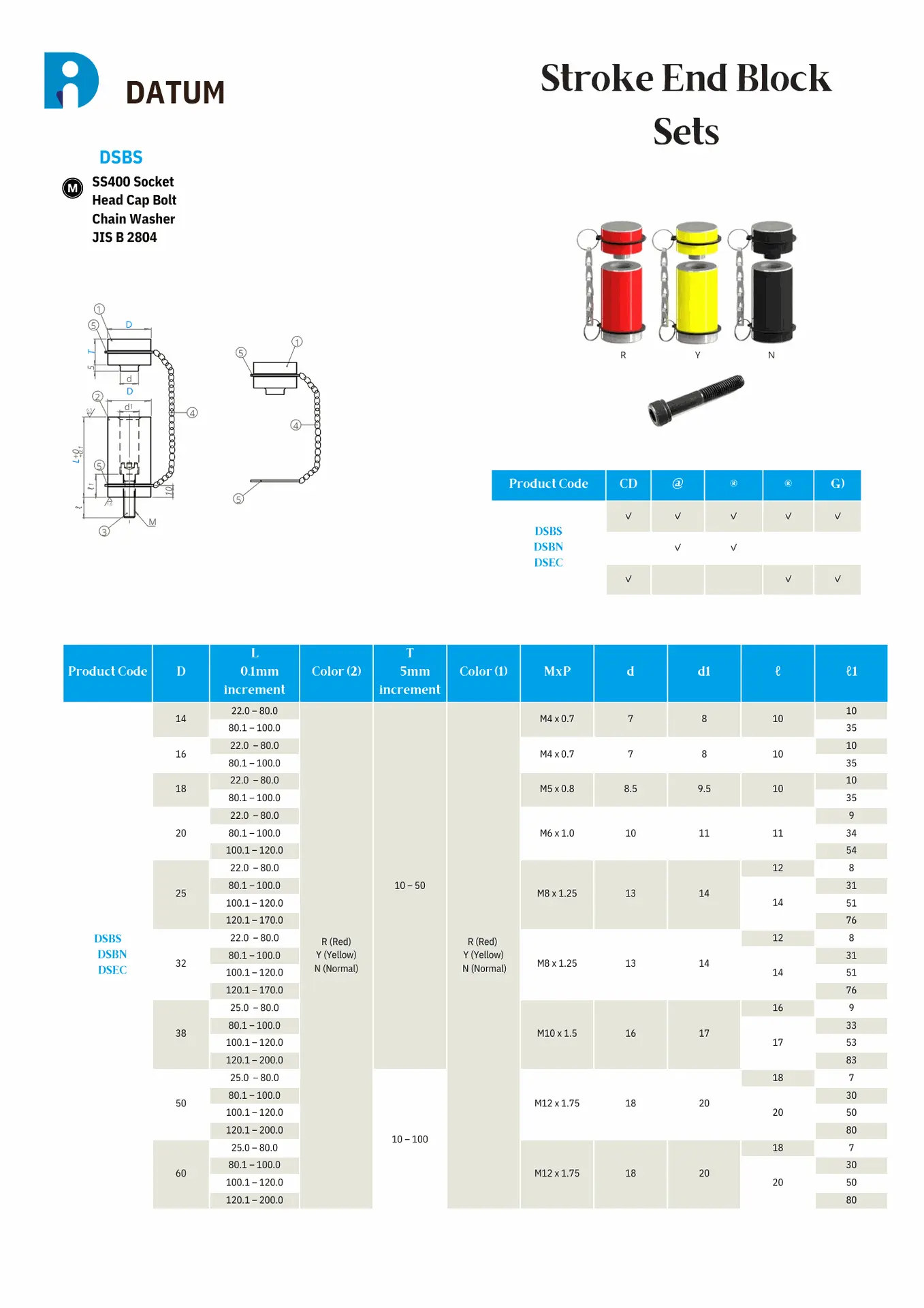

Stroke End Block Sets-DSBS

The Stroke End Block Sets-DSBS is a high-performance press die component designed for accurate stroke control, durability, and stability in metal stamping and die-cutting applications. Manufactured from high-strength materials, it offers excellent wear resistance and impact absorption, reducing machine stress and ensuring consistent performance in high-load environments. With its precise construction, the DSBS Stroke End Block Set enhances manufacturing accuracy, minimizes downtime, and extends tool life, making it an ideal choice for automotive, electronics, and precision engineering industries. Designed for seamless integration into various press die systems, it optimizes production efficiency while reducing maintenance costs.

