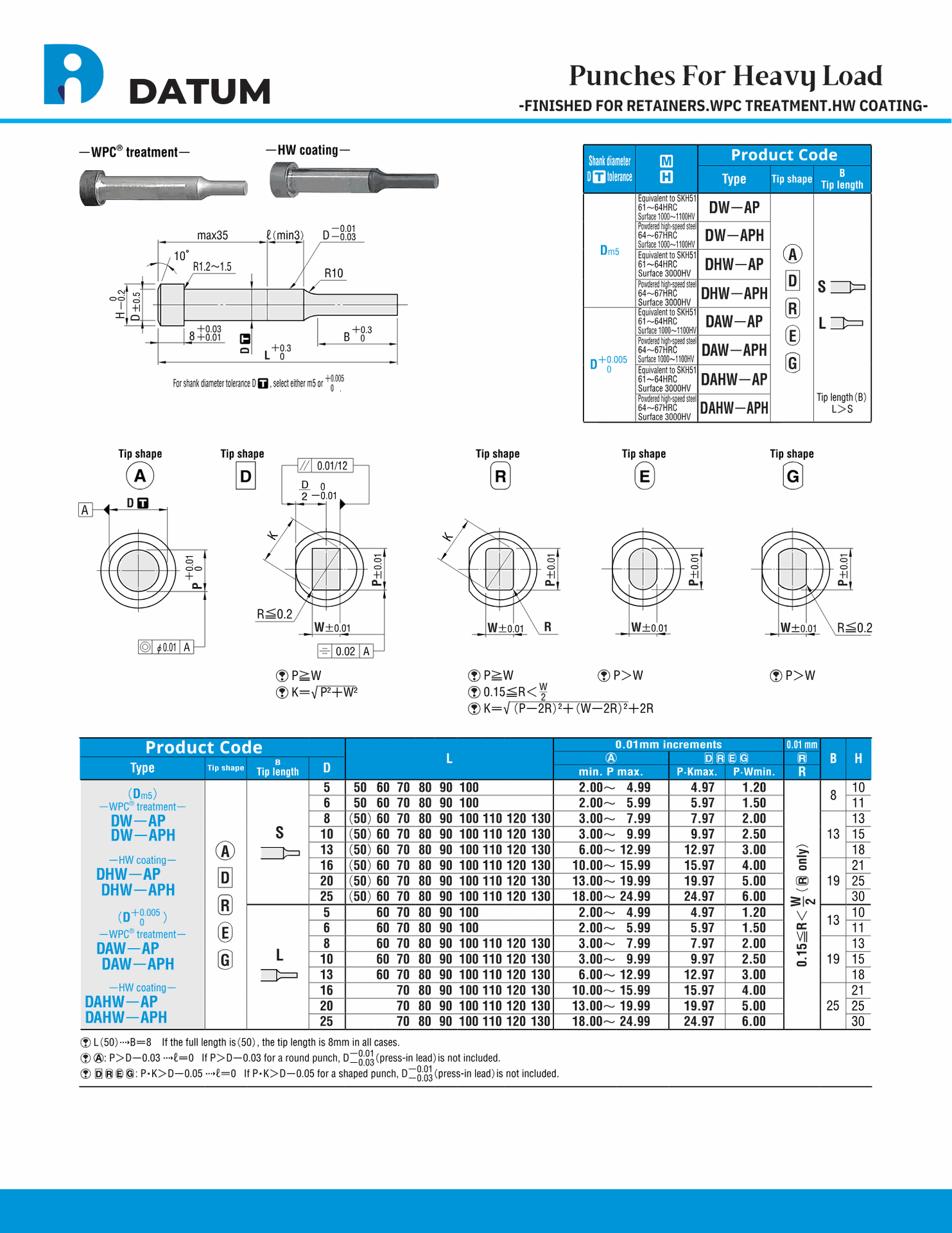

Punches For Heavy Load

Finished For Retainers WPC Treatment HW Coating

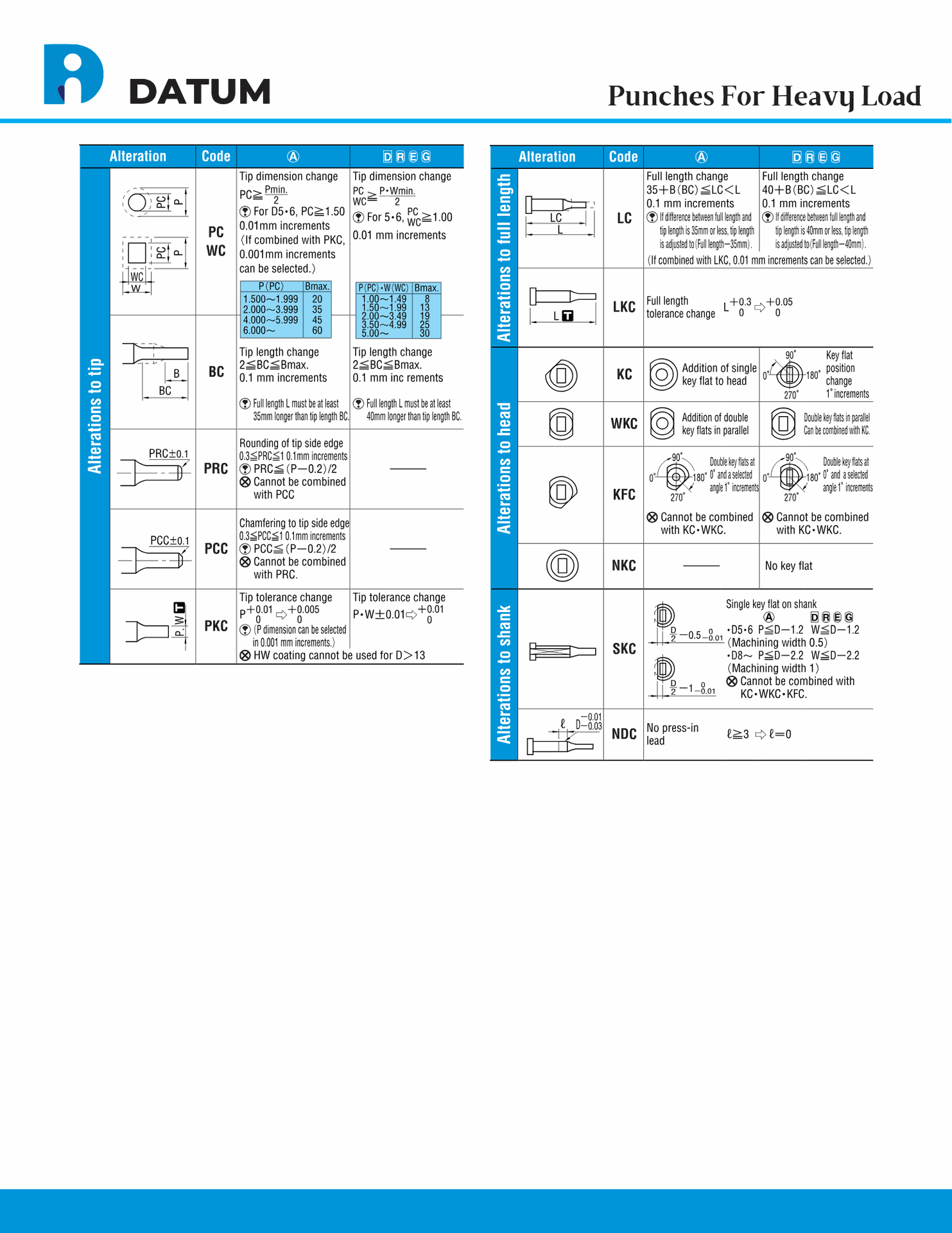

Punches for heavy load, finished for retainers with WPC (Wire-Arc Plasma Coating) treatment and HW (High Wear) coating, offer enhanced durability and superior performance in high-stress press-in-die applications. The WPC treatment and HW coating provide exceptional resistance to wear, corrosion, and abrasion, ensuring longer tool life and reliable performance. These punches are ideal for demanding industries, where precision and resilience are essential. With improved resistance to heavy loads, they minimize downtime, enhance productivity, and deliver consistent results in tough operating conditions.

Punches for heavy loads, finished for retainers with WPC (Wire-Arc Plasma Coating) treatment and HW (High Wear) coating, are designed for optimal performance in press-in-die applications. These specialized punches offer exceptional durability, ensuring they withstand the toughest manufacturing environments and high-stress operations. The WPC treatment significantly enhances wear resistance, while the HW coating provides superior protection against abrasion and corrosion. This combination ensures extended tool life, reduced maintenance, and improved efficiency.

These heavy-duty punches are ideal for industries that require precision and reliability under extreme conditions. Whether you're dealing with high-volume production or challenging materials, these punches maintain their integrity throughout long runs, reducing downtime and ensuring consistent, high-quality results.

By incorporating WPC treatment and HW coating, these punches deliver exceptional resistance to heavy loads, ensuring your equipment performs at peak efficiency. This added protection also contributes to overall cost savings, as they help avoid frequent tool replacements. The durable nature of these punches guarantees they can withstand even the harshest conditions, making them the preferred choice for professionals seeking longevity and reliable performance in demanding press-in-die applications.