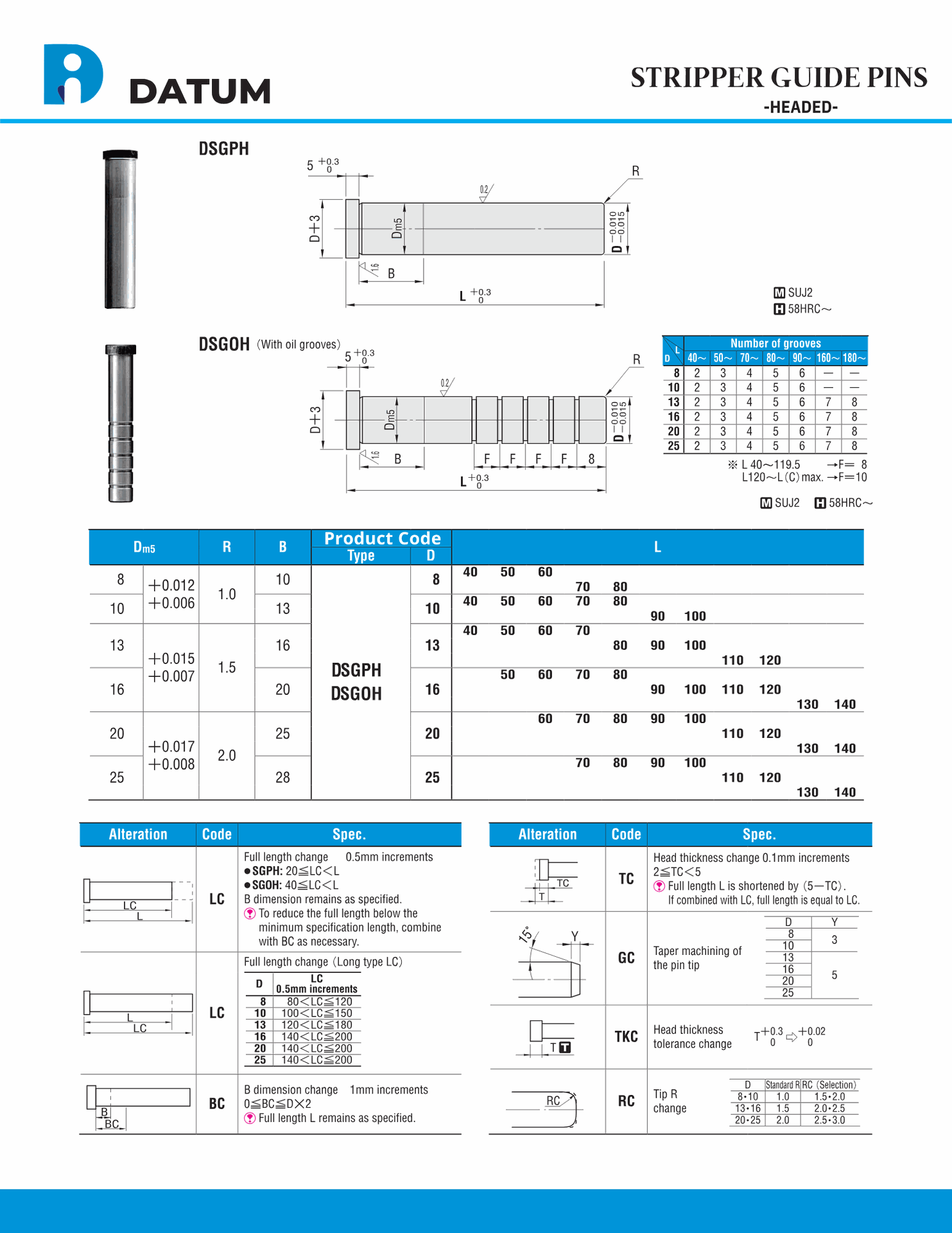

STRIPPER GUIDE PINS

Headed

Stripper guide pins (headed) are designed to maintain precise positioning in press-in-die applications, ensuring smooth and accurate die movements. These durable, high-quality pins are equipped with a head for easy installation and secure fit, providing reliable alignment and minimizing wear during repetitive press operations. Ideal for stamping, molding, and die-cutting applications, stripper guide pins help optimize production efficiency, reduce downtime, and enhance overall precision. Choose stripper guide pins for superior reliability and performance in press-in-die processes.

Stripper guide pins (headed) play a crucial role in maintaining the precise alignment and smooth functioning of dies in press-in-die operations. These high-performance pins are engineered with a head to ensure easy installation and secure positioning, making them an essential component for die-cutting, stamping, and molding applications. The headed design allows for a stable, secure fit that minimizes wear and tear, reducing the risk of misalignment or machine downtime.

Manufactured from durable materials, stripper guide pins provide consistent performance even under high-stress, high-frequency press operations. By helping to accurately guide the stripper plate during each stroke, these guide pins help to ensure smooth movement, preventing damage to both the die and the workpiece.

Ideal for a variety of industrial applications, stripper guide pins are vital for maintaining consistent results, increasing machine efficiency, and prolonging the lifespan of die tools. With the right stripper guide pins, manufacturers can improve production cycles, enhance process reliability, and achieve better-quality outcomes in their press-in-die processes. Optimize your operations with high-quality, reliable stripper guide pins for smooth, hassle-free die management.