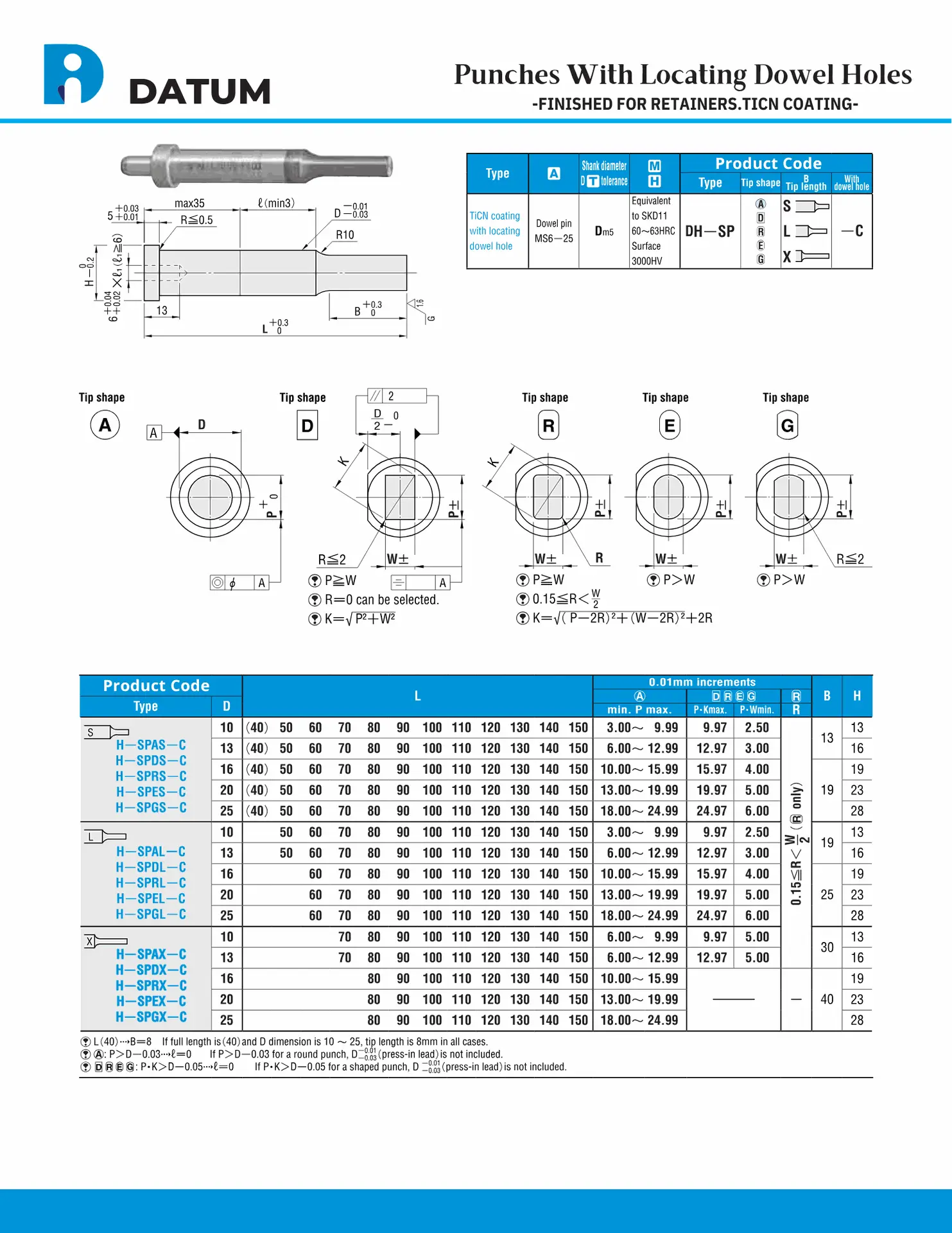

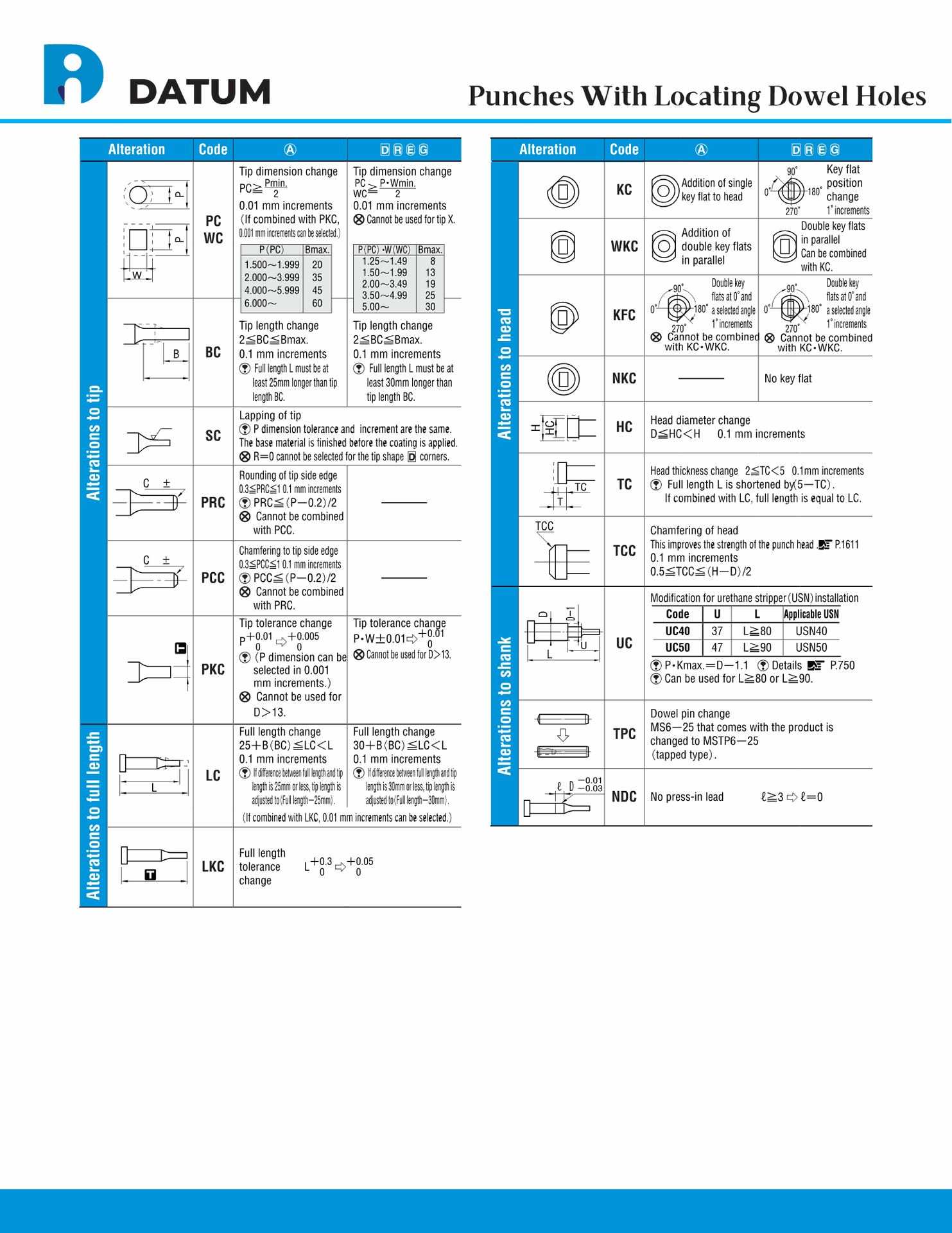

Punches With Locating Dowel Holes

Finished For Retainers Ticn Coating

Punches with locating dowel holes, finished for retainers, and coated with TiCN (Titanium Carbonitride) are essential for precision die operations. The TiCN coating enhances the durability and hardness of the punch, offering superior resistance to wear, friction, and corrosion. This coating ensures longevity, reducing the frequency of tool replacements and increasing efficiency. Designed for use in maintain position press dies, these punches provide accurate alignment and consistent performance, making them ideal for high-precision stamping and punching applications in various industries.

Punches with locating dowel holes, finished for retainers, and coated with TiCN (Titanium Carbonitride) offer exceptional performance and durability in maintain position press die operations. The TiCN coating, known for its high hardness and wear resistance, significantly improves the punch's lifespan, making it ideal for high-volume and precision stamping applications. By providing superior resistance to friction, corrosion, and heat, TiCN ensures consistent, high-quality results even under extreme working conditions.

Designed specifically for use with retainers, these punches offer precise alignment, ensuring that the tool remains securely in place throughout the process. The locating dowel holes help with accurate positioning, improving the overall efficiency and accuracy of your stamping and punching tasks. Whether you’re working in automotive manufacturing, electronics, or metalworking industries, these punches guarantee optimal performance.

With a focus on longevity, reduced downtime, and increased productivity, punches with TiCN coating for retainers provide a reliable solution for businesses looking to enhance their die-cutting processes. Offering an ideal balance of performance, cost-effectiveness, and durability, these punches will optimize your press die operations, reducing the need for frequent tool changes while ensuring precision in every punch.