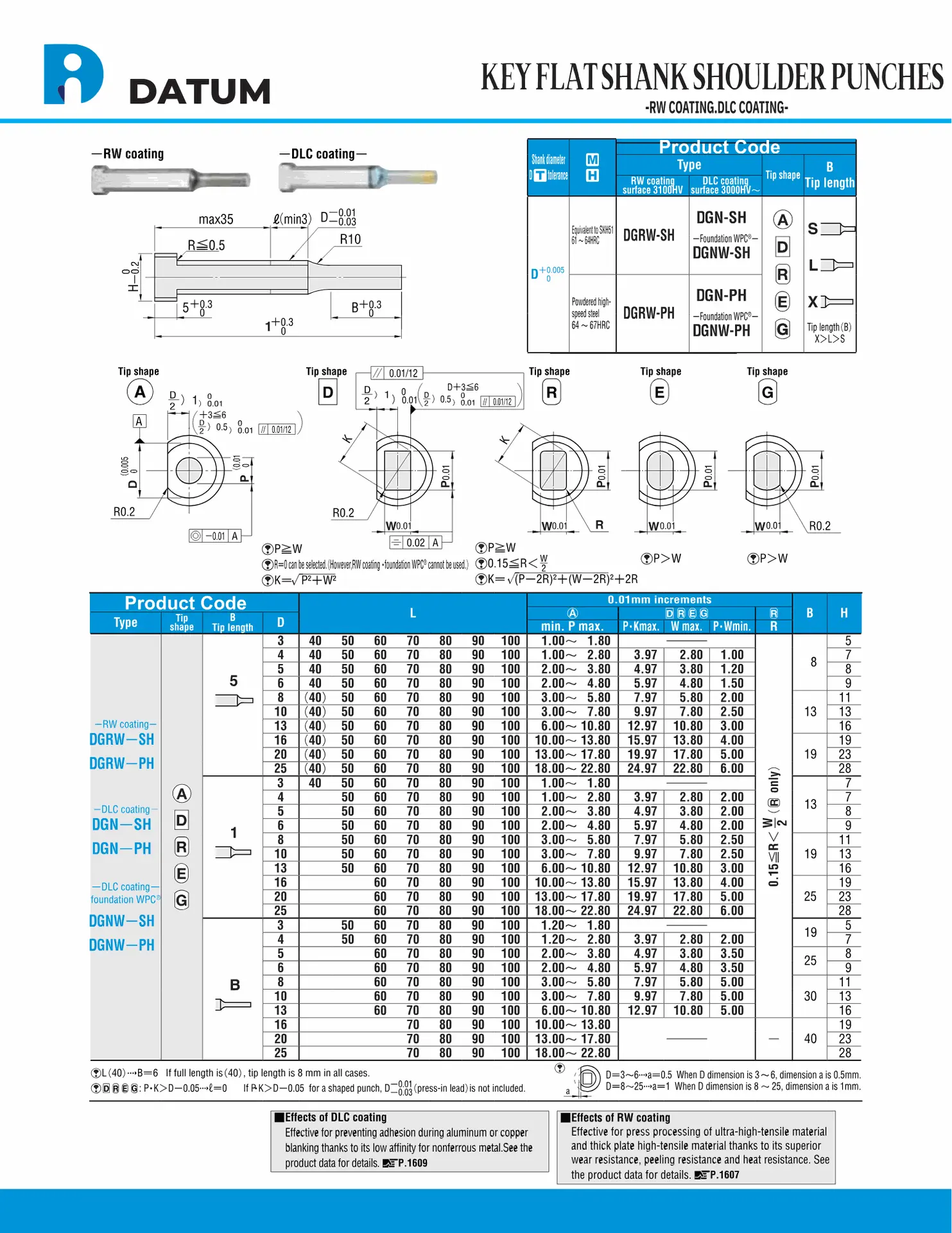

KEY FLAT SHANK SHOULDER PUNCHES

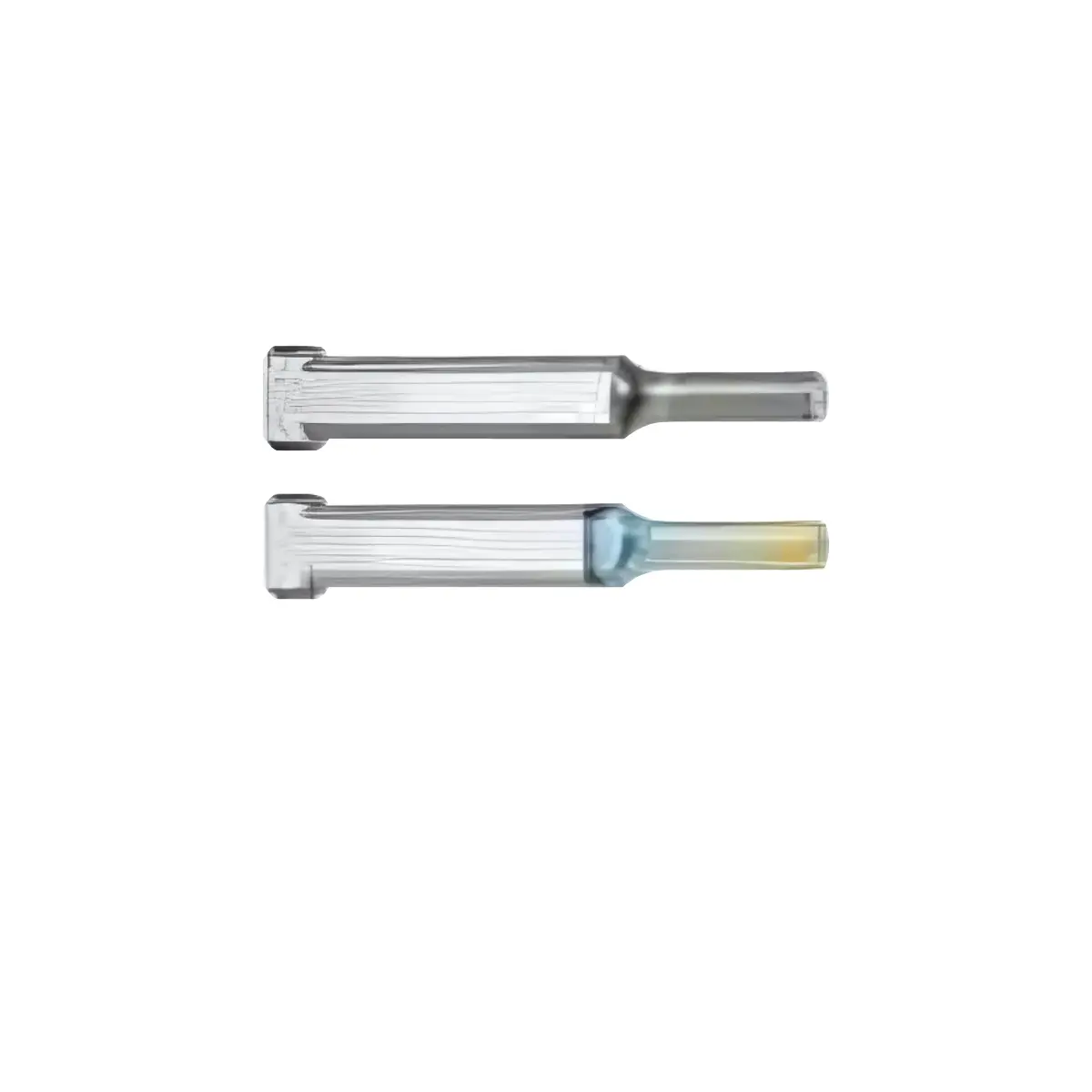

RW Coating DLC Coating

Key Flat Shank Shoulder Punches with RW Coating and DLC Coating are designed for superior performance in press-in-die applications. The RW coating enhances wear resistance, while the DLC coating provides a low-friction surface for smoother operations and extended tool life. These coatings ensure high precision and durability, even under heavy loads.The key flat shank design ensures secure positioning and prevents misalignment during operation, making these punches ideal for demanding industries requiring consistent performance and reliability.

Key Flat Shank Shoulder Punches with RW Coating and DLC Coating are engineered for precision and durability in high-performance press-in-die applications. These punches are specifically designed to withstand heavy loads while maintaining their structural integrity and delivering consistent results.

The RW Coating provides exceptional wear resistance, making the punches ideal for prolonged use in demanding conditions. The DLC Coating offers a low-friction surface, reducing heat generation and minimizing wear during high-speed operations. Together, these coatings enhance the longevity and efficiency of the punches, ensuring smoother operations and reduced downtime.

The key flat shank design ensures a secure fit and maintains precise alignment within the die, preventing misalignment or operational errors. This makes them a reliable choice for industries requiring exacting tolerances and consistent output.

Whether used in automotive, aerospace, or industrial manufacturing, Key Flat Shank Shoulder Punches with RW and DLC coatings deliver unmatched performance, reliability, and efficiency. Invest in these high-quality punches to optimize your production processes and achieve superior results.