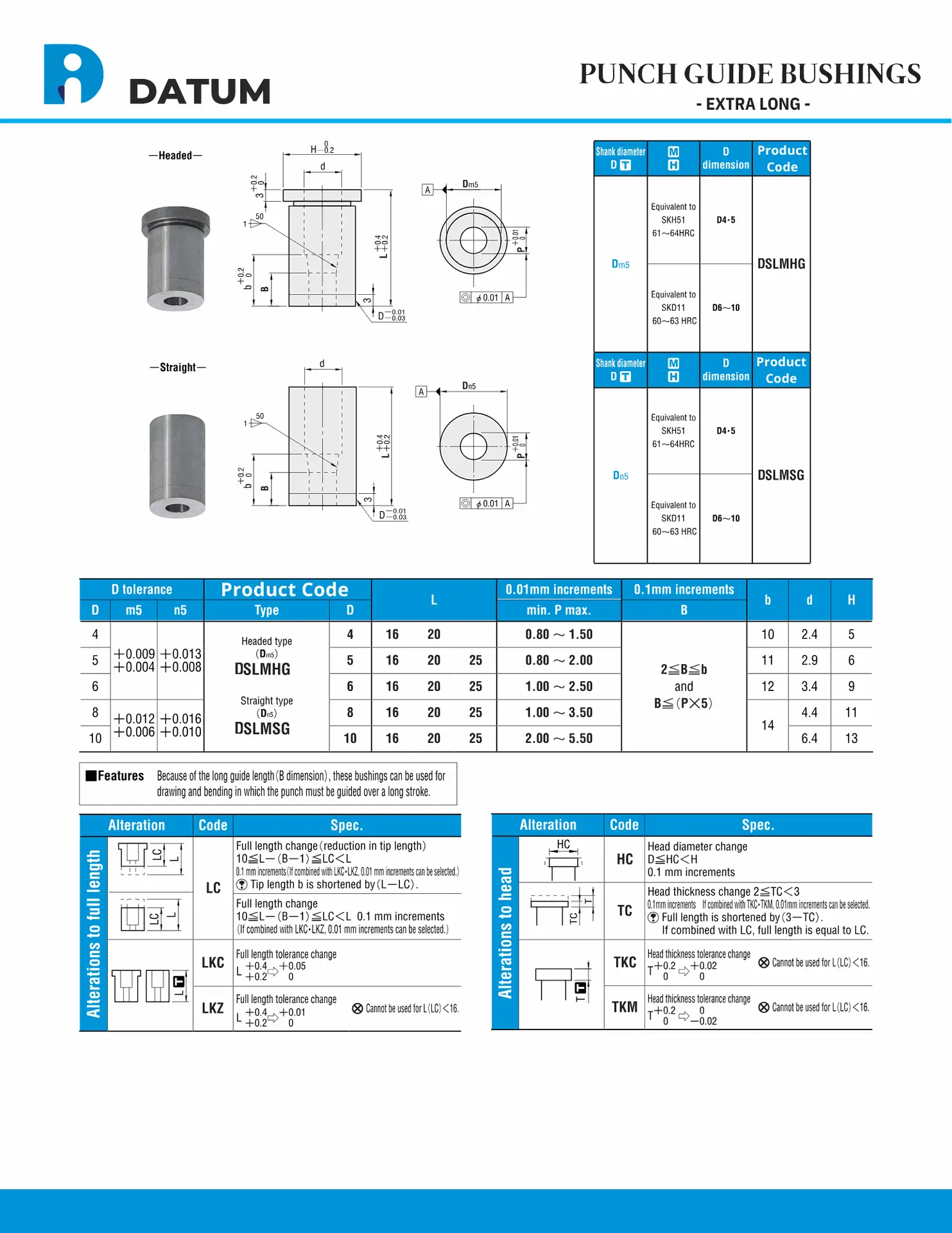

PUNCH GUIDE BUSHINGS

Extra long

Extra long punch guide bushings are designed to provide superior stability and precision in maintain position press dies. Their extended length ensures optimal alignment and smooth punch movement, reducing misalignment during high-speed, high-pressure stamping operations. Built for durability, these bushings minimize friction and wear, extending tool life and reducing maintenance costs. Ideal for industries like automotive, aerospace, and electronics, extra long punch guide bushings enhance stamping accuracy, ensuring consistent, high-quality results while optimizing overall production efficiency and reducing downtime.

Extra long punch guide bushings are designed to provide enhanced stability and precision in maintain position press dies, ensuring optimal punch alignment and performance during the stamping process. The extended length of these guide bushings is ideal for applications that require greater control and accuracy, particularly in high-speed and high-pressure environments. Their design helps reduce misalignment, ensuring smooth and consistent punch movement, which improves the overall quality of the stamped components.

Built for durability, extra long punch guide bushings are engineered to withstand the demands of rigorous stamping operations. They significantly reduce friction and wear on both the punch and die, extending the tool life and minimizing the need for frequent maintenance. By providing superior stability, these bushings help maintain tight tolerances, leading to better stamping results with fewer errors.

Ideal for industries such as automotive, aerospace, and electronics, extra long punch guide bushings contribute to improved productivity and efficiency. They optimize stamping operations by reducing downtime and enhancing the reliability of production.

Investing in extra long punch guide bushings helps manufacturers achieve high-quality, consistent results while minimizing operational costs. These bushings ensure smoother, more reliable stamping processes, improving overall production efficiency and delivering superior outcomes in metalworking operations.