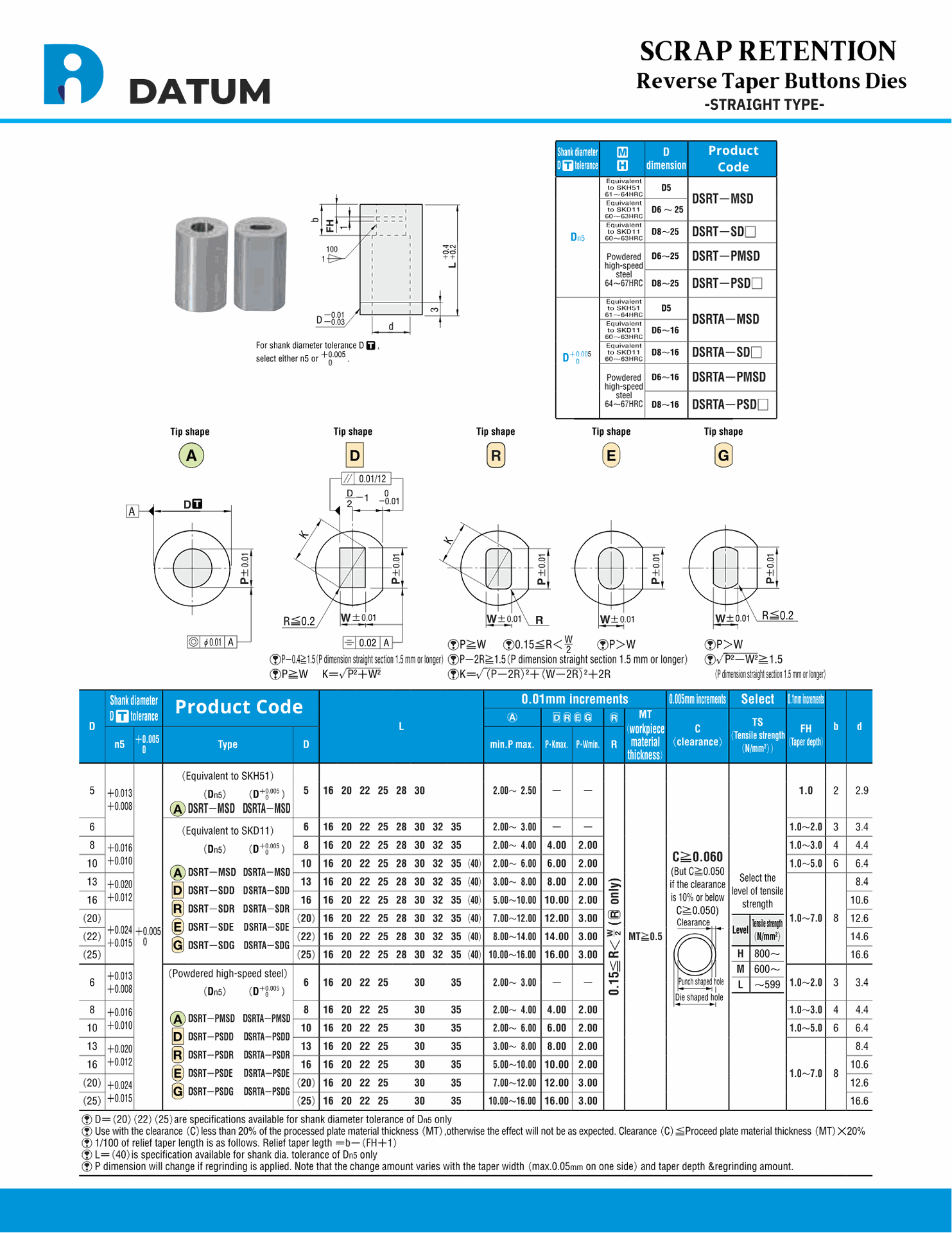

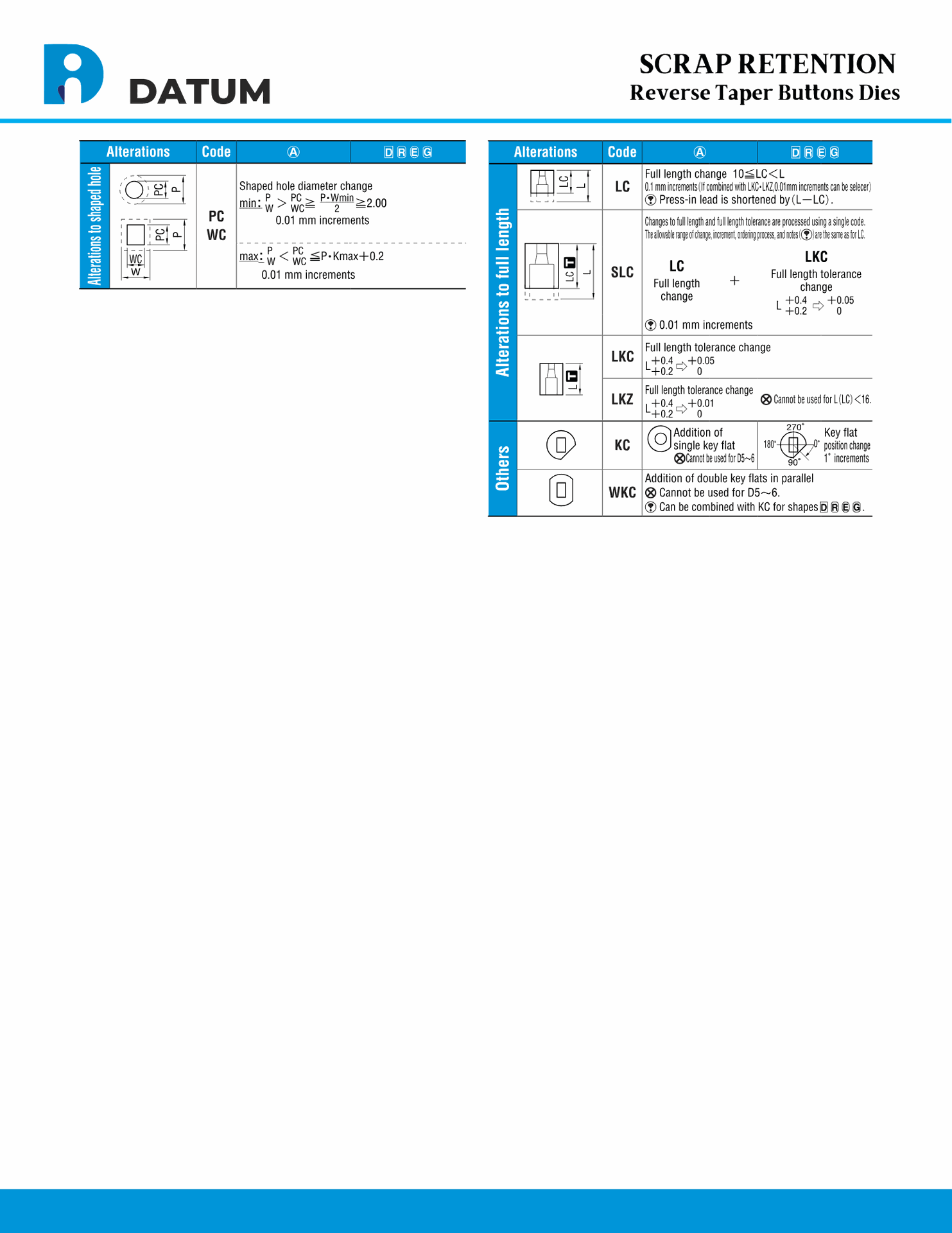

SCRAP RETENTION

Reverse Taper Buttons Dies (Straight Type )

Reverse taper buttons dies (straight type) are essential components for effective scrap retention in maintain position press dies. Featuring a straight design, these dies securely hold scrap material, preventing it from disrupting the stamping process and ensuring a clean workspace. Built for durability, they withstand high-speed and high-pressure operations, delivering consistent performance. Ideal for industries like automotive and electronics, these dies enhance production efficiency by reducing downtime and maintaining precision. Optimize your stamping process with reliable scrap retention solutions for superior results.

Reverse taper buttons dies (straight type) are vital tools for effective scrap retention in maintain position press dies. These dies feature a straight design combined with a reverse taper profile, ensuring that scrap material is securely held in place during the stamping process. This prevents loose scrap from interfering with the operation, maintaining a clean and efficient workspace and reducing production disruptions.

Engineered for durability, straight-type reverse taper buttons dies are built to withstand high-speed and high-pressure stamping operations. Their robust construction ensures long-lasting performance, minimizing maintenance and replacement needs. These dies are particularly well-suited for industries such as automotive, aerospace, and electronics, where precision and efficiency are critical for production success.

By securely retaining scrap material, these dies help enhance the accuracy and quality of stamped components. They contribute to smoother operations by reducing the risk of tool damage caused by stray scraps, ultimately improving production efficiency and reducing downtime.

Investing in reverse taper buttons dies (straight type) ensures a reliable scrap retention solution, optimized for modern stamping applications. For manufacturers aiming to achieve high-quality results and streamlined operations, these dies are an indispensable component in metalworking processes.