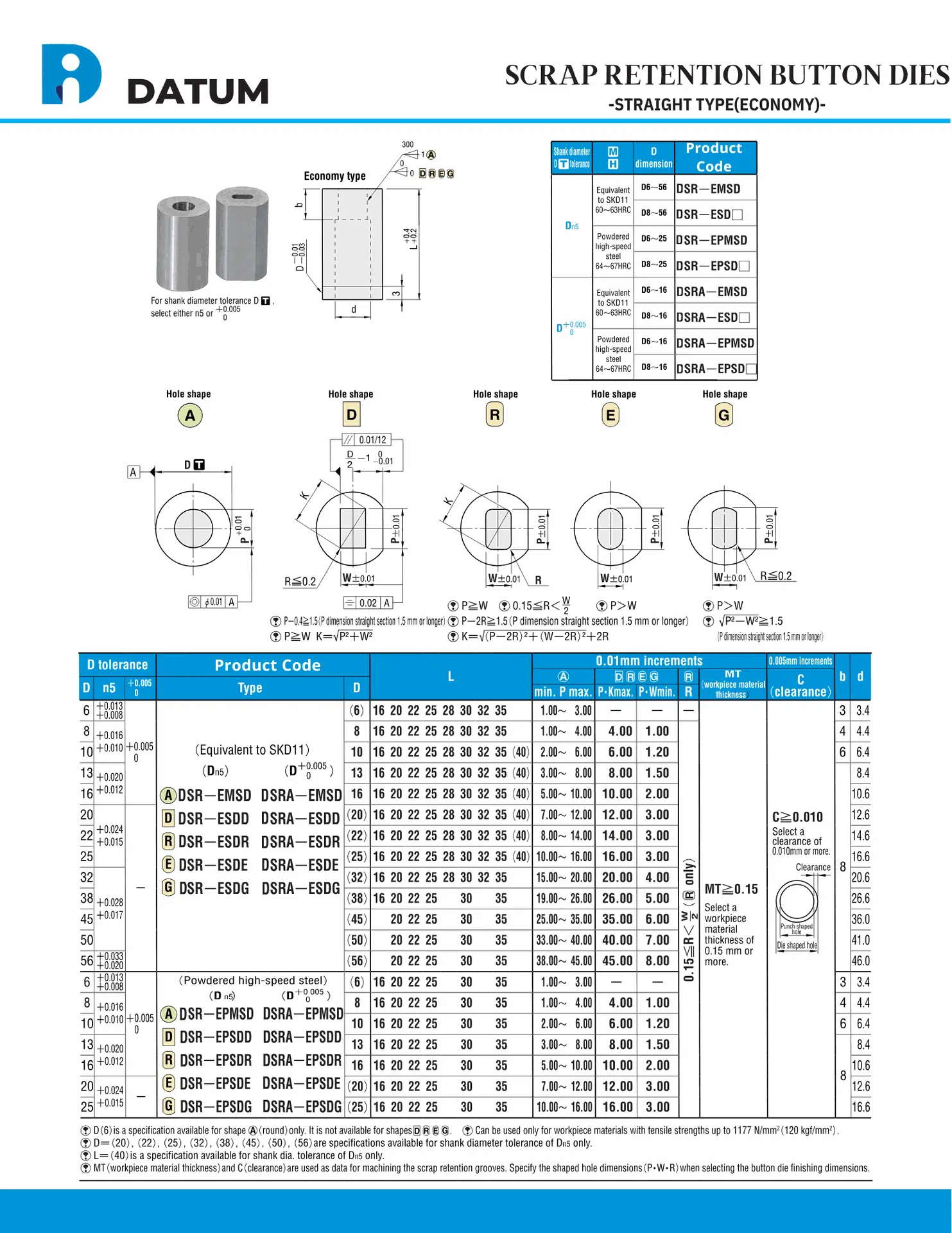

SCRAP RETENTION BUTTON DIES

-Straight Type (Economy)-

Straight type economy scrap retention button dies are a cost-effective solution for efficient scrap management in maintain position press dies. These dies ensure proper alignment and securely retain scrap material during stamping, reducing interference and downtime. Designed for durability, they perform reliably in high-speed, high-pressure applications across industries like automotive and electronics. Their economical design delivers excellent performance without compromising quality, making them ideal for optimizing production efficiency, reducing scrap rates, and ensuring consistent, high-quality results in metal stamping processes.

Scrap retention button dies (straight type, economy) offer a cost-effective solution for efficient scrap management in maintain position press dies. Designed with a straightforward and functional configuration, these dies ensure reliable alignment and performance during metal stamping processes. Their economy-focused design provides an affordable option without compromising quality, making them ideal for various industries, including automotive, electronics, and general manufacturing.

The straight type economy button dies effectively retain scrap material, preventing it from interfering with the stamping process. This feature helps maintain tool alignment, reduce wear and tear, and minimize production downtime. As a result, manufacturers benefit from improved efficiency, reduced scrap rates, and consistent production quality.

Made from durable materials, these dies are engineered for long-lasting performance, ensuring they withstand the demands of high-speed and high-pressure stamping operations. Their user-friendly design allows for easy installation and integration into existing press systems, making them a versatile choice for diverse applications.

For manufacturers seeking an economical yet efficient option, straight type economy scrap retention button dies deliver excellent value. They enhance operational efficiency, support high-quality output, and optimize production workflows, making them a reliable choice for maintaining precision and reducing costs in metal stamping processes.