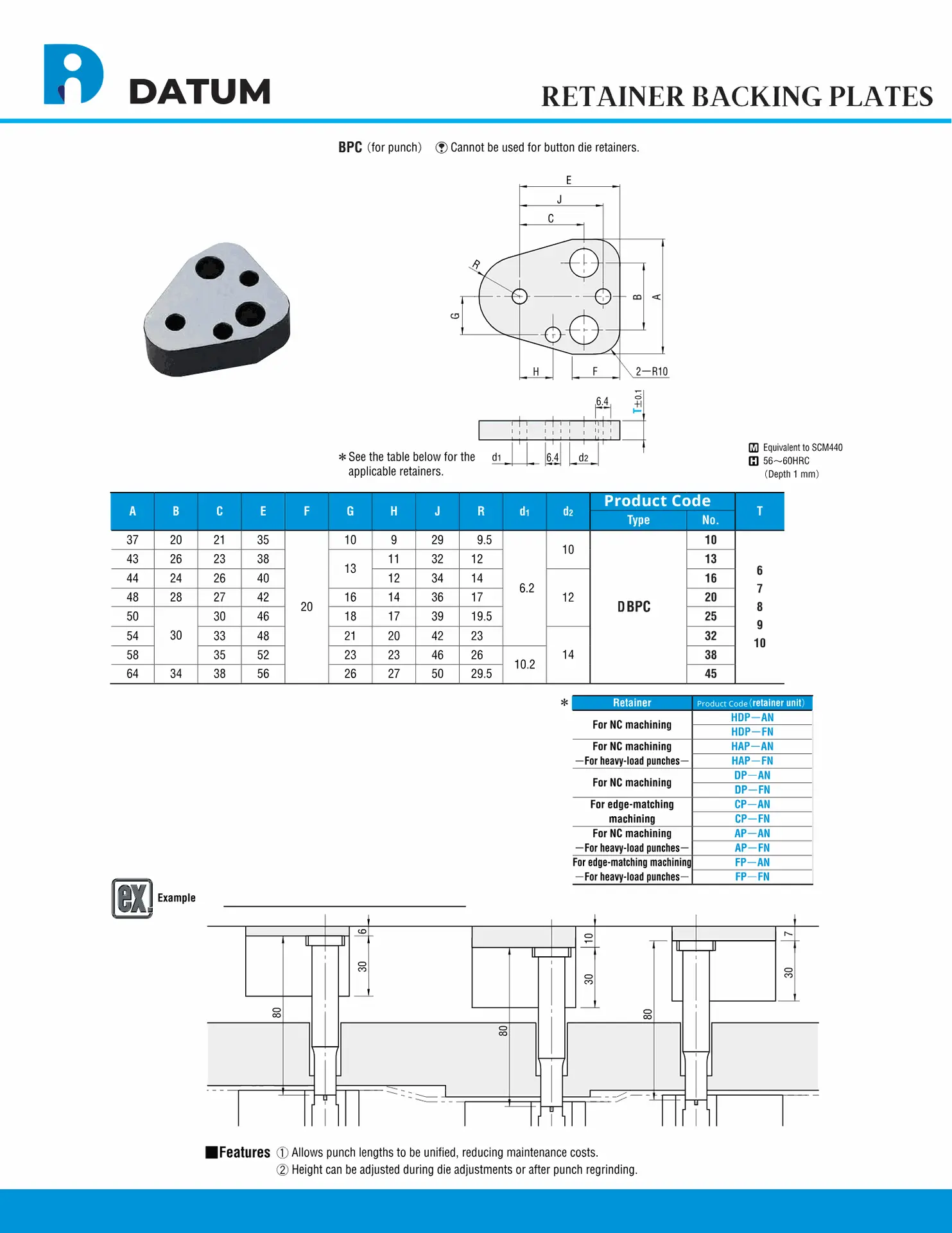

RETAINER BACKING PLATES

Retainer backing plates are critical components used in maintain position press dies, ensuring proper alignment and stability during manufacturing processes. These plates provide a secure base for retainers, minimizing wear and tear on the die while improving precision and efficiency. Manufactured from durable, high-quality materials, retainer backing plates enhance die performance, extend tool life, and reduce maintenance costs. Ideal for industries such as automotive and aerospace, these plates ensure consistent, reliable results in high-volume production environments.

Retainer backing plates are essential components used in maintain position press dies, ensuring the stability and proper alignment of the die during various industrial processes. These plates play a critical role in supporting the retainers, preventing unnecessary movement or misalignment, and minimizing wear and tear on other die components. Their precision and durability contribute to the overall efficiency of the manufacturing process.

Manufactured from high-quality, wear-resistant materials, retainer backing plates are designed to withstand the pressures of high-volume production environments, ensuring long-lasting performance. By maintaining the correct position and alignment of the retainers, these backing plates enhance the accuracy and consistency of the produced parts, leading to better product quality and fewer errors.

Retainer backing plates also help reduce maintenance costs by extending the lifespan of the die and minimizing downtime due to misalignment issues. This makes them a cost-effective solution for industries such as automotive, aerospace, and manufacturing.

By providing reliable support and maintaining proper positioning throughout the die operation, retainer backing plates play a crucial role in improving productivity and reducing operational costs. These plates are vital for ensuring that your die setup remains efficient and effective, delivering high-quality results with every press cycle.