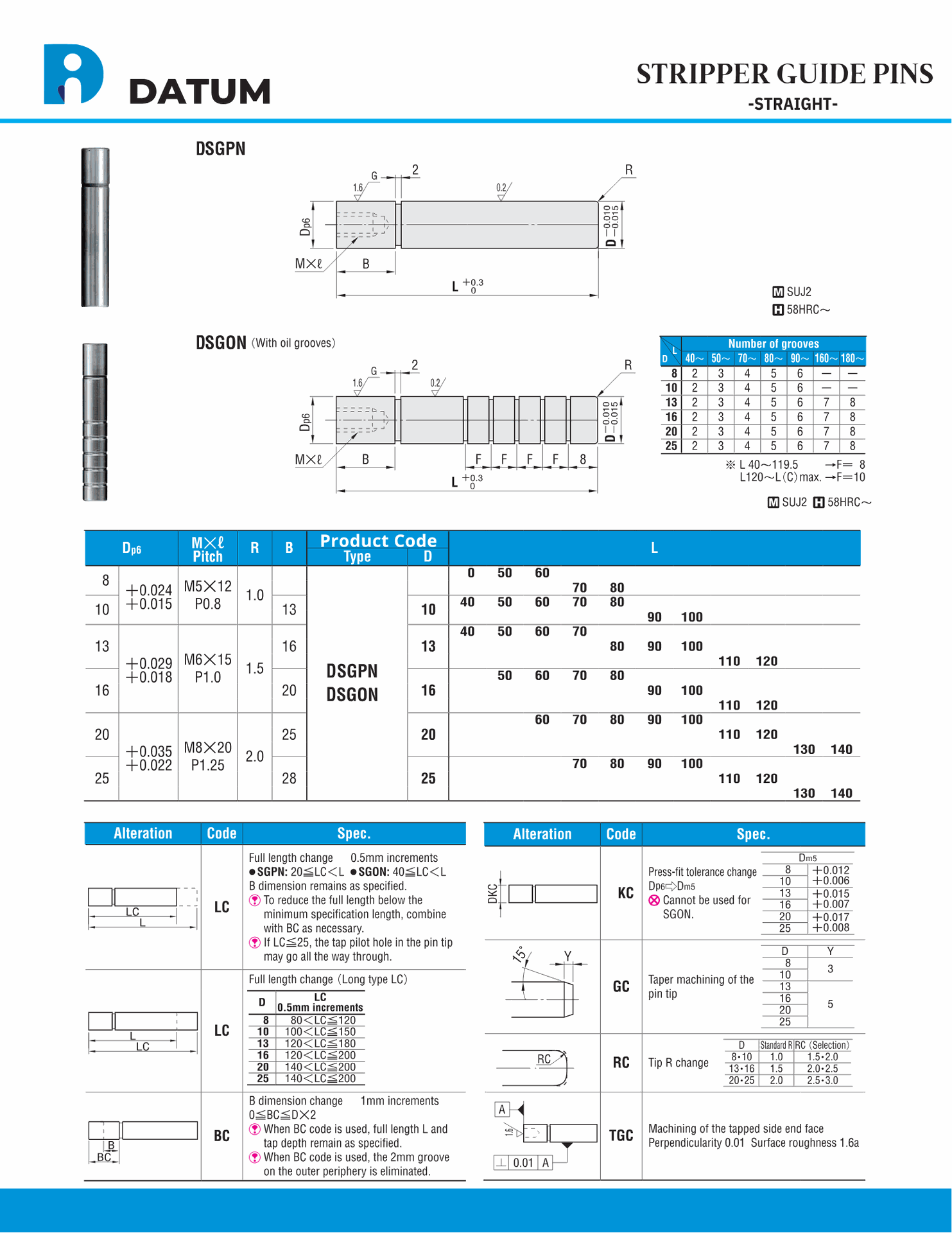

STRIPPER GUIDE PINS

Straight

Straight stripper guide pins are essential components in maintaining precise alignment during press-in-die operations. These pins ensure smooth, accurate movement of the stripper plate, reducing wear and misalignment during die-cutting, stamping, or molding processes. Designed for durability, straight guide pins help enhance machine efficiency and reduce downtime, ensuring optimal performance in high-stress environments. Perfect for industries seeking reliable and consistent results, straight stripper guide pins help improve production cycles and extend the lifespan of die tools in press-in-die applications.

Straight stripper guide pins play a crucial role in maintaining precise alignment and functionality in press-in-die operations. These pins are specifically engineered to guide the stripper plate efficiently, ensuring that it moves smoothly and stays aligned throughout the die-cutting, stamping, or molding processes. By minimizing misalignment, these guide pins help to reduce tool wear and improve overall machine efficiency.

Made from high-quality materials, straight stripper guide pins are designed for durability and long-lasting performance in demanding environments. They are essential for industries requiring high precision, such as automotive, aerospace, and manufacturing. The straight design offers a straightforward and reliable solution for positioning, keeping the stripper plate firmly in place during critical operations.

By investing in high-quality straight stripper guide pins, manufacturers can achieve faster production cycles, reduce downtime, and extend the lifespan of their dies and other tools. Their role in minimizing misalignment also results in better-quality finished products, contributing to reduced scrap rates and operational costs.

For consistent, reliable results in press-in-die applications, straight stripper guide pins are an indispensable component that ensures precise, efficient, and long-term performance in any manufacturing environment.