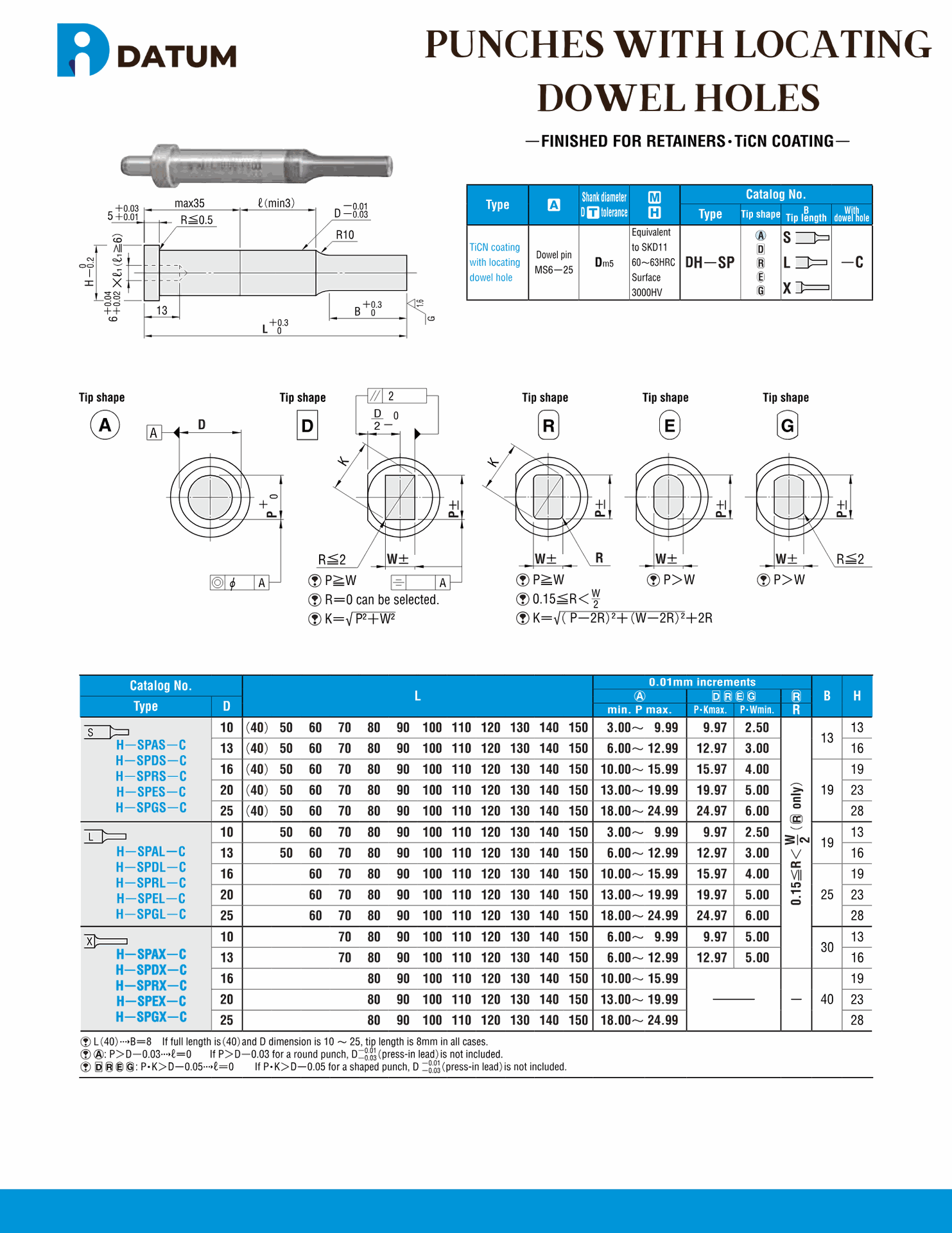

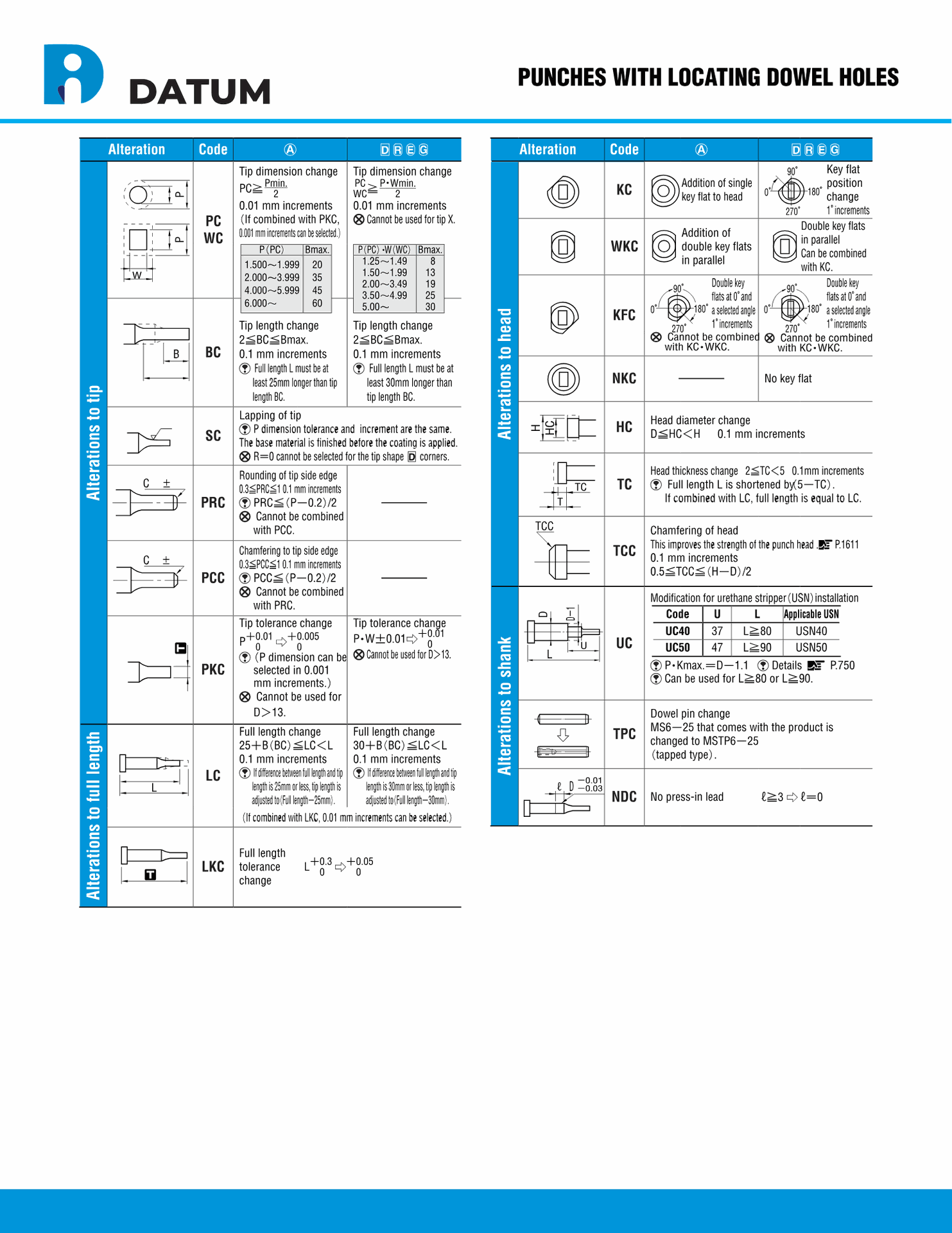

Punches With Locating Dowel Holes

Finished For Retainers Ticn Coating- DH-SPAS-C

DH-SPAS-C punches with locating dowel holes, finished for retainers and coated with TiCN, are engineered for high-performance tools manufacturing. These precision punches offer excellent wear resistance, superior hardness, and reliable alignment thanks to integrated dowel holes. The TiCN coating enhances durability, reduces friction, and extends tool life in demanding operations. Ideal for dies and stamping applications, DH-SPAS-C punches ensure consistent accuracy and performance, making them essential components in high-precision manufacturing environments like automotive, aerospace, and industrial tooling.

DH-SPAS-C Punches with Locating Dowel Holes, finished for retainers and coated with advanced TiCN (Titanium Carbo-Nitride), are premium-grade components designed for precision tools manufacturing. These punches feature accurately machined dowel holes for perfect alignment and positioning, ensuring stable and repeatable operations in high-speed stamping and die applications. The TiCN coating provides exceptional surface hardness, increased wear resistance, and reduced friction, significantly extending tool life and maintaining dimensional accuracy over long production cycles.

Ideal for use in automotive, aerospace, and general industrial tooling systems, DH-SPAS-C punches enhance performance, reduce maintenance, and ensure consistent output quality. Their robust construction and corrosion resistance make them reliable in challenging environments, while the finished surfaces ensure compatibility with a wide range of retainers.

By integrating DH-SPAS-C punches into your tooling setup, manufacturers can achieve superior precision, operational efficiency, and long-term cost savings. These punches are a critical component for maintaining excellence in modern manufacturing workflows.