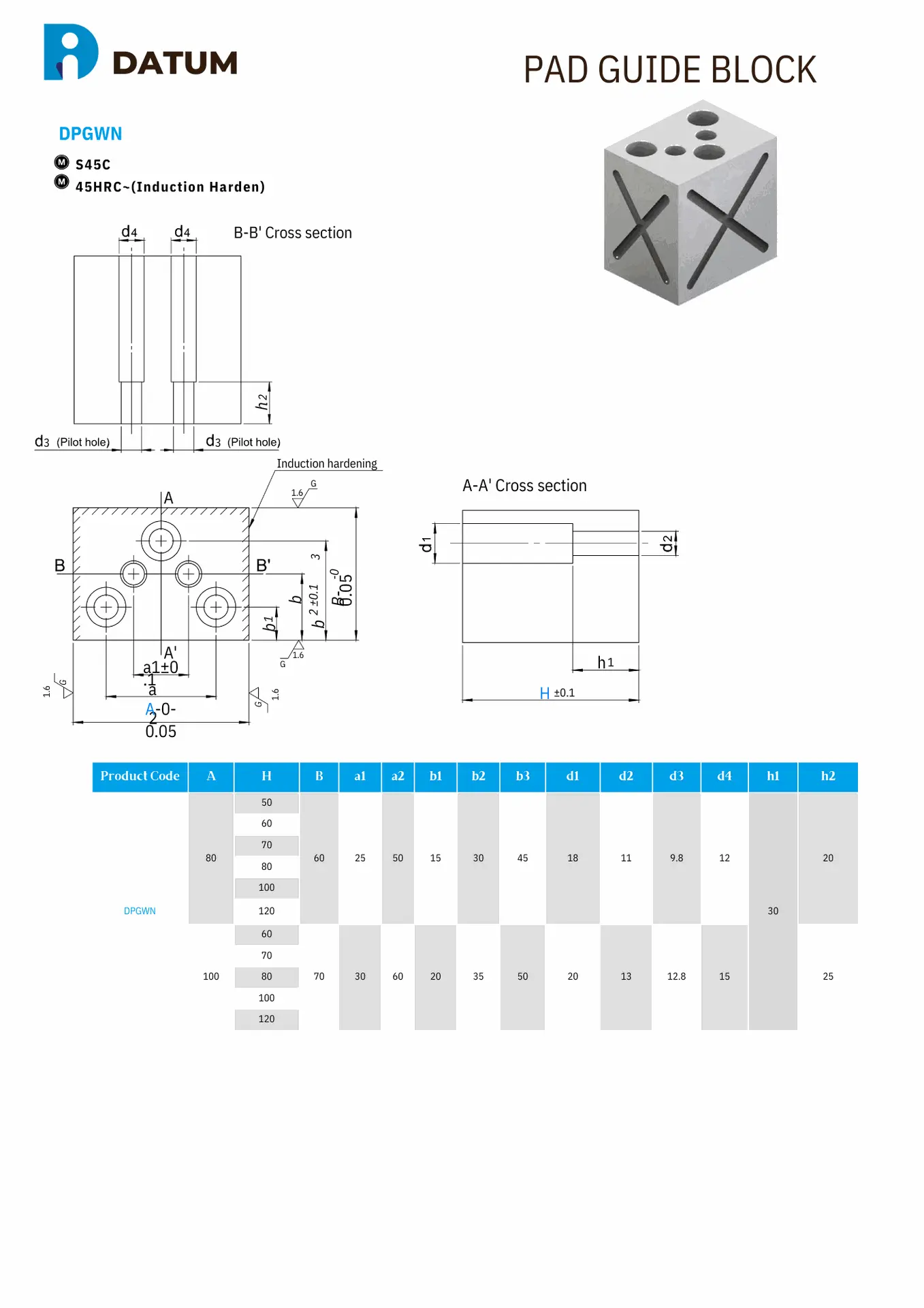

Pad Guide Block-DPGWN

The Pad Guide Block - DPGWN is designed for high-performance die applications, providing stability and precise alignment in maintain-position press setups. Made with durable, wear-resistant materials, this guide block enhances accuracy and reduces friction, ensuring smooth, consistent performance even under heavy loads. Its robust design is ideal for extended operational cycles, minimizing downtime and maintenance requirements. DPGWN’s compatibility with diverse press die systems makes it essential for maintaining die alignment, improving productivity, and supporting longevity in high-demand production environments. Ideal for precision engineering, it ensures reliable positioning and operational

The Pad Guide Block - DPGWN is a highly reliable component designed to enhance stability, precision, and efficiency in maintain-position press die applications. Engineered from high-quality, wear-resistant materials, this guide block minimizes friction and supports smooth operation, even under heavy, repetitive loads, making it ideal for extended production cycles.

The DPGWN guide block is specifically crafted to keep dies aligned accurately, significantly reducing misalignment and promoting consistency in high-demand manufacturing environments. Its robust construction provides exceptional durability, minimizing maintenance needs and lowering long-term operational costs. Due to its compatibility with a range of press die systems, the DPGWN guide block is versatile and easily integrated, ensuring consistent performance across different setups.

By improving stability and alignment within the press, the DPGWN reduces wear on surrounding components, extending the lifespan of both the guide block and the overall die assembly. This reliability makes it indispensable for manufacturers who require precise die positioning and uninterrupted production flow. Ideal for heavy-duty operations and precision engineering, the DPGWN Pad Guide Block delivers substantial efficiency gains, supporting a smooth and reliable workflow for large-scale production needs.