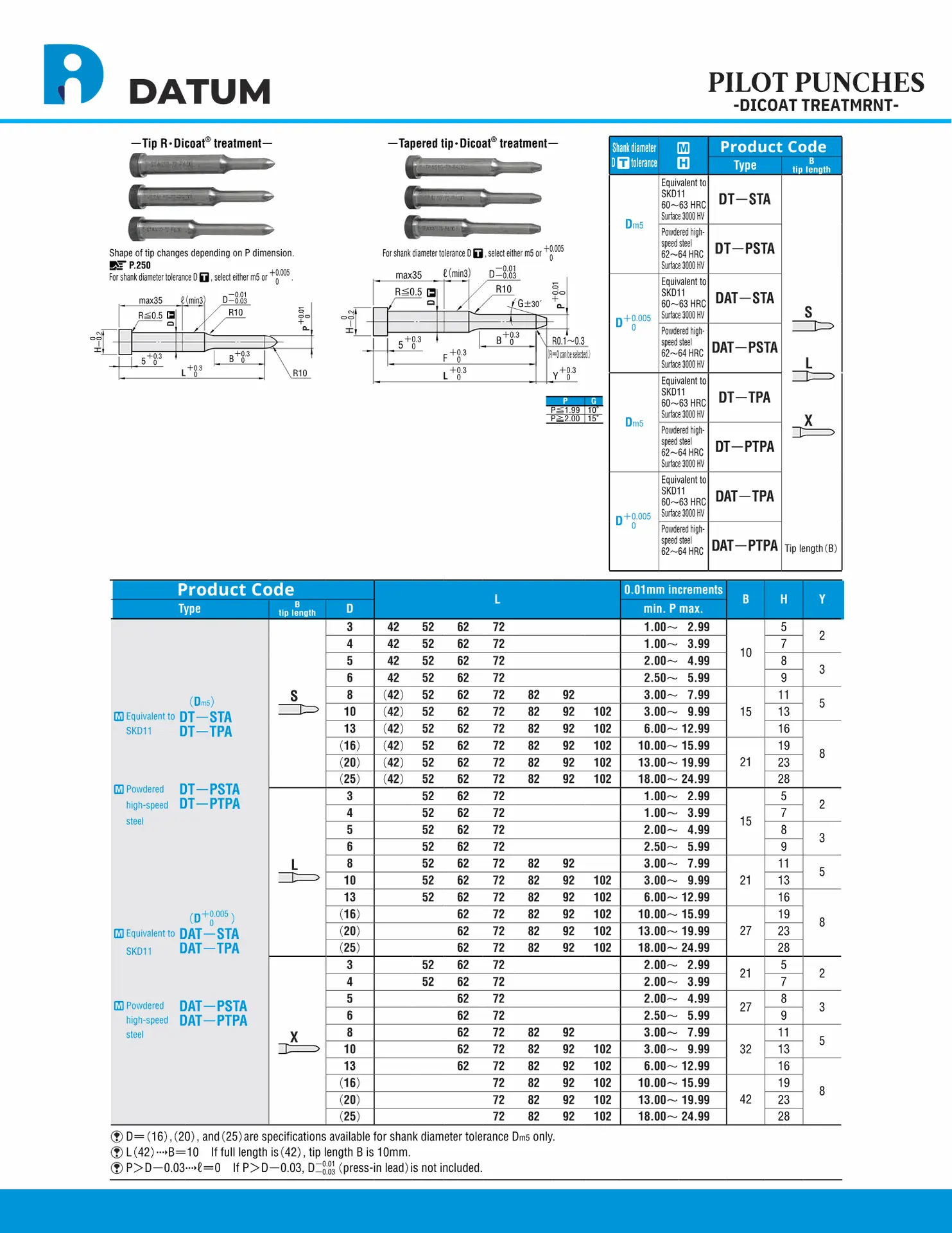

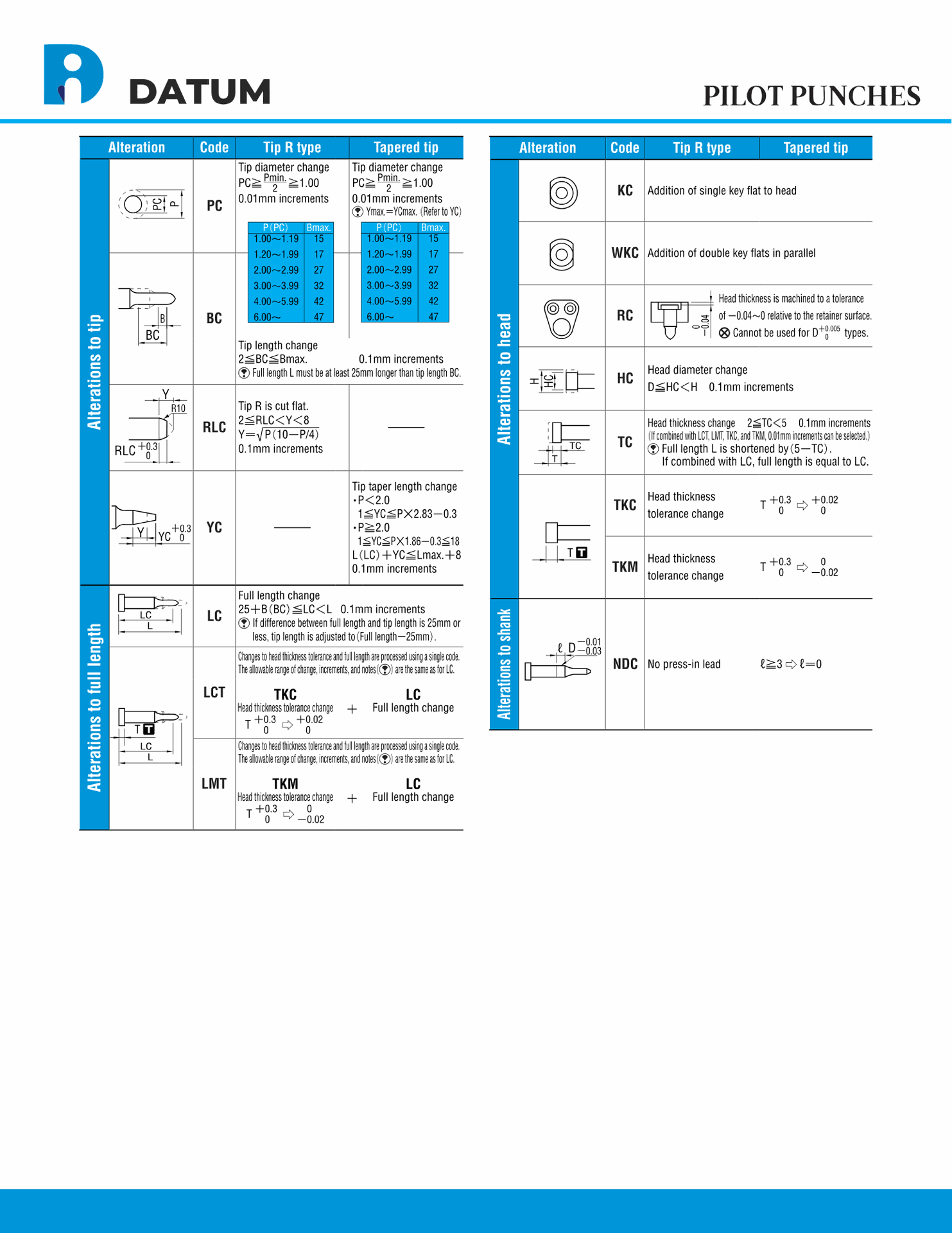

PILOT PUNCHES

Dicoat Treatment

Pilot punches with Dicoat treatment are ideal for maintain position press-in-die applications, offering superior performance and durability. Dicoat treatment enhances the punch's resistance to wear, corrosion, and friction, ensuring a longer tool life even under heavy-load conditions. This advanced coating technology provides a smooth cutting surface, reducing the need for frequent maintenance and downtime. Perfect for industries requiring high-precision punching, such as automotive and manufacturing, Dicoat-treated pilot punches maintain sharpness, ensuring consistent, reliable results for efficient production. Optimize your die-cutting operations with these high-performance punches.

Pilot punches with Dicoat treatment are engineered to provide exceptional durability and performance in maintain position press-in-die applications. Dicoat, a cutting-edge coating technology, significantly enhances the punch's resistance to wear, corrosion, and friction. This protective layer ensures that pilot punches maintain their sharpness and functionality even under the most demanding conditions.

The Dicoat treatment reduces tool wear and tear, leading to longer tool life and reduced maintenance costs, ultimately increasing production efficiency. With a smooth and precise cutting surface, Dicoat-treated pilot punches deliver consistent results, making them ideal for industries such as automotive, manufacturing, and metalworking, where precision and reliability are crucial.

These punches are specially designed to withstand the heavy loads and pressures of die-cutting operations, reducing downtime and the need for frequent tool replacements. By incorporating Dicoat treatment, these pilot punches ensure optimum performance over time, even in high-volume production environments.

If you're seeking a long-lasting, efficient solution for your pressing and punching needs, Dicoat-treated pilot punches offer the perfect balance of durability, precision, and cost-effectiveness. Choose Dicoat for your next die-cutting project and experience enhanced tool performance that translates into increased operational efficiency and reduced maintenance costs.