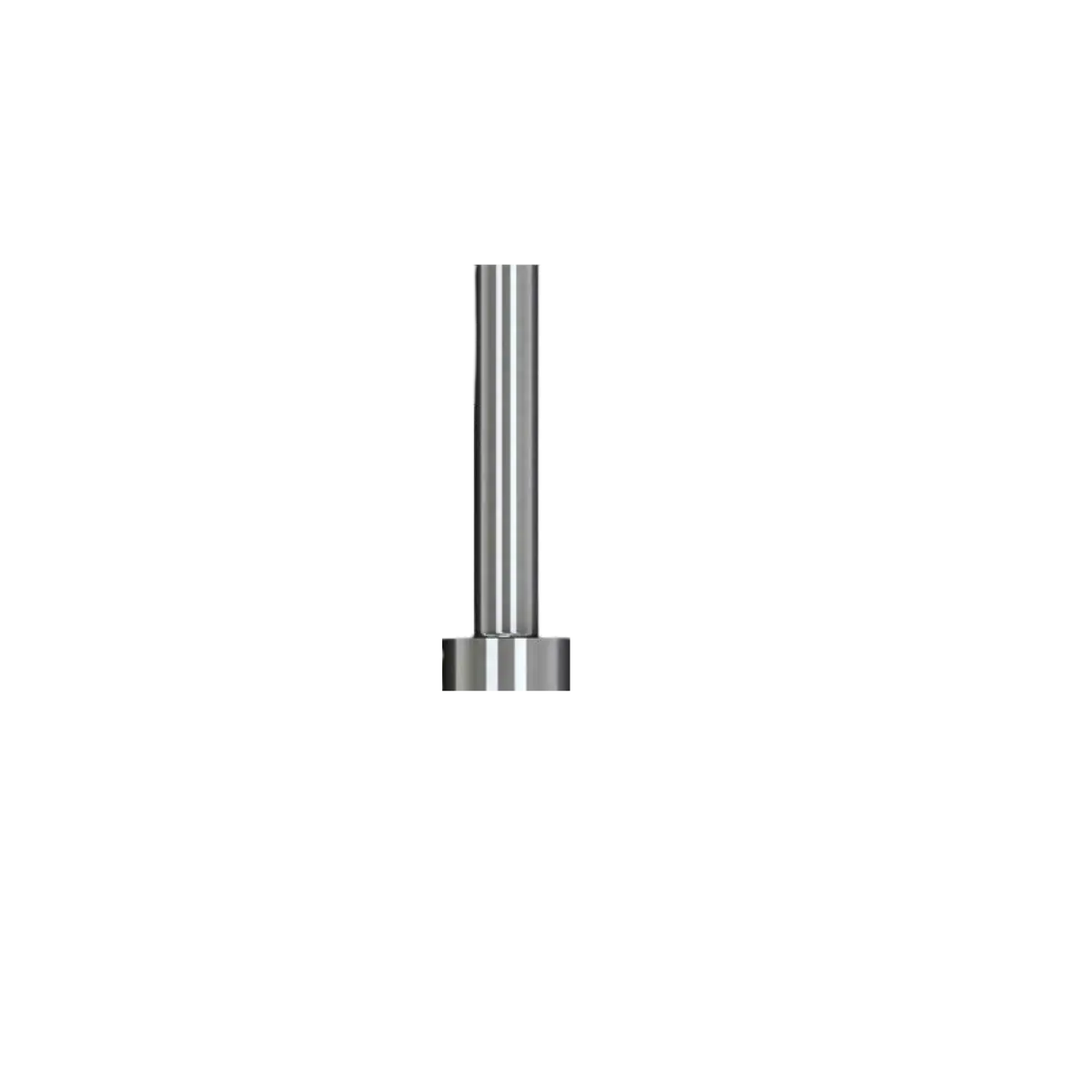

Knockout Pin-DKOP

The Knockout Pin (DKOP) in maintain position press-in die is a durable and reliable tool designed to ensure precision and efficiency in stamping and forming processes. Built to handle rigorous manufacturing demands, this knockout pin stabilizes material positioning within the die, preventing shifts during press operations. It’s engineered with a press-in design that simplifies installation and boosts productivity. Ideal for high-volume applications, DKOP pins reduce downtime by enhancing the alignment and accuracy of each press. Maximize operational consistency and prolong die life with this essential knockout solution.

The Knockout Pin (DKOP) is a critical tool in maintaining precision and efficiency in press-in die operations. Engineered for robust performance, the DKOP knockout pin is designed to remove parts cleanly from dies and molds without causing any damage to the part or mold surface, ensuring smooth ejection and minimizing downtime. With its high-strength construction, the DKOP pin withstands repeated high-pressure use, providing durability in demanding production environments.

Ideal for automotive, metalworking, and industrial applications, the DKOP knockout pin enhances operational stability and productivity. Its precise fit ensures consistent alignment within the die, allowing for controlled, reliable part ejection and reducing the risk of deformation or sticking. Easy to install and replace, the DKOP pin is compatible with various die designs, making it versatile across multiple pressing and forming operations.

Integrating the Knockout Pin (DKOP) into your press-in die setup can lead to improved product quality and a more efficient workflow. Its durability, precision, and seamless operation make it an essential component for anyone looking to maintain exacting standards in high-volume manufacturing processes.