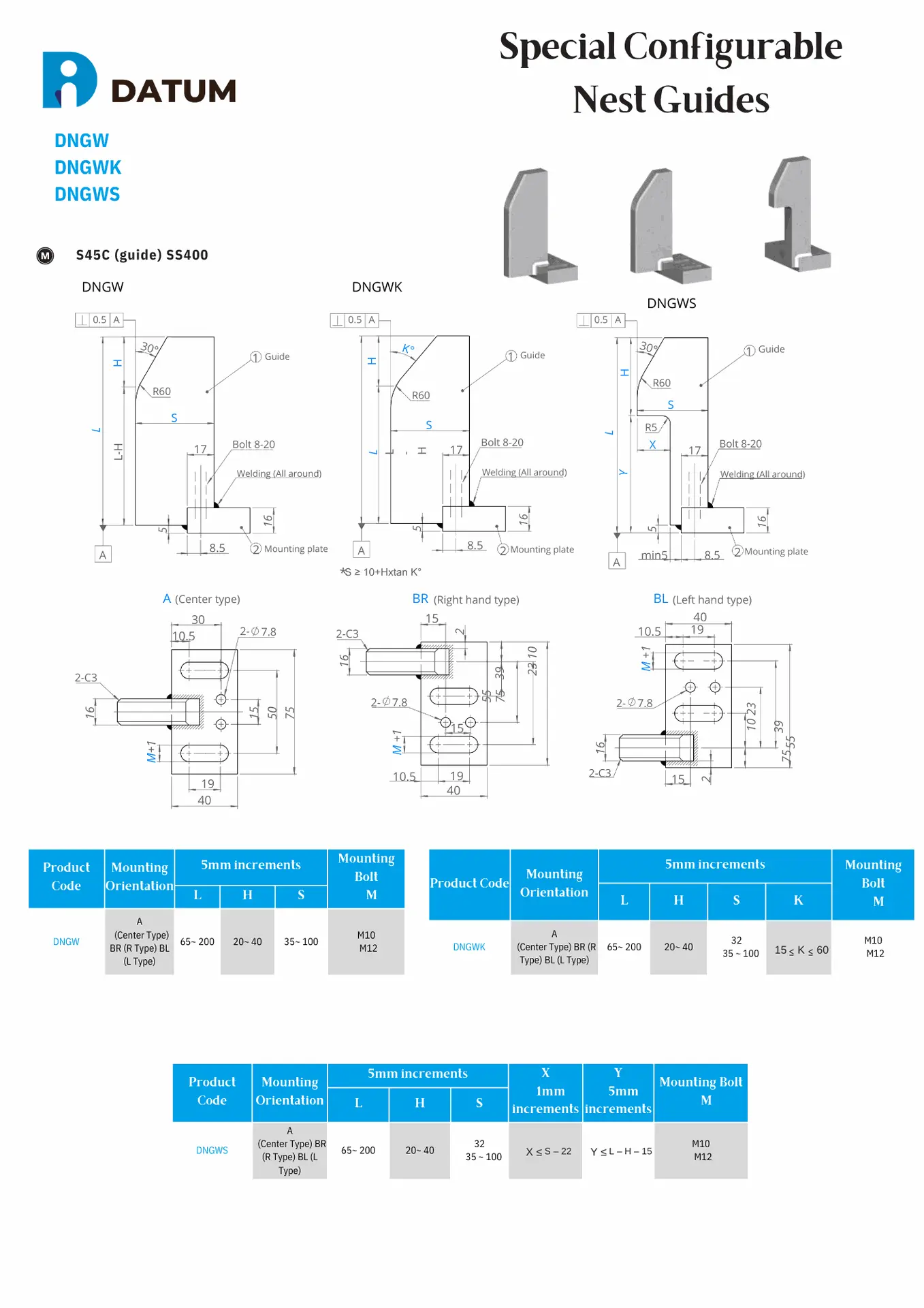

Special Configurable Nest Guides-DNGWK

The Special Configurable Nest Guides - DNGWK are engineered to ensure precise alignment and stability in die applications, crucial for maintaining the correct positioning during pressing operations. These versatile guides offer customizable configurations, allowing manufacturers to adapt them to specific operational needs effortlessly. Constructed from durable materials, the DNGWK guides withstand heavy use while promoting safety and efficiency in the workplace. Their easy installation and adjustment features save time and enhance workflow, making them an essential addition to any die maintenance strategy for improved productivity and product quality.

Special Configurable Nest Guides - DNGWK are a critical component for maintaining precise positioning in die applications during pressing operations. These innovative guides are designed to accommodate a wide range of configurations, making them highly versatile for various manufacturing processes. With the ability to customize the setup according to specific requirements, the DNGWK guides ensure optimal alignment and stability, which is essential for achieving accurate and consistent results.

Constructed from high-quality materials, the DNGWK guides are built to withstand the demands of heavy usage in industrial environments, providing long-lasting durability and reliability. Their robust design minimizes wear and tear, reducing maintenance costs and downtime, which is crucial for maximizing productivity in your operations.

The installation of Special Configurable Nest Guides is straightforward, allowing for quick adjustments that save time and enhance workflow efficiency. By integrating these guides into your pressing operations, you can ensure that your dies maintain their position accurately, reducing the risk of errors and improving overall product quality.

In addition to their practical benefits, DNGWK guides contribute to safer working conditions by providing stability and support, which is especially important in high-speed manufacturing settings. Overall, these guides are an essential investment for any manufacturer looking to optimize their die maintenance strategy, increase productivity, and enhance the quality of their products.