Select Dia & Length to view more details

- 14-22r-10r

- 14-22r-15r

- 14-22r-20r

- 14-22r-25r

- 14-22r-30r

- 14-22r-35r

- 14-22r-40r

- 14-22r-45r

- 14-22r-50r

- 14-23r-10r

- 14-23r-15r

- 14-23r-20r

- 14-23r-25r

- 14-23r-30r

- 14-23r-35r

- 14-23r-40r

- 14-23r-45r

- 14-23r-50r

- 14-24r-10r

- 14-24r-15r

- 14-24r-20r

- 14-24r-25r

- 14-24r-30r

- 14-24r-35r

- 14-24r-40r

- 14-24r-45r

- 14-24r-50r

- 14-25r-10r

- 14-25r-15r

- 14-25r-20r

- 14-25r-25r

- 14-25r-30r

- 14-25r-35r

- 14-25r-40r

- 14-25r-45r

- 14-25r-50r

- 14-26r-10r

- 14-26r-15r

- 14-26r-20r

- 14-26r-25r

- 14-26r-30r

- 14-26r-35r

- 14-26r-40r

- 14-26r-45r

- 14-26r-50r

- 14-27r-10r

- 14-27r-15r

- 14-27r-20r

- 14-27r-25r

- 14-27r-30r

- 14-27r-35r

- 14-27r-40r

- 14-27r-45r

- 14-27r-50r

- 14-28r-10r

- 14-28r-15r

- 14-28r-20r

- 14-28r-25r

- 14-28r-30r

- 14-28r-35r

- 14-28r-40r

- 14-28r-45r

- 14-28r-50r

- 14-29r-10r

- 14-29r-15r

- 14-29r-20r

- 14-29r-25r

- 14-29r-30r

- 14-29r-35r

- 14-29r-40r

- 14-29r-45r

- 14-29r-50r

- 14-30r-10r

- 14-30r-15r

- 14-30r-20r

- 14-30r-25r

- 14-30r-30r

- 14-30r-35r

- 14-30r-40r

- 14-30r-45r

- 14-30r-50r

- 14-31r-10r

- 14-31r-15r

- 14-31r-20r

- 14-31r-25r

- 14-31r-30r

- 14-31r-35r

- 14-31r-40r

- 14-31r-45r

- 14-31r-50r

- 14-32r-10r

- 14-32r-15r

- 14-32r-20r

- 14-32r-25r

- 14-32r-30r

- 14-32r-35r

- 14-32r-40r

- 14-32r-45r

- 14-32r-50r

- 14-33r-10r

- 14-33r-15r

- 14-33r-20r

- 14-33r-25r

- 14-33r-30r

- 14-33r-35r

- 14-33r-40r

- 14-33r-45r

- 14-33r-50r

- 14-34r-10r

- 14-34r-15r

- 14-34r-20r

- 14-34r-25r

- 14-34r-30r

- 14-34r-35r

- 14-34r-40r

- 14-34r-45r

- 14-34r-50r

- 14-35r-10r

- 14-35r-15r

- 14-35r-20r

- 14-35r-25r

- 14-35r-30r

- 14-35r-35r

- 14-35r-40r

- 14-35r-45r

- 14-35r-50r

- 14-36r-10r

- 14-36r-15r

- 14-36r-20r

- 14-36r-25r

- 14-36r-30r

- 14-36r-35r

- 14-36r-40r

- 14-36r-45r

- 14-36r-50r

- 14-37r-10r

- 14-37r-15r

- 14-37r-20r

- 14-37r-25r

- 14-37r-30r

- 14-37r-35r

- 14-37r-40r

- 14-37r-45r

- 14-37r-50r

- 14-38r-10r

- 14-38r-15r

- 14-38r-20r

- 14-38r-25r

- 14-38r-30r

- 14-38r-35r

- 14-38r-40r

- 14-38r-45r

- 14-38r-50r

- 14-39r-10r

- 14-39r-15r

- 14-39r-20r

- 14-39r-25r

- 14-39r-30r

- 14-39r-35r

- 14-39r-40r

- 14-39r-45r

- 14-39r-50r

- 14-40r-10r

- 14-40r-15r

- 14-40r-20r

- 14-40r-25r

- 14-40r-30r

- 14-40r-35r

- 14-40r-40r

- 14-40r-45r

- 14-40r-50r

- 14-41r-10r

- 14-41r-15r

- 14-41r-20r

- 14-41r-25r

- 14-41r-30r

- 14-41r-35r

- 14-41r-40r

- 14-41r-45r

- 14-41r-50r

- 14-42r-10r

- 14-42r-15r

