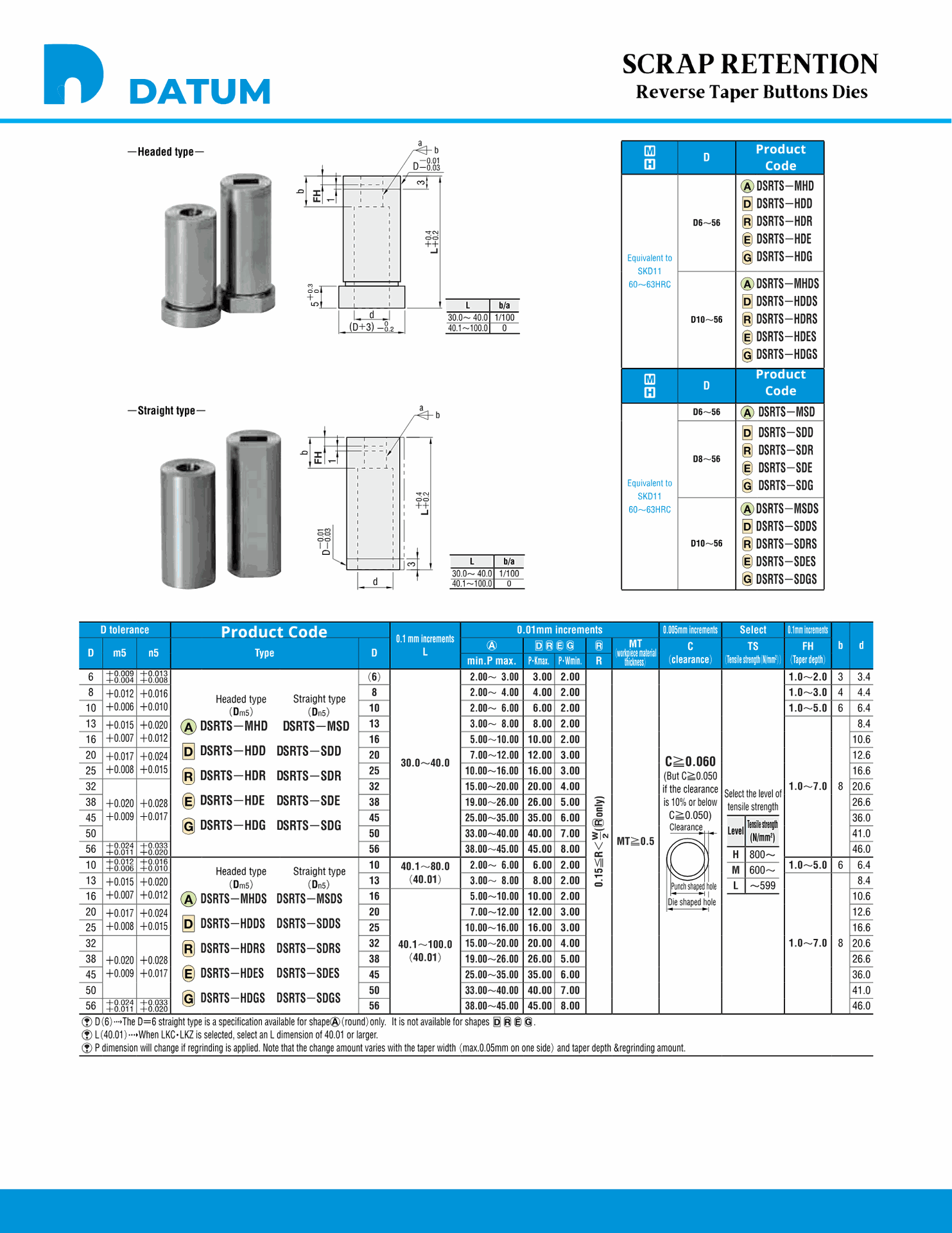

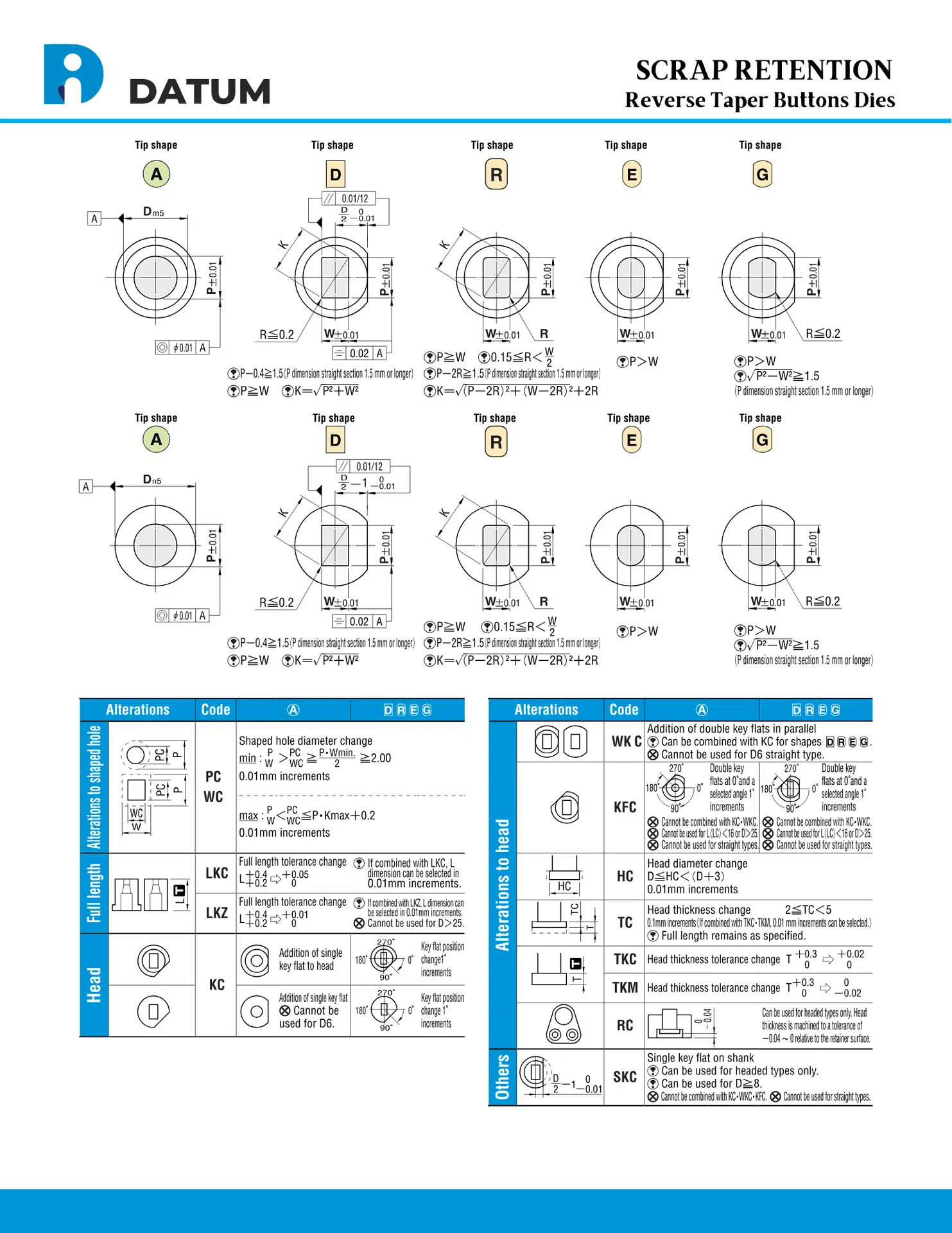

SCRAP RETENTION

Reverse Taper Buttons Dies

Reverse taper buttons dies are engineered to ensure effective scrap retention in maintain position press dies. With their reverse taper design, these dies securely hold scrap material during the stamping process, preventing it from interfering with the operation. This design helps maintain a clean workspace, improving stamping accuracy and production efficiency. Ideal for industries like automotive, aerospace, and electronics, reverse taper buttons dies enhance tool life, reduce downtime, and ensure high-quality, consistent results in metal stamping operations.

Reverse taper buttons dies are crucial for effective scrap retention in maintain position press dies. These dies feature a reverse taper design that securely captures and holds scrap material during the stamping process, preventing any interference with the operation. This ensures a clean and organized workspace, which is essential for maintaining high stamping accuracy and product quality.

The reverse taper design provides optimal scrap retention while minimizing misalignment and reducing downtime. This feature ensures smooth operation in high-speed and high-pressure environments, improving overall production efficiency. Reverse taper buttons dies also help extend the life of tooling and equipment by preventing scrap material from causing wear and damage.

These dies are ideal for industries that require precision and reliability, including automotive, aerospace, and electronics. By securely retaining scrap, reverse taper buttons dies contribute to better control and consistency in metal stamping processes.

Investing in reverse taper buttons dies offers numerous benefits, including reduced maintenance costs, increased productivity, and consistent, high-quality stamping results. They are an essential solution for manufacturers aiming to streamline operations and improve overall workflow, ensuring a more efficient and effective stamping process in metalworking applications.