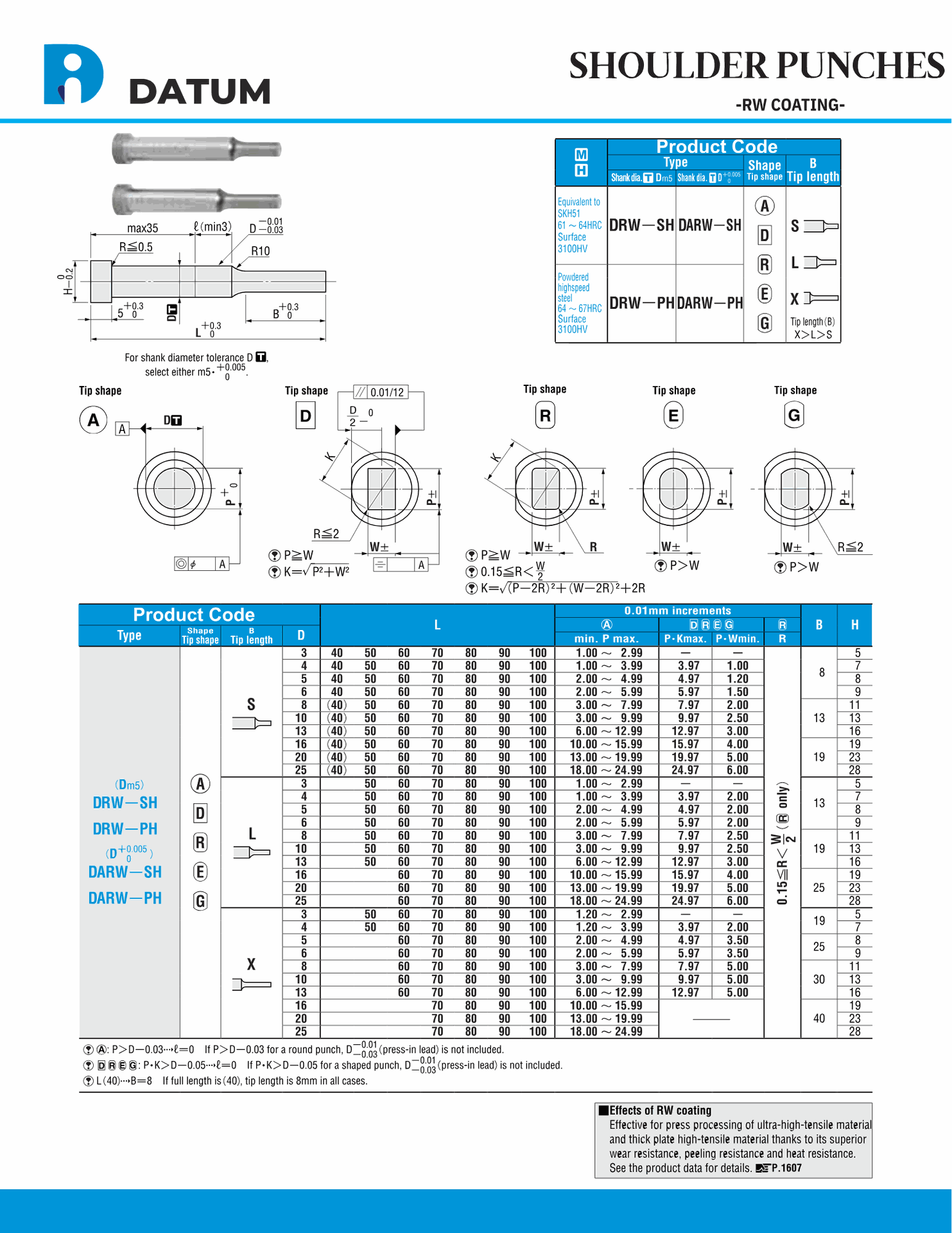

SHOULDER PUNCHES

RW Coating

SHOULDER PUNCHES with RW Coating are designed for superior performance in heavy-load press-in-die applications. The advanced RW (Reinforced Wear) Coating ensures exceptional resistance to wear, abrasion, and heat, making these punches ideal for high-stress environments. Engineered for precision, they maintain accurate positioning within the die, enhancing efficiency and product quality. Their durable construction reduces tool wear, minimizing maintenance and downtime. Perfect for automotive, aerospace, and industrial applications, these shoulder punches deliver reliable performance, extending tool life and ensuring optimal results in every operation.

SHOULDER PUNCHES with RW Coating are the ideal choice for demanding heavy-load press-in-die applications, offering unmatched durability and performance. The advanced RW (Reinforced Wear) Coating enhances resistance against wear, heat, and abrasion, ensuring long-lasting reliability even in high-stress industrial operations. These punches are meticulously designed to maintain precise positioning within the die, improving product quality and operational efficiency.

The RW Coating minimizes friction and tool degradation, reducing maintenance requirements and extending the service life of the punches. This makes them perfect for applications in industries such as automotive, aerospace, and heavy machinery, where consistent performance and precision are critical.

By maintaining stability and durability under heavy loads, these shoulder punches reduce downtime and optimize production processes. Whether in progressive dies or transfer dies, their robust construction and advanced coating provide unparalleled performance in high-pressure environments.

Investing in SHOULDER PUNCHES with RW Coating ensures efficiency, precision, and cost-effectiveness for all your metal stamping and forming needs. Trust these punches to deliver exceptional results, supporting the most rigorous manufacturing processes while enhancing tool longevity and reducing operational costs.