- 14-42r-20r

- 14-42r-25r

- 14-42r-30r

- 14-42r-35r

- 14-42r-40r

- 14-42r-45r

- 14-42r-50r

- 14-43r-10r

- 14-43r-15r

- 14-43r-20r

- 14-43r-25r

- 14-43r-30r

- 14-43r-35r

- 14-43r-40r

- 14-43r-45r

- 14-43r-50r

- 14-44r-10r

- 14-44r-15r

- 14-44r-20r

- 14-44r-25r

- 14-44r-30r

- 14-44r-35r

- 14-44r-40r

- 14-44r-45r

- 14-44r-50r

- 14-45r-10r

- 14-45r-15r

- 14-45r-20r

- 14-45r-25r

- 14-45r-30r

- 14-45r-35r

- 14-45r-40r

- 14-45r-45r

- 14-45r-50r

- 14-46r-10r

- 14-46r-15r

- 14-46r-20r

- 14-46r-25r

- 14-46r-30r

- 14-46r-35r

- 14-46r-40r

- 14-46r-45r

- 14-46r-50r

- 14-47r-10r

- 14-47r-15r

- 14-47r-20r

- 14-47r-25r

- 14-47r-30r

- 14-47r-35r

- 14-47r-40r

- 14-47r-45r

- 14-47r-50r

- 14-48r-10r

- 14-48r-15r

- 14-48r-20r

- 14-48r-25r

- 14-48r-30r

- 14-48r-35r

- 14-48r-40r

- 14-48r-45r

- 14-48r-50r

- 14-49r-10r

- 14-49r-15r

- 14-49r-20r

- 14-49r-25r

- 14-49r-30r

- 14-49r-35r

- 14-49r-40r

- 14-49r-45r

- 14-49r-50r

- 14-50r-10r

- 14-50r-15r

- 14-50r-20r

- 14-50r-25r

- 14-50r-30r

- 14-50r-35r

- 14-50r-40r

- 14-50r-45r

- 14-50r-50r

- 14-51r-10r

- 14-51r-15r

- 14-51r-20r

- 14-51r-25r

- 14-51r-30r

- 14-51r-35r

- 14-51r-40r

- 14-51r-45r

- 14-51r-50r

- 14-52r-10r

- 14-52r-15r

- 14-52r-20r

- 14-52r-25r

- 14-52r-30r

- 14-52r-35r

- 14-52r-40r

- 14-52r-45r

- 14-52r-50r

- 14-53r-10r

- 14-53r-15r

- 14-53r-20r

- 14-53r-25r

- 14-53r-30r

- 14-53r-35r

- 14-53r-40r

- 14-53r-45r

- 14-53r-50r

- 14-54r-10r

- 14-54r-15r

- 14-54r-20r

- 14-54r-25r

- 14-54r-30r

- 14-54r-35r

- 14-54r-40r

- 14-54r-45r

- 14-54r-50r

- 14-55r-10r

- 14-55r-15r

- 14-55r-20r

- 14-55r-25r

- 14-55r-30r

- 14-55r-35r

- 14-55r-40r

- 14-55r-45r

- 14-55r-50r

- 14-56r-10r

- 14-56r-15r

- 14-56r-20r

- 14-56r-25r

- 14-56r-30r

- 14-56r-35r

- 14-56r-40r

- 14-56r-45r

- 14-56r-50r

- 14-57r-10r

- 14-57r-15r

- 14-57r-20r

- 14-57r-25r

- 14-57r-30r

- 14-57r-35r

- 14-57r-40r

- 14-57r-45r

- 14-57r-50r

- 14-58r-10r

- 14-58r-15r

- 14-58r-20r

- 14-58r-25r

- 14-58r-30r

- 14-58r-35r

- 14-58r-40r

- 14-58r-45r

- 14-58r-50r

- 14-59r-10r

- 14-59r-15r

- 14-59r-20r

- 14-59r-25r

- 14-59r-30r

- 14-59r-35r

- 14-59r-40r

- 14-59r-45r

- 14-59r-50r

- 14-60r-10r

- 14-60r-15r

- 14-60r-20r

- 14-60r-25r

- 14-60r-30r

- 14-60r-35r

- 14-60r-40r

- 14-60r-45r

- 14-60r-50r

- 14-61r-10r

- 14-61r-15r

- 14-61r-20r

- 14-61r-25r

- 14-61r-30r

- 14-61r-35r

- 14-61r-40r

- 14-61r-45r

- 14-61r-50r

- 14-62r-10r

- 14-62r-15r

- 14-62r-20r

- 14-62r-25r

- 14-62r-30r

- 14-62r-35r

- 14-62r-40r

