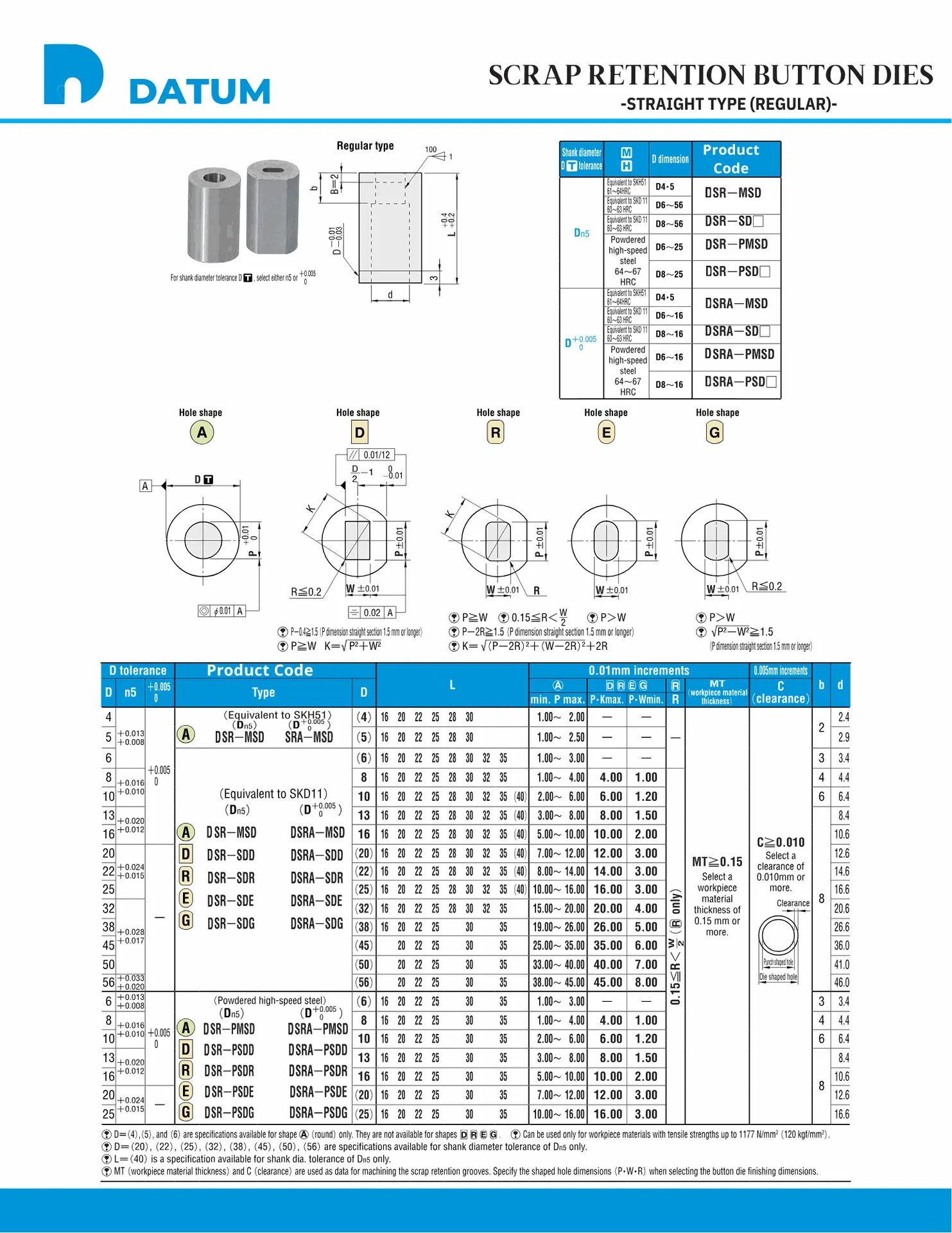

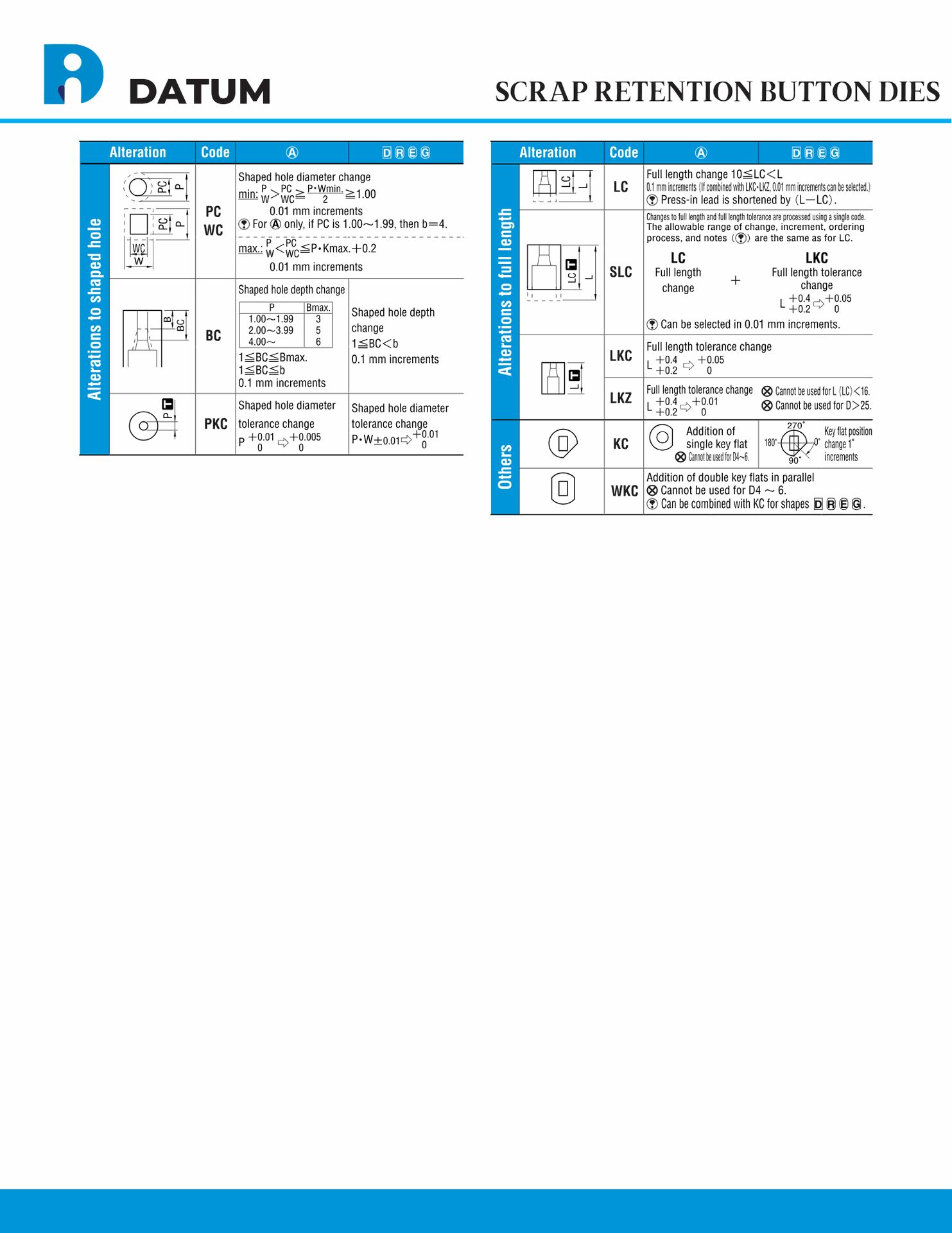

SCRAP RETENTION BUTTON DIES

-Straight Type (Regular)-

Scrap retention button dies (straight type, regular) are designed for efficient scrap management in maintain position press dies. Their straight design ensures precise alignment and stability during high-speed stamping operations. These dies effectively retain scrap material, preventing interference with the stamping process and reducing downtime. Ideal for industries like automotive and electronics, they enhance productivity and ensure consistent, high-quality results. With durable construction and reliable performance, straight type regular scrap retention button dies are an excellent choice for optimizing metal stamping efficiency.

Scrap retention button dies (straight type, regular) are essential tools for efficient scrap management and precision in maintain position press dies. Designed with a straight configuration, these dies ensure proper alignment and stability during high-speed and high-pressure stamping operations. Their primary function is to securely hold scrap material, preventing it from disrupting the stamping process or causing tool misalignment.

Manufacturers in industries such as automotive, aerospace, and electronics benefit from these dies' ability to reduce downtime, improve productivity, and maintain consistent quality. By effectively retaining scrap, they minimize waste, lower operational costs, and streamline production workflows. The straight type regular design is particularly suited for applications where durability and accuracy are critical.

Crafted from high-quality materials, these dies offer exceptional wear resistance, extending tool life and reducing maintenance requirements. Their robust construction ensures reliable performance even in demanding production environments. With a focus on precision, they contribute to producing high-quality stamped components while maintaining operational efficiency.

Investing in straight type regular scrap retention button dies is a practical choice for manufacturers seeking to enhance the efficiency and reliability of their metal stamping processes, ensuring consistent results and cost-effective operations.