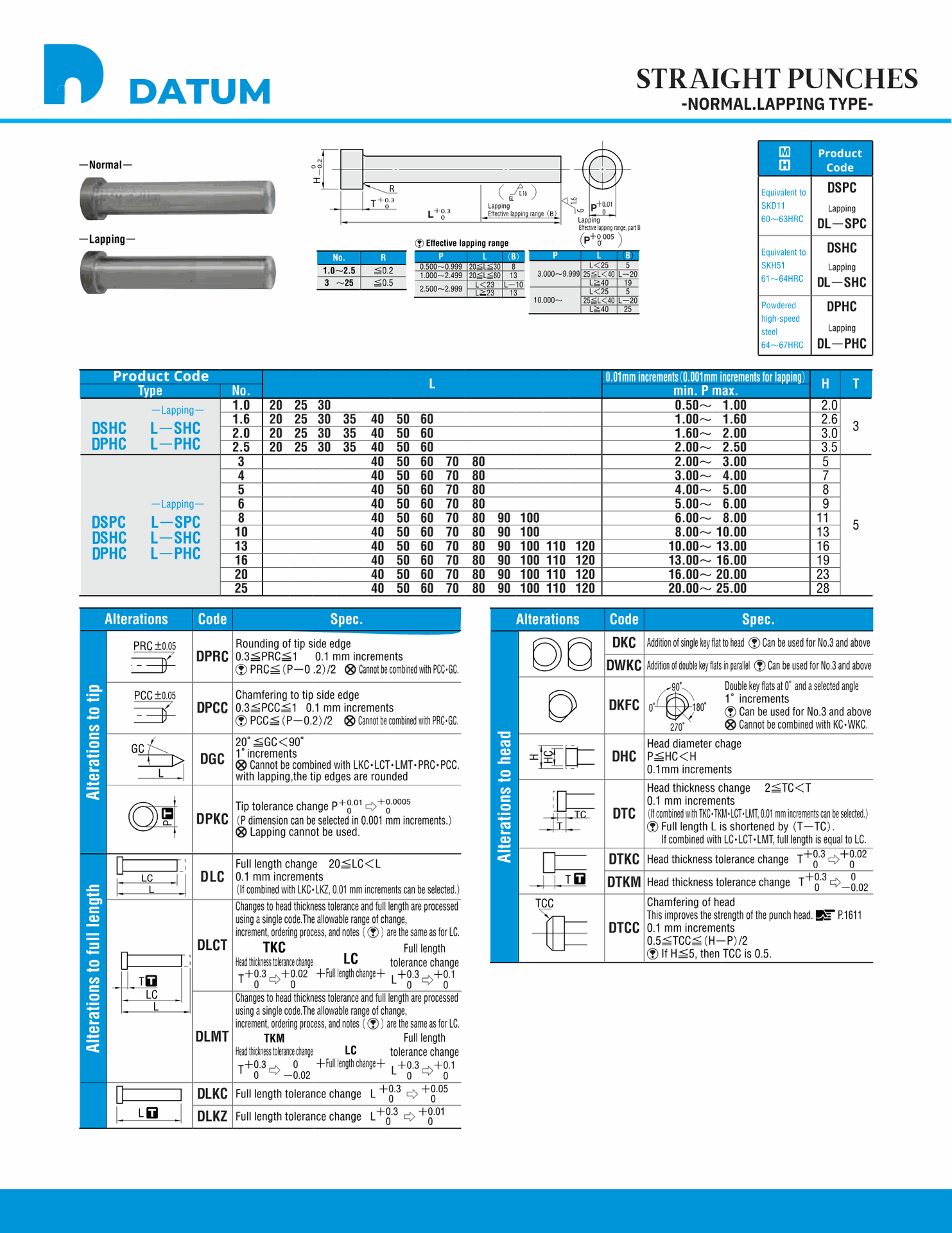

STRAIGHT PUNCHES

Normal Lapping Type

Straight Punches in the Normal Lapping Type are precision-engineered tools designed for reliable performance in press-in-die applications. These punches ensure accurate alignment and optimal positioning, making them ideal for industries requiring high precision and durability. The lapping finish enhances surface smoothness, reducing friction and wear during operation. Perfect for maintaining consistent performance in high-stress environments, these punches deliver superior longevity and reduced maintenance downtime. Invest in Straight Punches Normal Lapping Type to improve productivity and ensure flawless results in your press tooling operations.

Straight Punches in the Normal Lapping Type are expertly crafted for precision and durability, ensuring seamless performance in press-in-die applications. These punches are designed to maintain accurate positioning and alignment, making them a reliable choice for industries requiring high performance under heavy loads. The lapping finish enhances surface smoothness, reducing friction and wear, which extends the lifespan of both the punch and the die components.

With their exceptional surface finish, Straight Punches Normal Lapping Type ensure consistent performance and minimize downtime, resulting in improved productivity and cost-efficiency. These punches are manufactured to meet stringent quality standards, providing high dimensional accuracy and compatibility with diverse tooling setups.

Ideal for use in applications where precision and reliability are critical, these punches excel in maintaining alignment and position, even in high-stress environments. Whether used in metal stamping, forming, or other pressing operations, these punches deliver optimal results.

Upgrade your press tooling with Straight Punches Normal Lapping Type to achieve enhanced operational efficiency and flawless performance. Their superior craftsmanship and long-lasting design make them a cost-effective and reliable solution for maintaining precision in every press-in-die application.