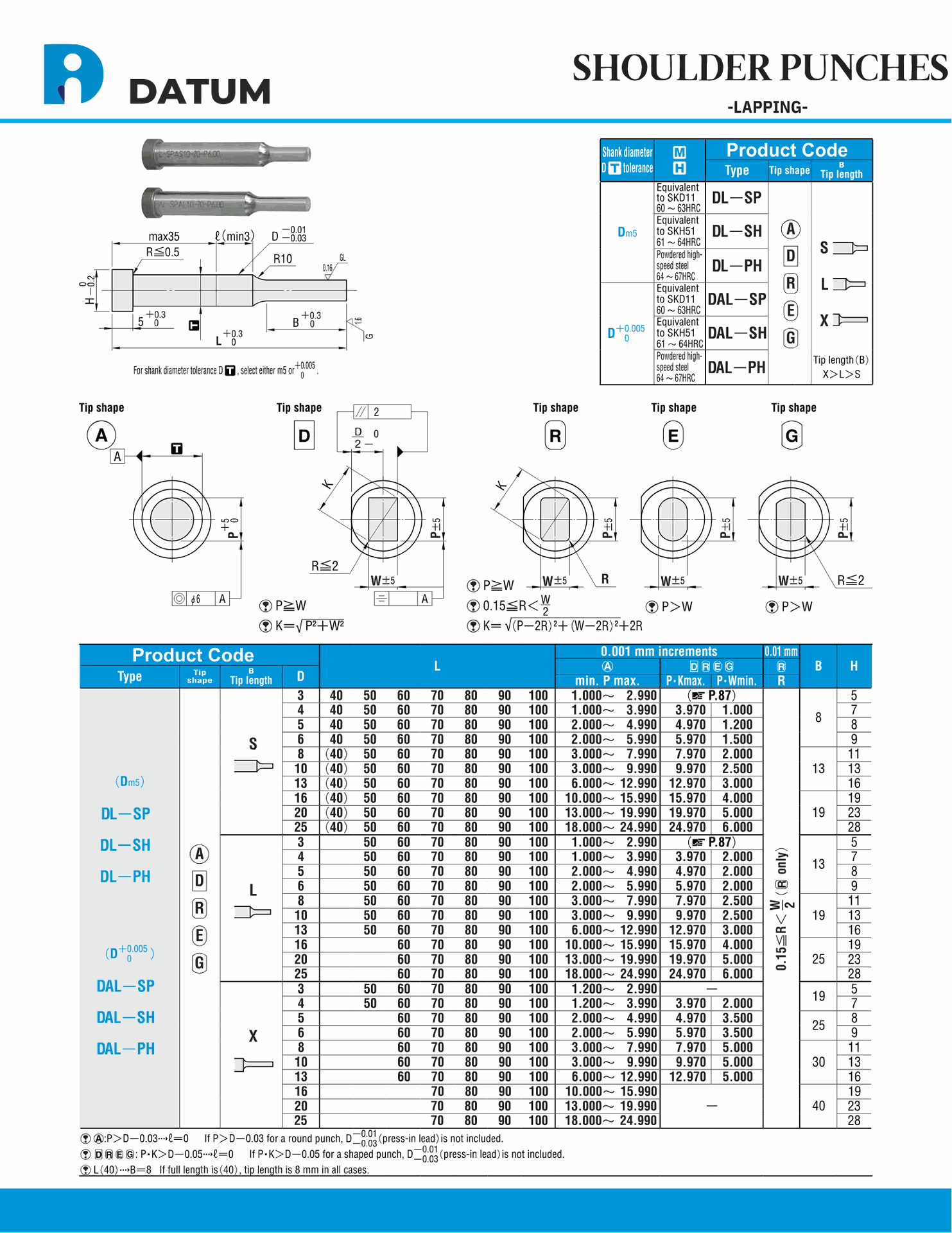

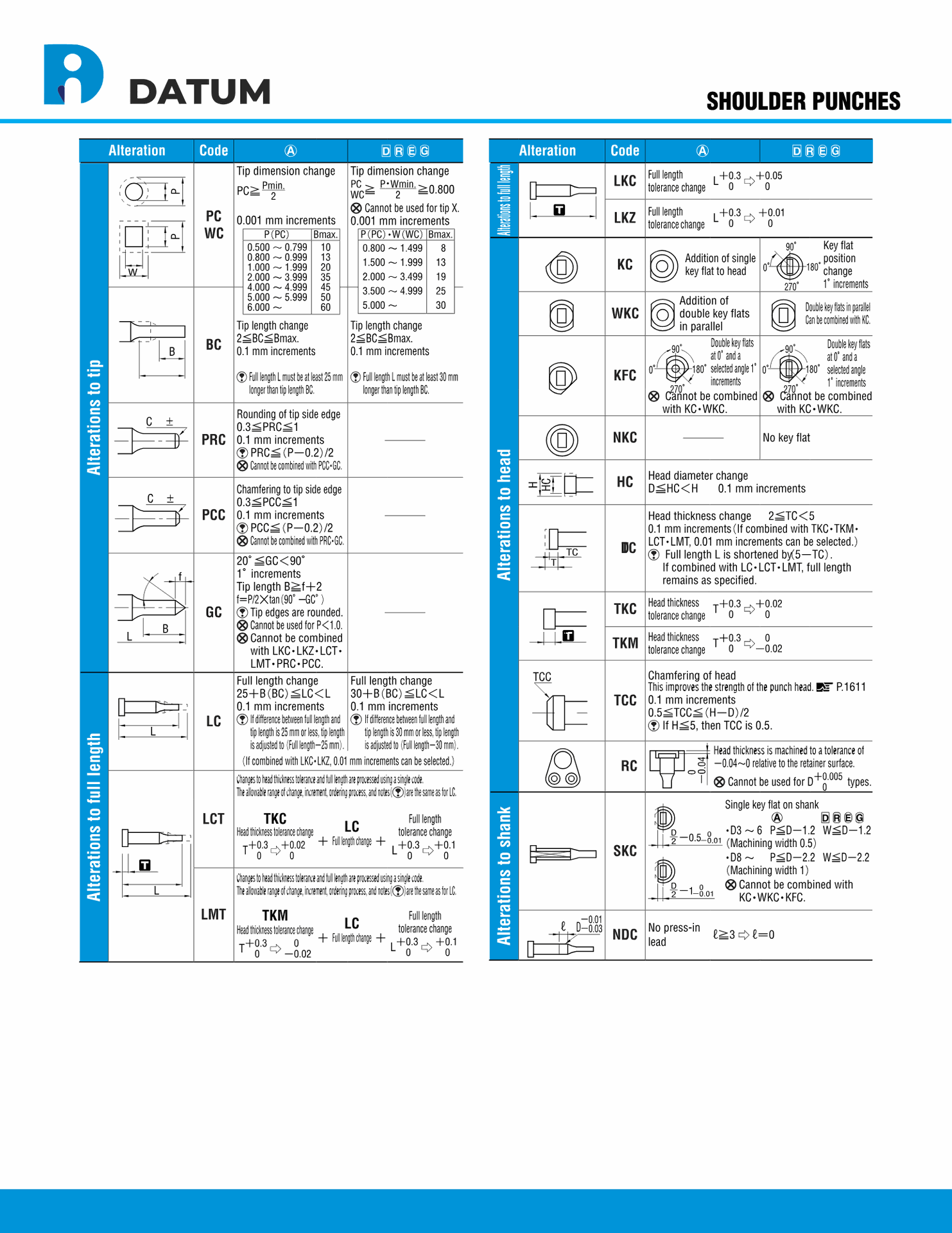

SHOULDER PUNCHES

Lapping

SHOULDER PUNCHES with lapping finish are engineered for precision and durability in heavy-load, press-in-die applications. The lapping process ensures a smooth, uniform surface that enhances the punch's performance, improving its ability to maintain position within the die. This results in more accurate and reliable manufacturing, even under high-pressure conditions. Ideal for industries such as automotive, aerospace, and metalworking, these shoulder punches provide superior wear resistance and extended tool life, reducing maintenance needs and downtime. Trust SHOULDER PUNCHES with lapping for consistent, high-quality results.

SHOULDER PUNCHES with lapping finish are specifically designed for high-performance and durability in heavy-load applications, ensuring precision in maintaining position when pressed in dies. The lapping process creates a perfectly smooth, uniform surface on the punch, enhancing its ability to fit securely within the die while reducing wear and tear. This improved surface finish ensures better efficiency and extended tool life, even in the most demanding conditions.

Ideal for industries such as automotive, aerospace, and metalworking, these shoulder punches are built to withstand the high pressures associated with press-in-die applications. The precision lapping technique not only improves the punch's strength and resilience but also enhances its ability to maintain alignment, reducing operational disruptions caused by misalignment or tool wear.

SHOULDER PUNCHES with lapping are an essential choice for manufacturers seeking consistency and high-quality results while minimizing downtime and maintenance costs. By investing in these high-quality punches, businesses can experience increased productivity and long-term tool reliability, optimizing both performance and profitability in the long run. Choose SHOULDER PUNCHES with lapping for superior precision, durability, and performance in all heavy-load press-in-die applications.