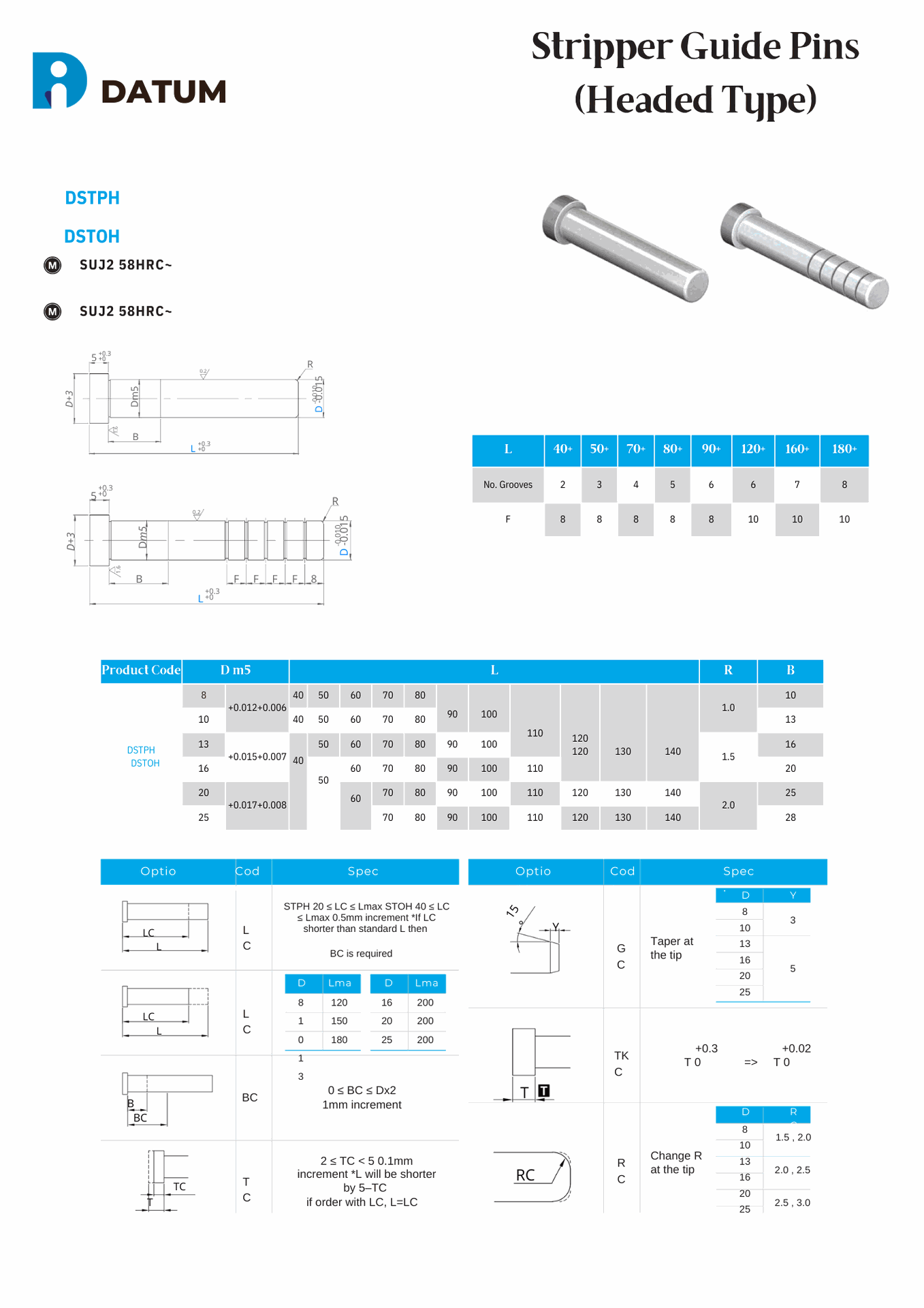

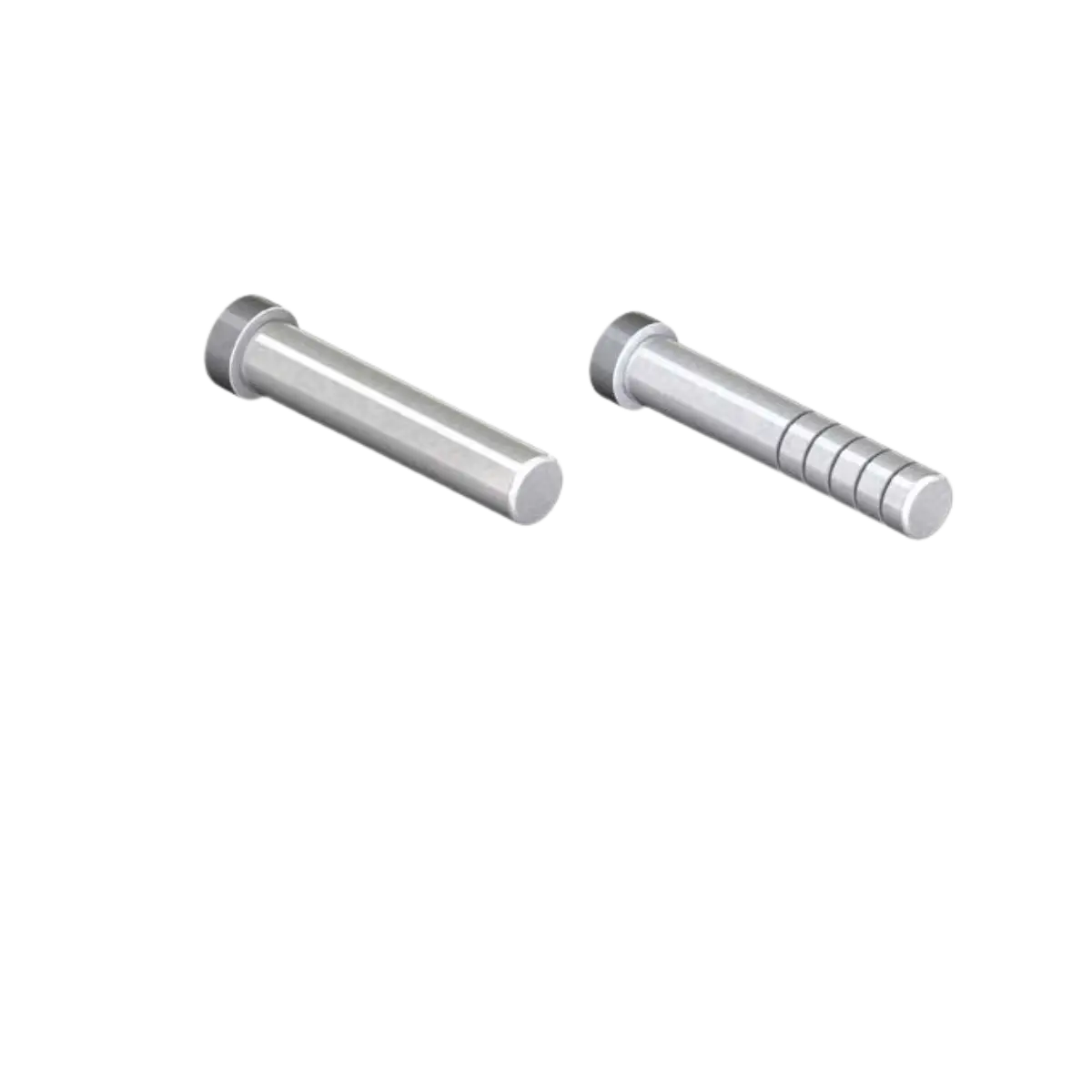

The Stripper Guide Pins DSTPH (Headed Type) are high-precision components designed to secure and maintain positioning within press-in die assemblies, enhancing alignment and stability. With a sturdy headed design, DSTPH guide pins provide reliable guidance for stripper plates, minimizing die wear and supporting consistent performance under high-stress conditions. Constructed from durable, wear-resistant materials, these pins reduce maintenance requirements and extend the life of die systems. Ideal for demanding industrial applications, DSTPH guide pins ensure precise alignment and efficient press operations, making them essential for optimized die performance.

Stripper Guide Pins (Headed Type)-DSTPH

The Stripper Guide Pins DSTPH (Headed Type) are critical components for ensuring precise alignment and positioning in press-in die systems, offering unparalleled stability and reliability in demanding industrial applications. The headed design of DSTPH guide pins provides added strength and secure fit, ensuring that stripper plates remain accurately aligned throughout press operations. This stability reduces wear on die components, effectively prolonging the lifespan of the entire die system and minimizing maintenance needs.

Made from premium, wear-resistant materials, DSTPH guide pins are built to endure high-stress environments, making them ideal for high-output manufacturing processes. These guide pins effectively prevent misalignment or shifting during operation, which can lead to premature wear and inconsistent production quality. By holding die components firmly in place, DSTPH pins support smooth, precise press actions, contributing to high-quality output and operational consistency.

For industries where alignment accuracy and die longevity are essential, Stripper Guide Pins DSTPH offer significant advantages. Their robust headed design withstands intense pressure, ensuring that all die components stay in the correct position with every press cycle. This precision is crucial for manufacturers looking to optimize productivity while reducing downtime related to maintenance and realignment.

Incorporating DSTPH guide pins into press-in die systems enhances overall efficiency, improves alignment accuracy, and reduces costs associated with frequent maintenance. These guide pins are an invaluable asset for high-precision operations, providing the durability and reliability required to maintain performance standards and achieve consistent production quality over extended periods.