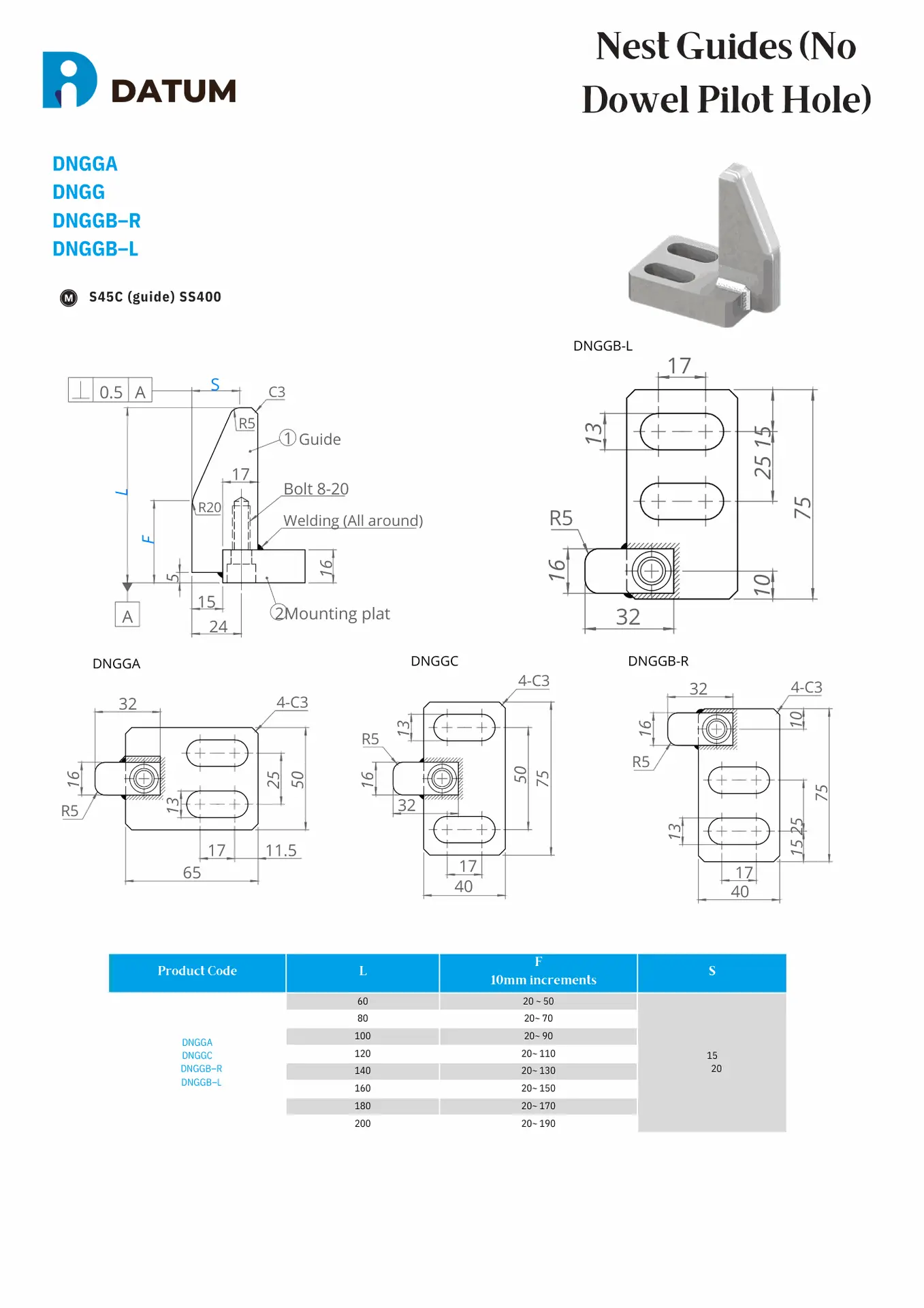

Nest Guides (No Dowel Pilot Hole)-DNGG

Nest Guides (No Dowel Pilot Hole)-DNGG are essential components for ensuring precise alignment in die-press applications. Designed without dowel pilot holes, these guides provide flexibility in installation, making them suitable for a variety of setups. Crafted from high-quality materials, the DNGG model offers exceptional durability and resistance to wear, ensuring reliable performance even in demanding environments. By maintaining the correct position during pressing, these nest guides help minimize misalignment and enhance product quality. Upgrade your die-press system with Nest Guides-DNGG for improved efficiency and long-lasting results.

Nest Guides (No Dowel Pilot Hole)-DNGG are critical components designed for use in die-press applications, where precise alignment is paramount. Unlike traditional guides, the DNGG model features no dowel pilot holes, providing greater flexibility in installation and alignment. This unique design allows for easy adjustments during the setup process, accommodating various configurations without compromising stability.

Constructed from high-quality materials, DNGG Nest Guides ensure exceptional durability, making them ideal for high-volume production environments. Their robust construction not only enhances longevity but also minimizes wear and tear, significantly reducing maintenance costs over time. By maintaining the correct position during pressing, these guides help prevent misalignment, ensuring that every piece produced meets strict quality standards.

Using Nest Guides-DNGG in your die-press operations can lead to improved efficiency and reduced scrap rates. These guides allow for smoother operation, facilitating faster production cycles and enabling manufacturers to meet tight deadlines without sacrificing quality.

In summary, if you're looking to enhance the performance of your die-press system, consider integrating the Nest Guides (No Dowel Pilot Hole)-DNGG into your setup. Experience the benefits of improved alignment, reduced downtime, and superior durability, leading to a more streamlined and effective production process.