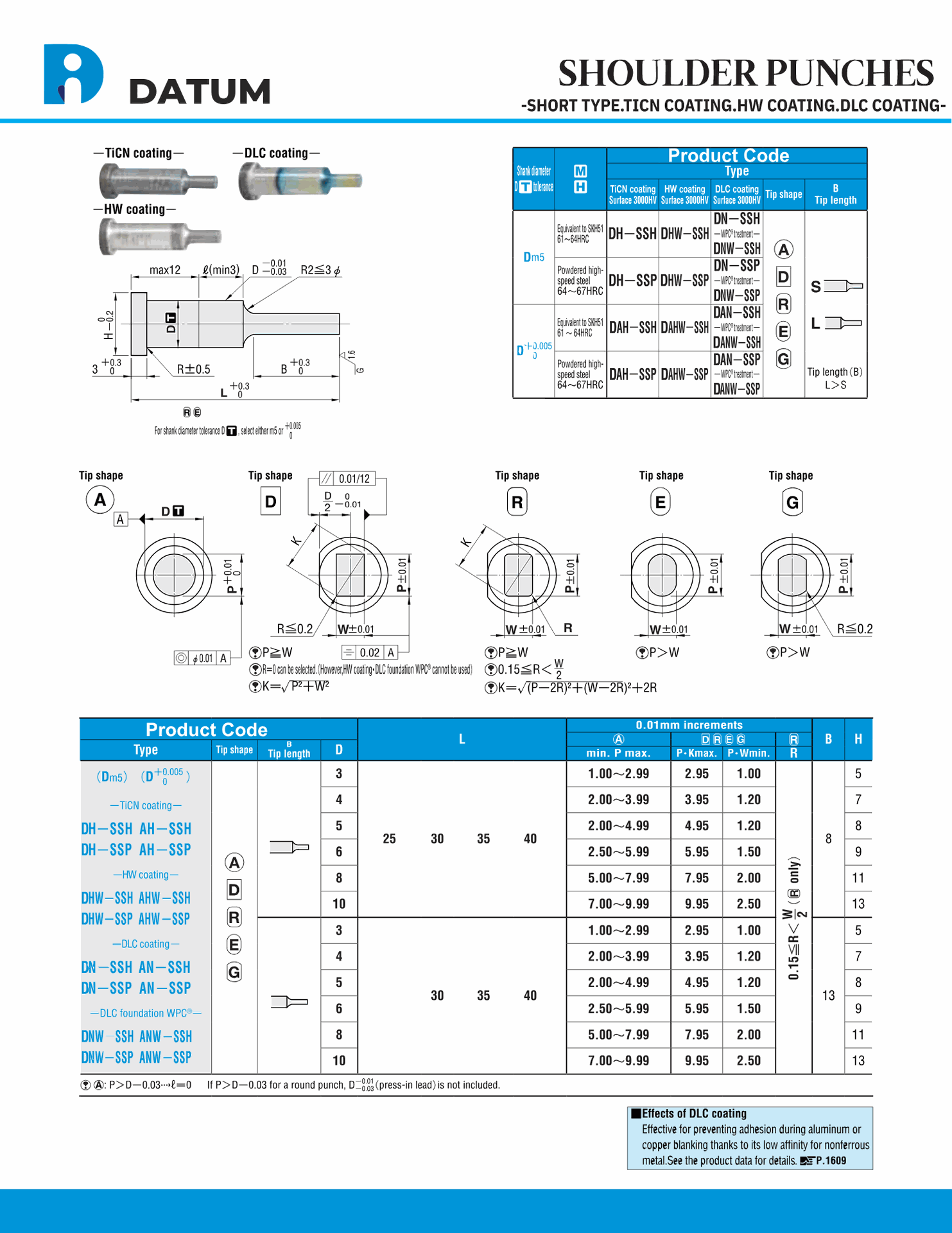

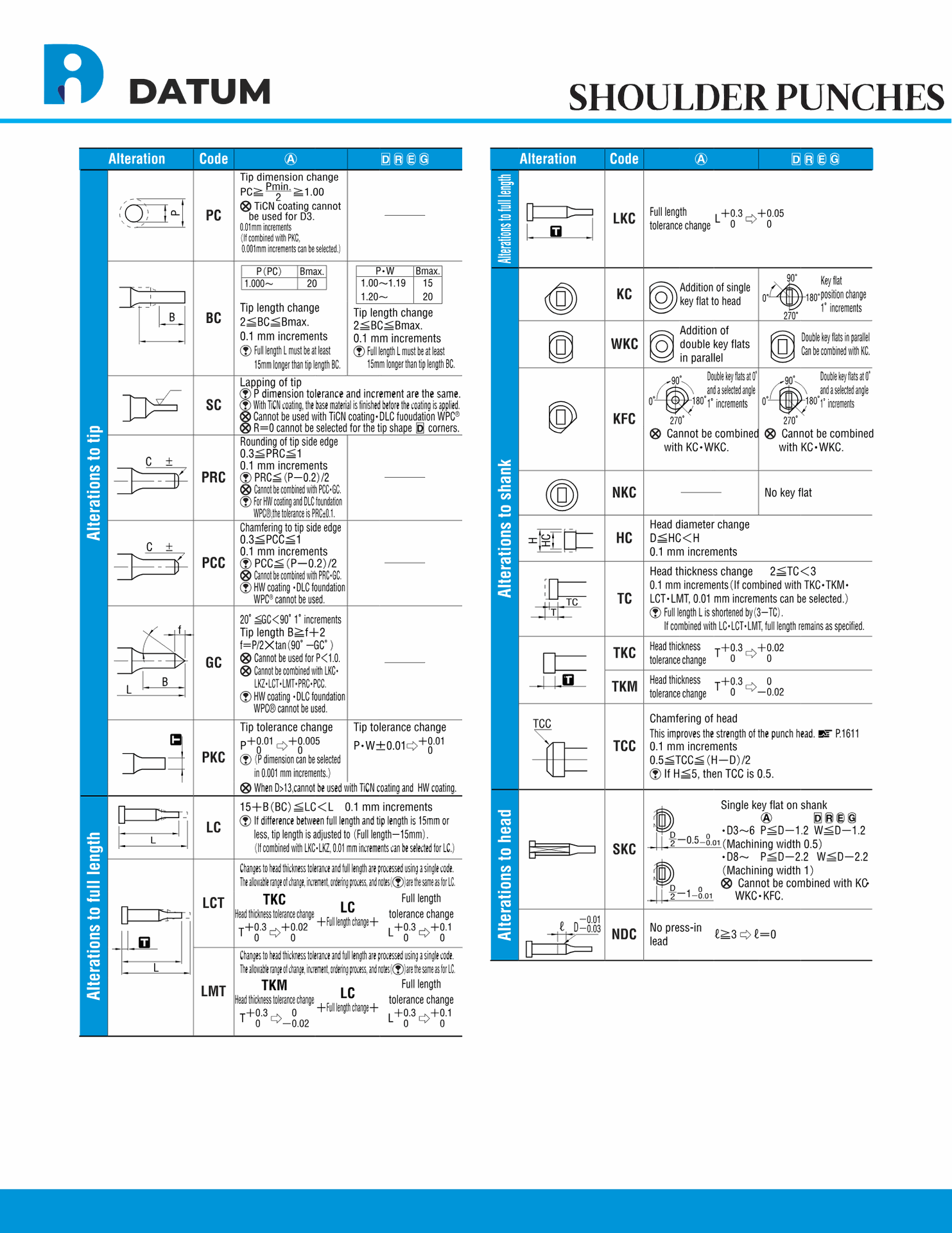

SHOULDER PUNCHES

Short Type Ticn Coating HW Coating DLC Coating

Shoulder Punches Short Type with TiCN, HW, and DLC coatings are tailored for high-precision maintain position press-in-die applications. These punches deliver exceptional durability and wear resistance, ensuring consistent performance in demanding environments. The TiCN coating enhances surface hardness, HW coating boosts longevity, and DLC coating provides superior friction reduction. Ideal for industries like automotive, aerospace, and metal fabrication, these punches excel in heavy-load operations. Trust Shoulder Punches Short Type for reliable, efficient, and long-lasting die-press solutions that meet your production needs.

Shoulder Punches in the Short Type design are built to meet the demands of modern manufacturing processes, ensuring precision and durability in maintain-position press-in-die operations. These punches are essential for industries like automotive, aerospace, and metal fabrication, where high efficiency and long-lasting tools are critical.

The TiCN coating enhances the punches with superior hardness and wear resistance, allowing them to perform efficiently under heavy loads and high-pressure conditions. This coating also improves the surface quality, reducing friction during operation. The HW coating provides enhanced toughness and resistance to thermal degradation, extending the tool's lifespan and reducing maintenance downtime. For applications where minimal friction and high-performance efficiency are necessary, the DLC coating ensures reduced material adhesion and smoother operations, making it ideal for precision-driven tasks.

The compact Short Type design is optimized for intricate die applications, allowing for easy installation in limited spaces while maintaining structural integrity. Whether used for punching, stamping, or forming, these punches deliver consistent results with minimal wear, ensuring reliable output for high-volume production.

Invest in Shoulder Punches Short Type with advanced coatings to elevate your manufacturing efficiency, tool longevity, and overall product quality.