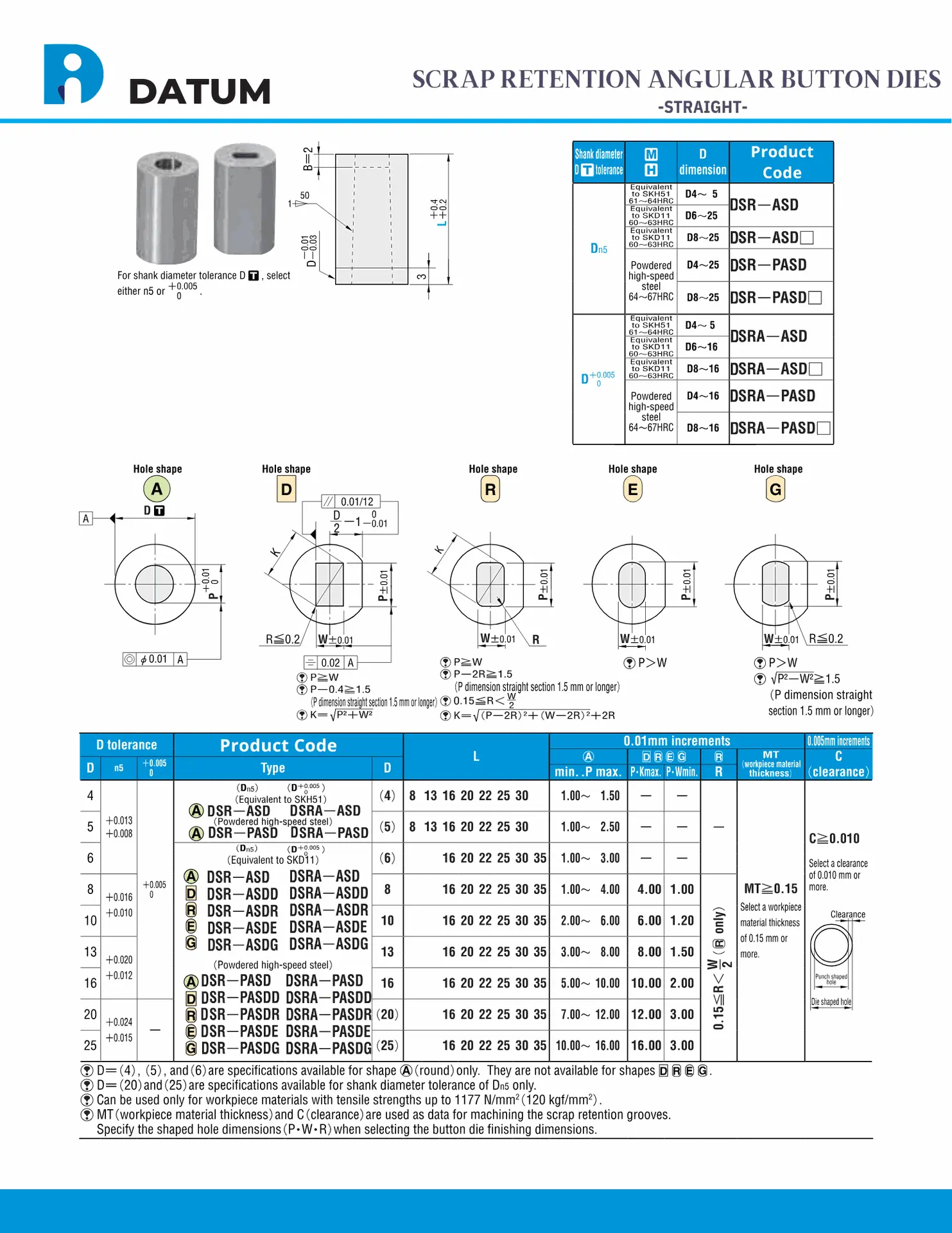

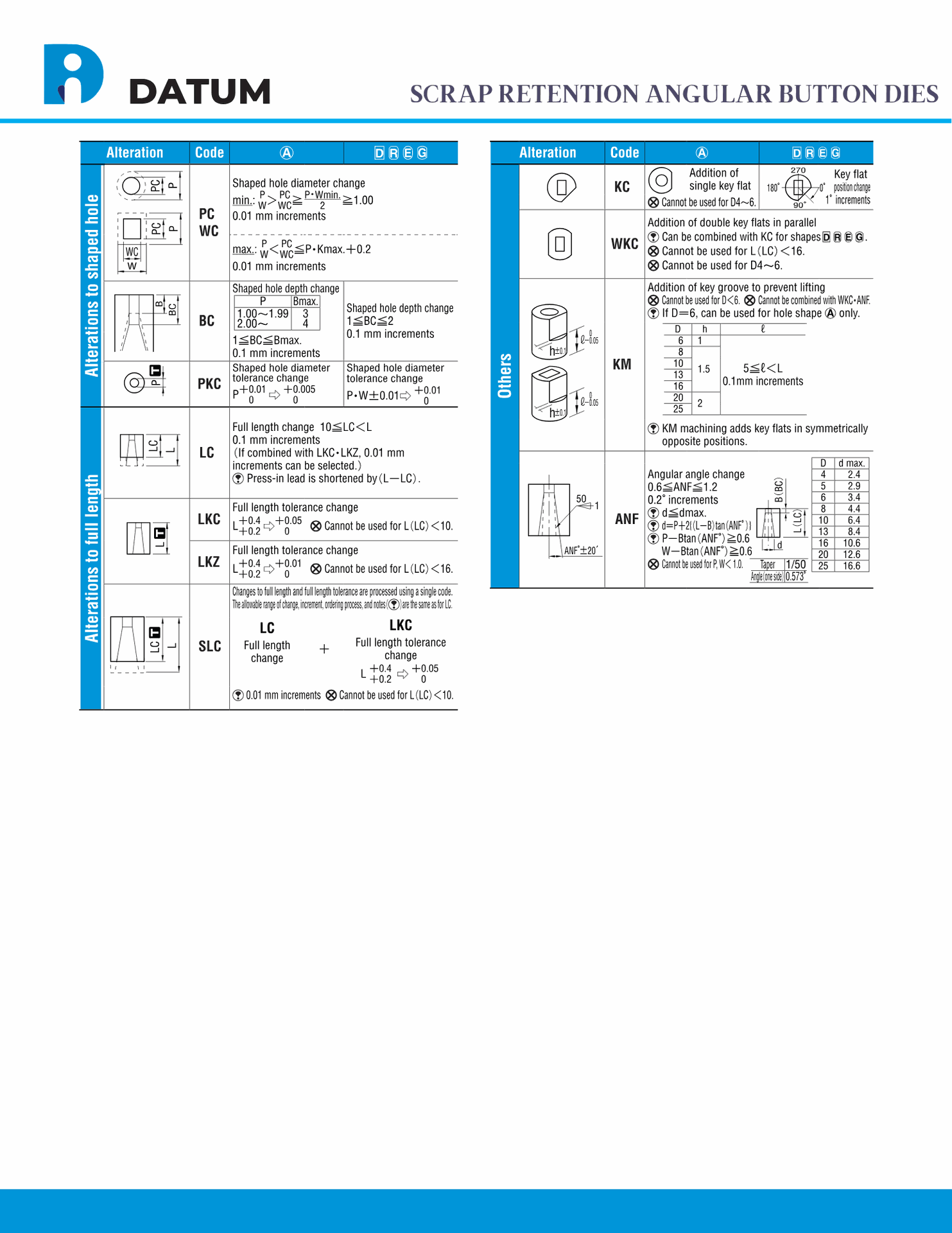

SCRAP RETENTION ANGULAR BUTTON DIES

(Straight)

Scrap retention angular button dies (straight) are precision-engineered tools designed for efficient scrap management in maintain position press dies. The straight configuration ensures reliable alignment and stability, making them ideal for high-speed stamping operations. These dies handle angular cuts with accuracy while securely retaining scrap material, reducing waste and preventing interference. Built from durable materials, they perform consistently under high-pressure conditions. Perfect for industries like automotive and electronics, these dies optimize production efficiency and ensure high-quality output in metal stamping processes.

Scrap retention angular button dies (straight) are critical components in metal stamping processes, designed to provide precision, stability, and efficiency in maintain position press dies. With a straight configuration, these dies ensure accurate alignment and reliable performance, even in high-speed and high-pressure stamping operations. Their design is ideal for executing angular cuts with superior accuracy, meeting the rigorous demands of industries such as automotive, aerospace, and electronics.

One of the standout features of these dies is their efficient scrap retention capability. By securely holding scrap material, they help maintain a clean production environment, reducing interference during stamping operations and improving workflow efficiency. This functionality minimizes material waste and contributes to overall cost savings.

Manufactured from robust, wear-resistant materials, straight angular button dies are built to withstand the demanding conditions of modern manufacturing. Their durability ensures long-lasting performance, reducing downtime and the need for frequent replacements. These dies enhance production efficiency while ensuring consistent, high-quality output.

For manufacturers seeking to improve precision, streamline production, and reduce costs, scrap retention angular button dies (straight) offer an excellent solution. They combine reliability, durability, and precision to optimize performance in metal stamping applications.