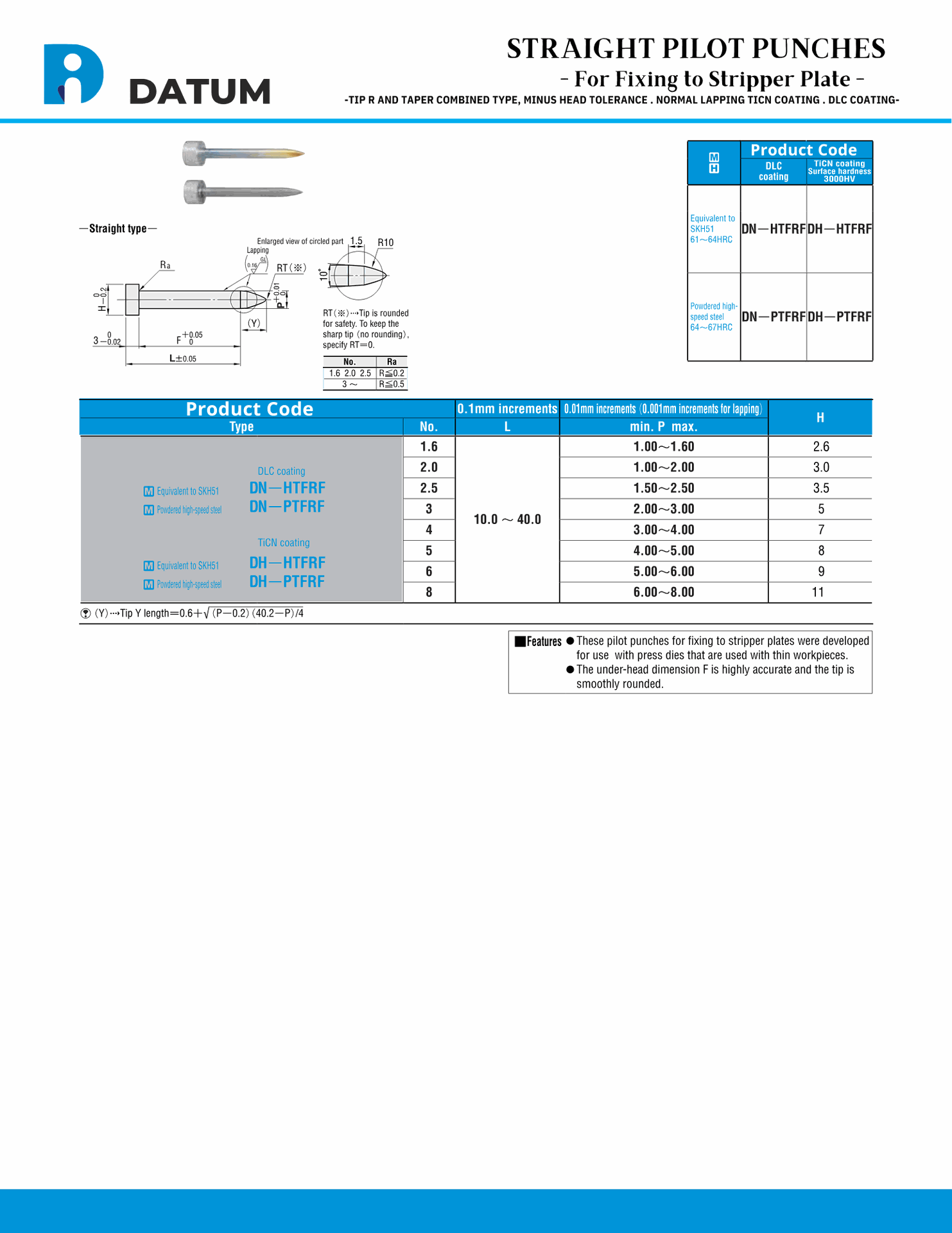

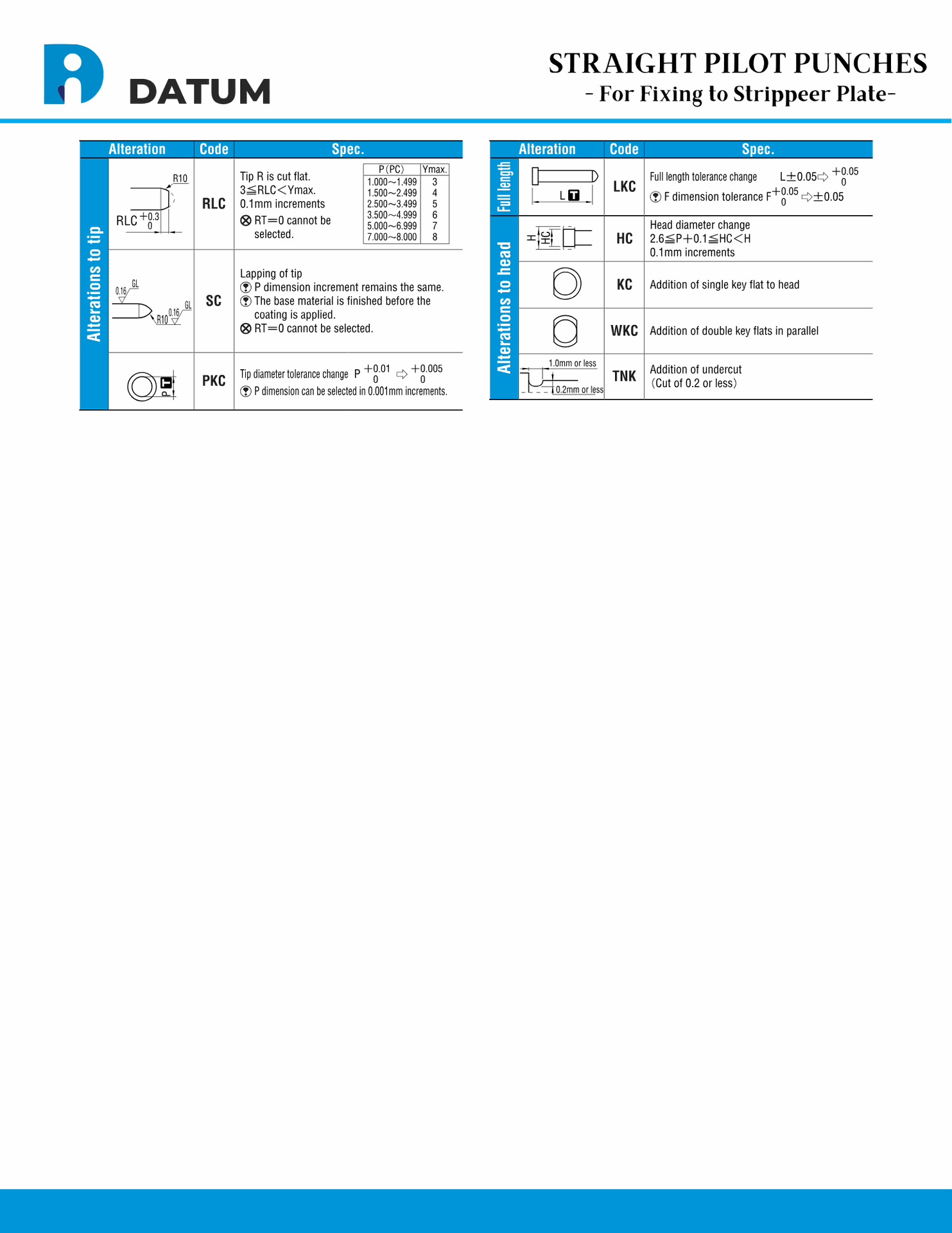

STRAIGHT PILOT PUNCHES

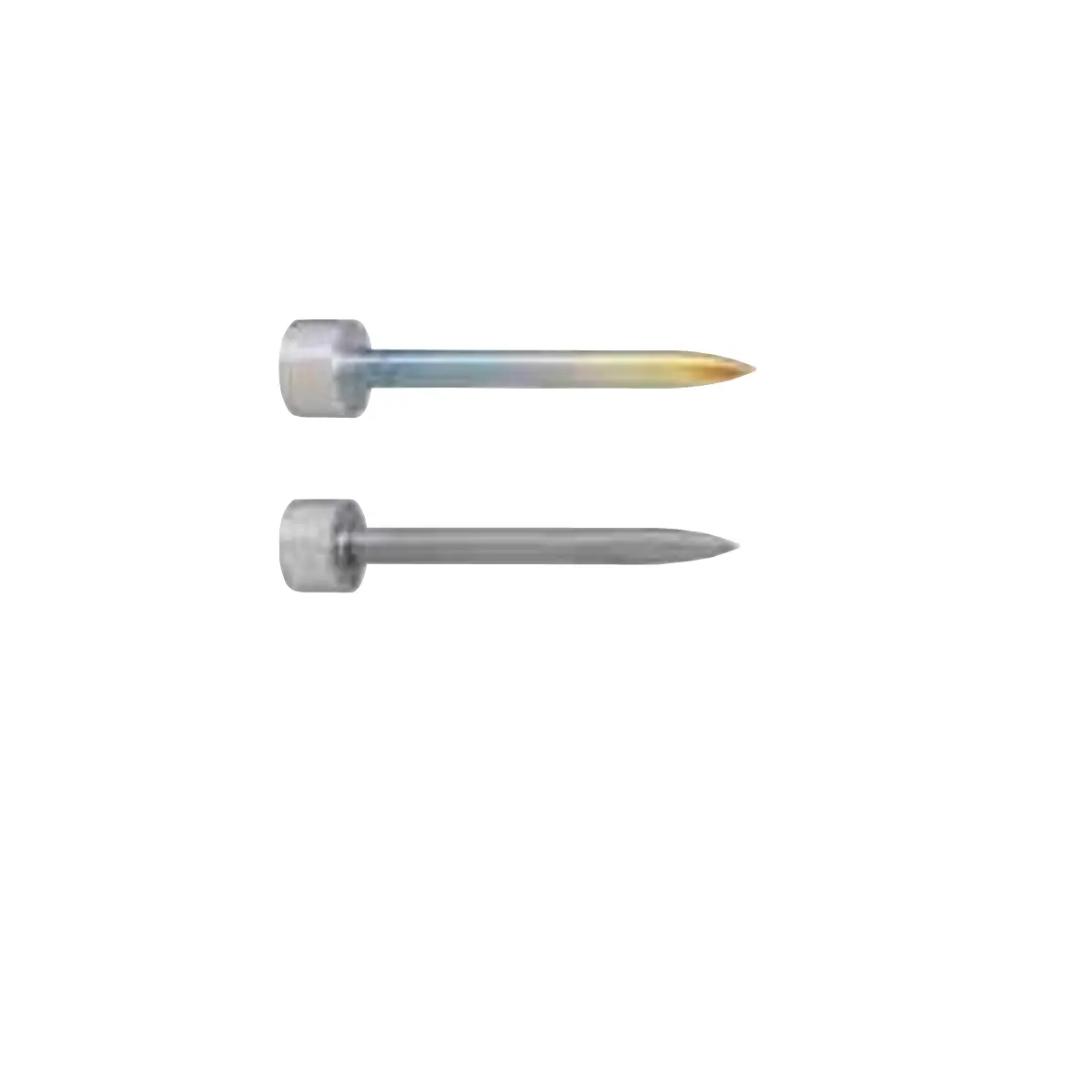

For Fixing to Stripper Plate (Tip R and Taper Combind Type, Minus Head Tolerance ,Normal Ticn Coating,DLC Coating)

Straight pilot punches with Tip R and taper combined type, minus head tolerance, TiCN, and DLC coatings are designed for high-precision performance in maintain position press dies. The combined Tip R and taper ensure accurate alignment, while minus head tolerance offers secure fitting. TiCN coating provides wear resistance, and DLC coating adds low friction and durability. Ideal for industries like automotive and electronics, these punches enhance tool life, reduce downtime, and ensure consistent, high-quality results in metal stamping operations.

Straight pilot punches with Tip R and taper combined type, minus head tolerance, and advanced coatings like TiCN (Titanium Carbonitride) and DLC (Diamond-Like Carbon) are precision-engineered for optimal performance in maintain position press dies. These punches are designed to meet the high demands of metal stamping operations, ensuring accuracy, durability, and efficiency.

The Tip R and taper combined design enhances material alignment, ensuring clean piercings and reducing deformation during stamping. Minus head tolerance guarantees a secure fit with the stripper plate, minimizing misalignments and ensuring stable performance even in high-speed applications.

TiCN coating provides superior hardness and wear resistance, significantly extending tool life and reducing maintenance needs. DLC coating further enhances the punches by delivering a low-friction, high-durability surface, improving performance and enabling smoother operations. These coatings work together to optimize stamping efficiency and ensure consistent, high-quality results.

Ideal for industries like automotive, aerospace, and electronics, these straight pilot punches deliver precise, reliable performance while reducing downtime and enhancing productivity. For manufacturers seeking high-performance solutions, these punches are a cost-effective choice to meet modern production demands and achieve superior stamping results.