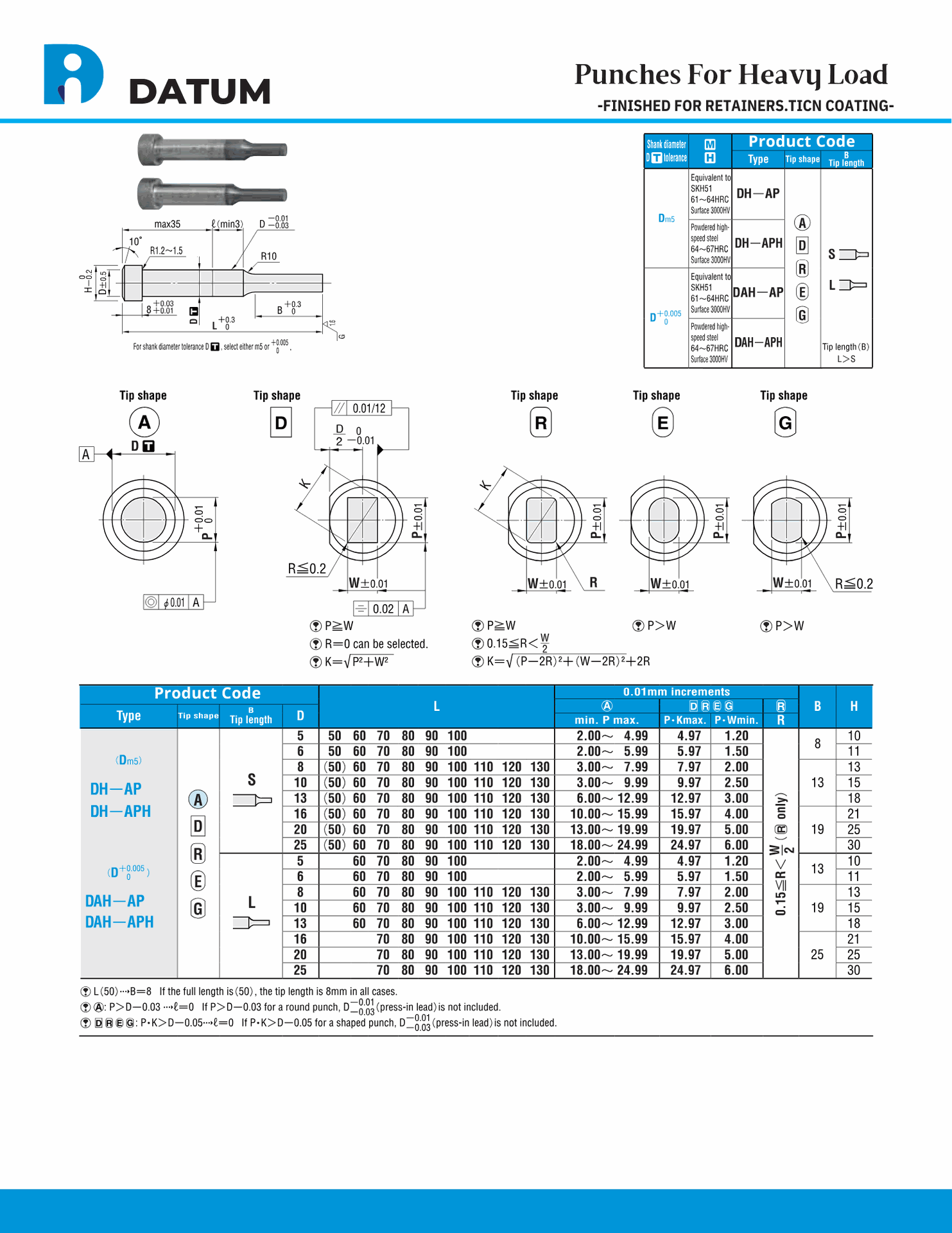

Punches For Heavy Load

Finished For Retainers Ticn Coating

Punches for heavy load, finished for retainers with TiCN coating, are designed for high-performance press-in-die applications. The TiCN (Titanium Carbon Nitride) coating significantly enhances the punch’s hardness, wear resistance, and overall durability. This protective coating reduces friction, prolonging tool life even in the most demanding environments. Ideal for heavy-duty industries such as automotive and manufacturing, these punches ensure precise positioning, improved efficiency, and reduced maintenance costs. TiCN-coated punches are perfect for high-load and high-precision tasks, providing excellent performance in every use.

Punches for heavy load, finished for retainers with TiCN (Titanium Carbon Nitride) coating, are engineered for demanding press-in-die applications where durability and precision are crucial. The TiCN coating enhances the punch's hardness, wear resistance, and reduces friction, ensuring optimal performance in high-load and high-stress environments. Designed for heavy-duty industries such as automotive, metalworking, and manufacturing, these punches are ideal for tasks requiring precise positioning and extended tool life.

The TiCN coating offers superior protection against wear, corrosion, and abrasion, extending the lifespan of the punches and reducing the frequency of replacements. This makes them a cost-effective solution for high-volume operations. By minimizing friction, the coating improves cutting efficiency, reducing the risk of material damage and providing consistent, smooth operations.

Whether used for heavy-duty presses or intricate die work, these punches are designed to maintain their integrity under extreme conditions. Their precision and longevity make them a reliable choice for professionals seeking efficient and dependable tools. With TiCN coating, punches for heavy load are the perfect solution for maintaining the integrity of your press-in-die systems, enhancing productivity while lowering operational costs.