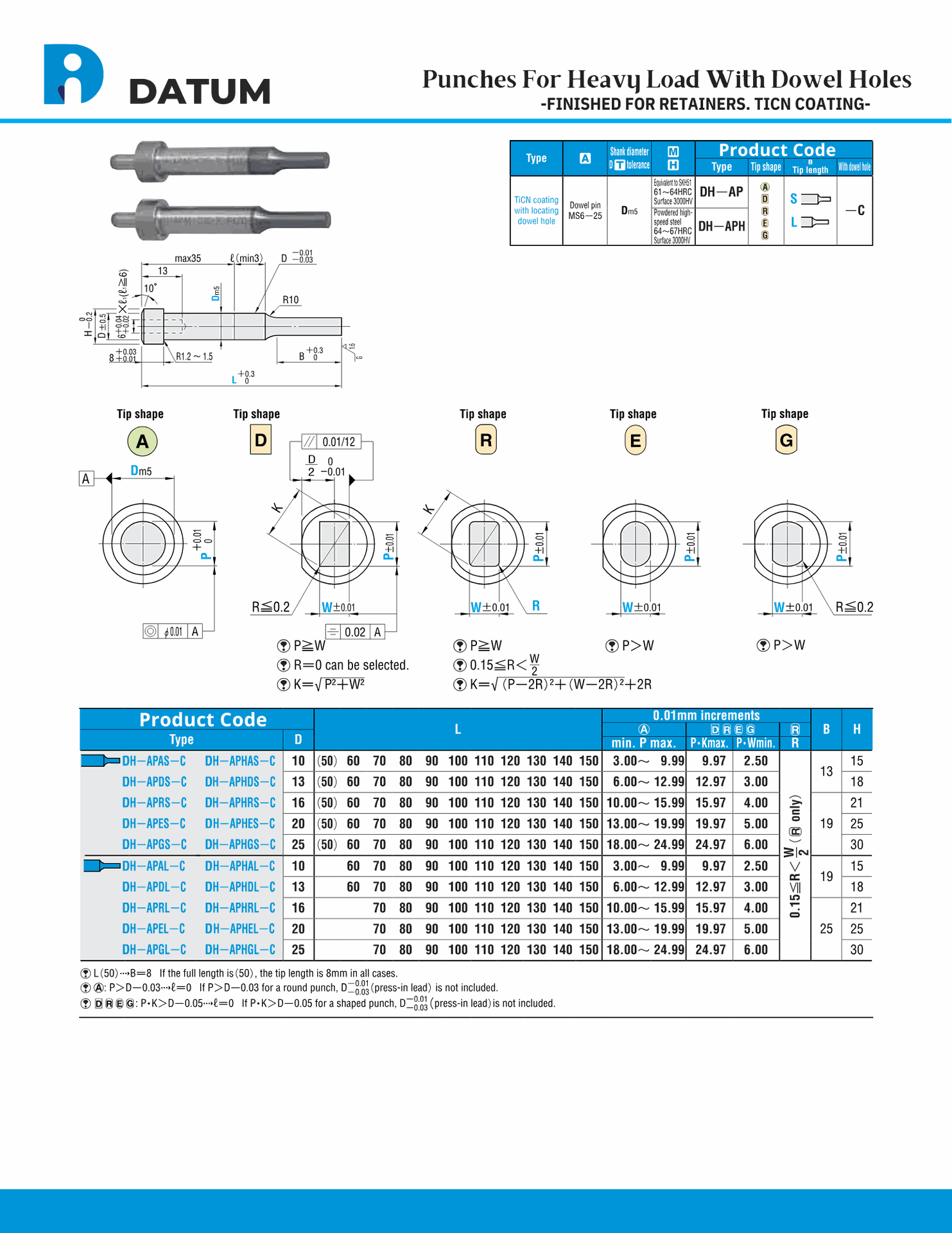

Punches For Heavy Load With Dowel Holes

Finished For Retainers Ticn Coating

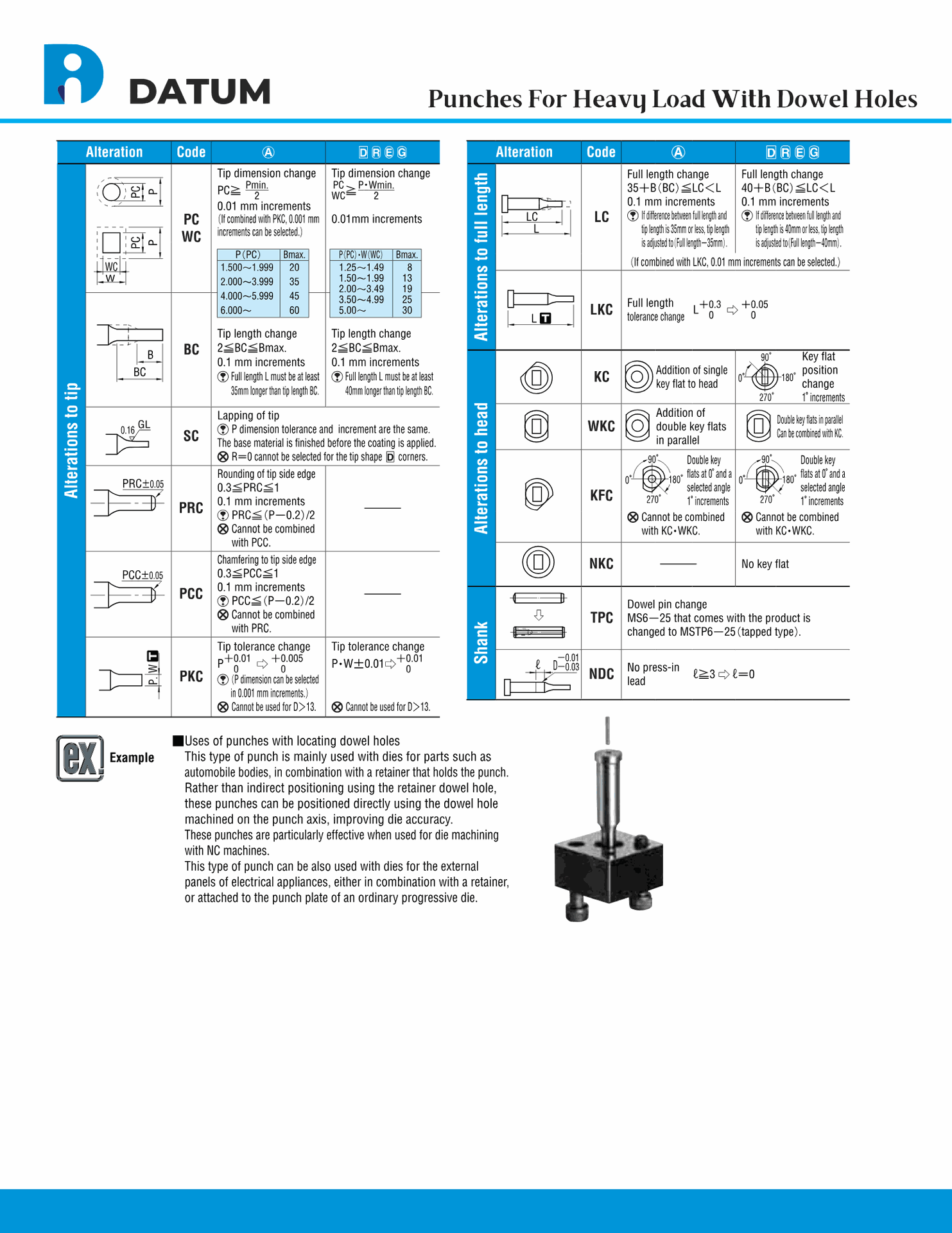

Punches for Heavy Load with Dowel Holes, Finished for Retainers with TiCN Coating, provide exceptional durability and precision for press-in-die applications. Engineered to handle heavy loads, these punches feature dowel holes for accurate alignment and secure positioning, ensuring consistent performance in high-strength material processing.The TiCN coating enhances wear resistance, reducing friction and extending tool life, even under intense operational conditions. Ideal for maintaining position and delivering reliable results, these punches are a trusted choice for industries demanding superior performance and longevity.

Punches for Heavy Load with Dowel Holes, Finished for Retainers with TiCN Coating, are engineered for precision, durability, and superior performance in demanding press-in-die applications. Designed to handle heavy loads with ease, these punches feature dowel holes that ensure accurate alignment and secure positioning, enhancing operational efficiency and maintaining stability during high-stress operations.

The TiCN (Titanium Carbonitride) coating further elevates the performance of these punches by providing exceptional hardness and wear resistance. This advanced coating reduces friction, minimizes wear, and extends the tool's lifespan, even under rigorous conditions. The result is consistent performance, reduced downtime, and enhanced productivity in manufacturing processes.

These punches are ideal for applications requiring precision and strength, such as forming, stamping, or cutting in industries that work with high-strength materials. The finished retainers provide a secure fit, ensuring optimal functionality and reliability.

Whether used in automotive, aerospace, or industrial manufacturing, these heavy-load punches with TiCN coating are the go-to solution for maintaining position, reducing operational costs, and achieving consistent results in press-in-die operations. Invest in these advanced tools to boost efficiency and meet the demands of modern manufacturing.