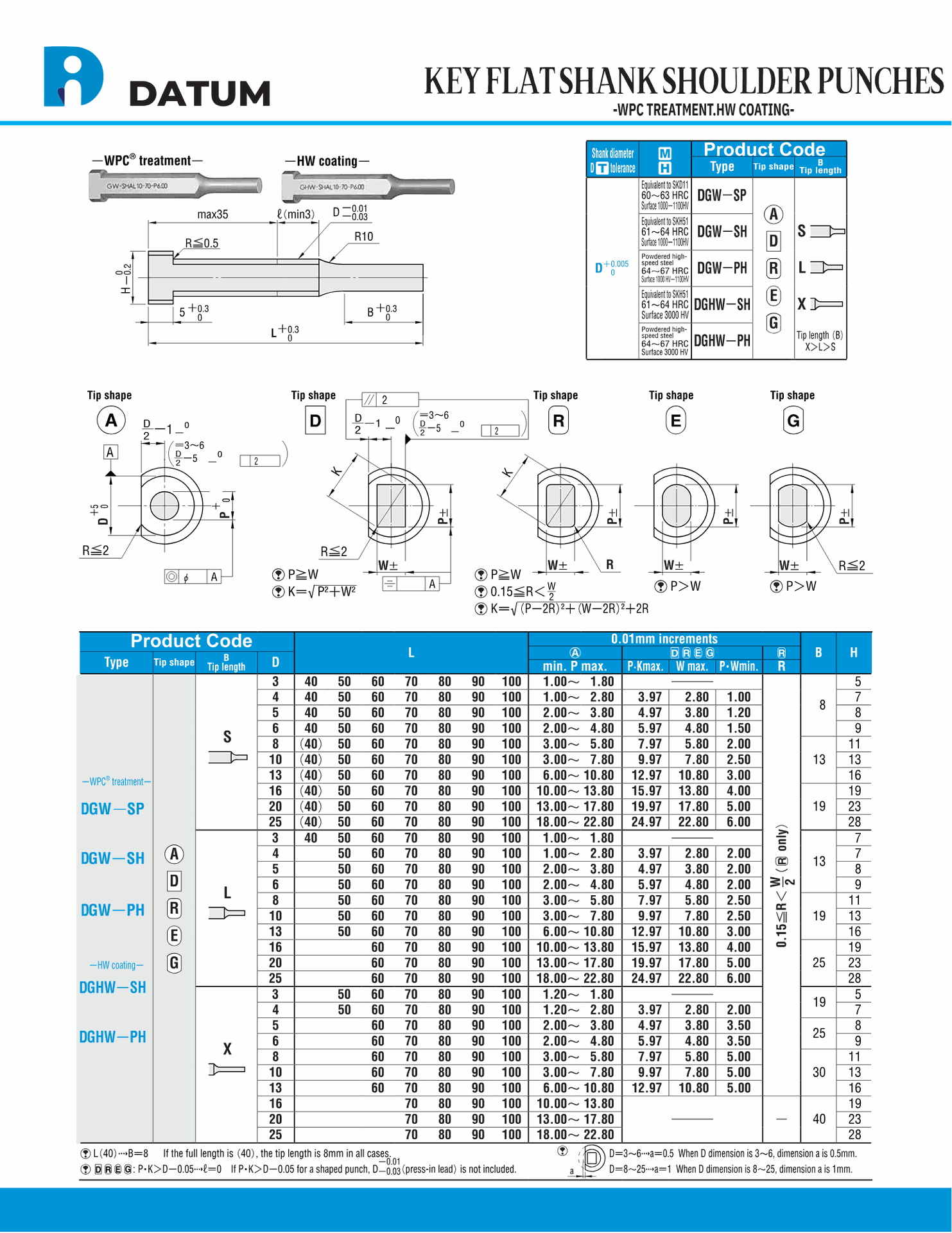

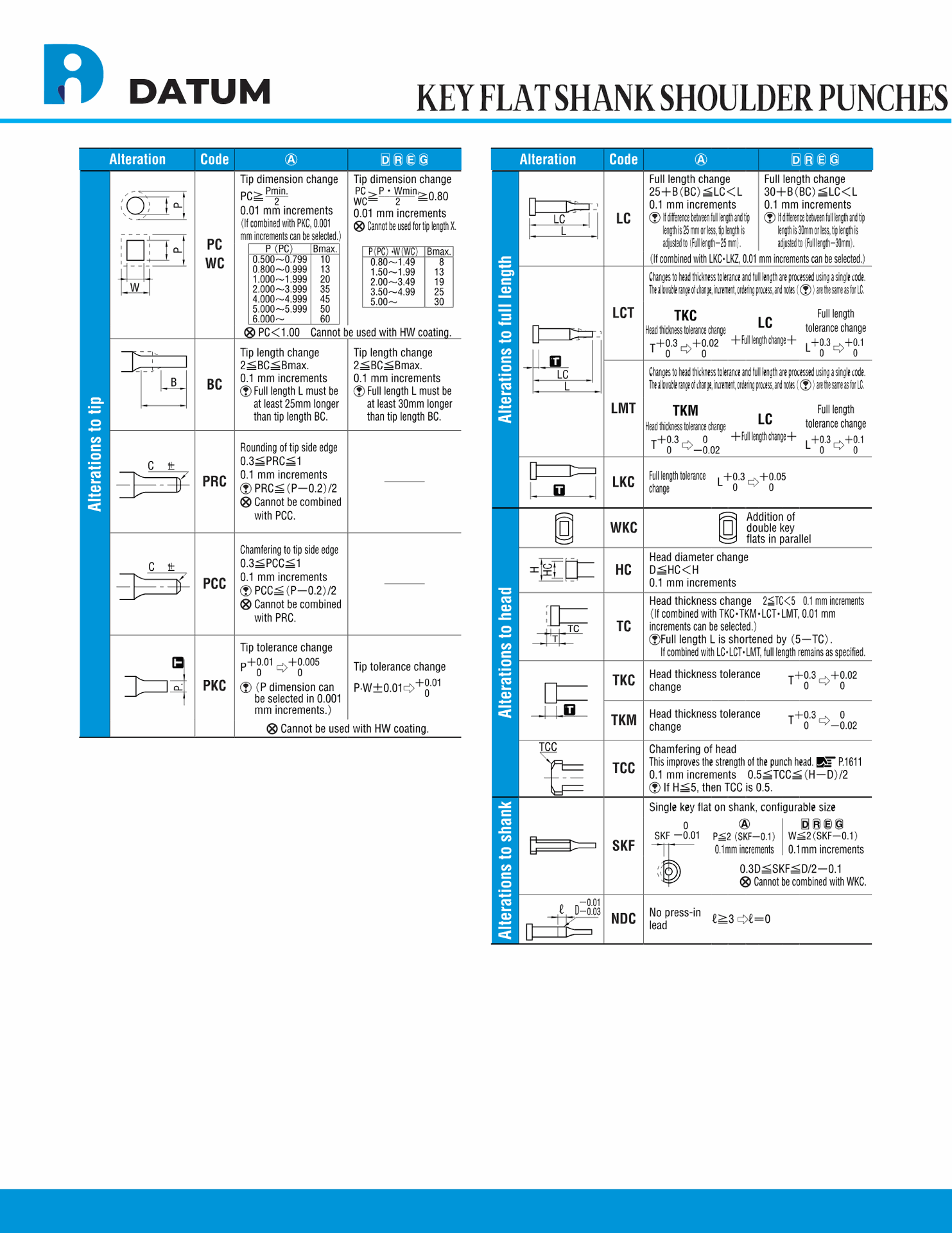

KEY FLAT SHANK SHOULDER PUNCHES

WPC Treatment HW Coating

Key Flat Shank Shoulder Punches featuring WPC Treatment and HW Coating are expertly designed for precision in maintaining position during press-in-die operations. The WPC treatment enhances surface durability and reduces friction, while the HW coating provides superior hardness and wear resistance, ensuring reliable performance under heavy loads. These punches offer exceptional stability, accurate positioning, and extended tool life, making them ideal for high-precision manufacturing applications. Optimize efficiency and ensure consistent results with these advanced, high-performance shoulder punches.

Key Flat Shank Shoulder Punches with WPC Treatment and HW Coating are engineered to deliver exceptional durability and precision in press-in-die applications. The WPC treatment enhances surface resilience, reducing friction and minimizing wear during high-load operations. Combined with the advanced HW Coating, these punches provide superior hardness, extending tool life even in demanding manufacturing environments.

Designed for optimal performance, these shoulder punches ensure accurate positioning and stability during operation, maintaining consistent results and reducing downtime. The key flat shank design offers secure mounting, preventing rotation or misalignment for reliable operation. This makes them ideal for industries requiring precision tooling, such as automotive, aerospace, and heavy machinery manufacturing.

By incorporating these punches into your die setup, you benefit from reduced maintenance costs, improved operational efficiency, and consistent production quality. Whether handling repetitive tasks or managing complex operations, Key Flat Shank Shoulder Punches with WPC Treatment and HW Coating are a reliable solution for maintaining position and achieving long-lasting performance. Upgrade your tooling system with these high-performance punches to meet the demands of modern manufacturing.