- 14-62r-45r

- 14-62r-50r

- 14-63r-10r

- 14-63r-15r

- 14-63r-20r

- 14-63r-25r

- 14-63r-30r

- 14-63r-35r

- 14-63r-40r

- 14-63r-45r

- 14-63r-50r

- 14-64r-10r

- 14-64r-15r

- 14-64r-20r

- 14-64r-25r

- 14-64r-30r

- 14-64r-35r

- 14-64r-40r

- 14-64r-45r

- 14-64r-50r

- 14-65r-10r

- 14-65r-15r

- 14-65r-20r

- 14-65r-25r

- 14-65r-30r

- 14-65r-35r

- 14-65r-40r

- 14-65r-45r

- 14-65r-50r

- 14-66r-10r

- 14-66r-15r

- 14-66r-20r

- 14-66r-25r

- 14-66r-30r

- 14-66r-35r

- 14-66r-40r

- 14-66r-45r

- 14-66r-50r

- 14-67r-10r

- 14-67r-15r

- 14-67r-20r

- 14-67r-25r

- 14-67r-30r

- 14-67r-35r

- 14-67r-40r

- 14-67r-45r

- 14-67r-50r

- 14-68r-10r

- 14-68r-15r

- 14-68r-20r

- 14-68r-25r

- 14-68r-30r

- 14-68r-35r

- 14-68r-40r

- 14-68r-45r

- 14-68r-50r

- 14-69r-10r

- 14-69r-15r

- 14-69r-20r

- 14-69r-25r

- 14-69r-30r

- 14-69r-35r

- 14-69r-40r

- 14-69r-45r

- 14-69r-50r

- 14-70r-10r

- 14-70r-15r

- 14-70r-20r

- 14-70r-25r

- 14-70r-30r

- 14-70r-35r

- 14-70r-40r

- 14-70r-45r

- 14-70r-50r

- 14-71r-10r

- 14-71r-15r

- 14-71r-20r

- 14-71r-25r

- 14-71r-30r

- 14-71r-35r

- 14-71r-40r

- 14-71r-45r

- 14-71r-50r

- 14-72r-10r

- 14-72r-15r

- 14-72r-20r

- 14-72r-25r

- 14-72r-30r

- 14-72r-35r

- 14-72r-40r

- 14-72r-45r

- 14-72r-50r

- 14-73r-10r

- 14-73r-15r

- 14-73r-20r

- 14-73r-25r

- 14-73r-30r

- 14-73r-35r

- 14-73r-40r

- 14-73r-45r

- 14-73r-50r

- 14-74r-10r

- 14-74r-15r

- 14-74r-20r

- 14-74r-25r

- 14-74r-30r

- 14-74r-35r

- 14-74r-40r

- 14-74r-45r

- 14-74r-50r

- 14-75r-10r

- 14-75r-15r

- 14-75r-20r

- 14-75r-25r

- 14-75r-30r

- 14-75r-35r

- 14-75r-40r

- 14-75r-45r

- 14-75r-50r

- 14-76r-10r

- 14-76r-15r

- 14-76r-20r

- 14-76r-25r

- 14-76r-30r

- 14-76r-35r

- 14-76r-40r

- 14-76r-45r

- 14-76r-50r

- 14-77r-10r

- 14-77r-15r

- 14-77r-20r

- 14-77r-25r

- 14-77r-30r

- 14-77r-35r

- 14-77r-40r

- 14-77r-45r

- 14-77r-50r

- 14-78r-10r

- 14-78r-15r

- 14-78r-20r

- 14-78r-25r

- 14-78r-30r

- 14-78r-35r

- 14-78r-40r

- 14-78r-45r

- 14-78r-50r

- 14-79r-10r

- 14-79r-15r

- 14-79r-20r

- 14-79r-25r

- 14-79r-30r

- 14-79r-35r

- 14-79r-40r

- 14-79r-45r

- 14-79r-50r

- 14-80r-10r

- 14-80r-15r

- 14-80r-20r

- 14-80r-25r

- 14-80r-30r

- 14-80r-35r

- 14-80r-40r

- 14-80r-45r

- 14-80r-50r

- 14-81r-10r

- 14-81r-15r

- 14-81r-20r

- 14-81r-25r

- 14-81r-30r

- 14-81r-35r

- 14-81r-40r

- 14-81r-45r

- 14-81r-50r

- 14-82r-10r

- 14-82r-15r

- 14-82r-20r

- 14-82r-25r

- 14-82r-30r

- 14-82r-35r

- 14-82r-40r

- 14-82r-45r

- 14-82r-50r

- 14-83r-10r

- 14-83r-15r

- 14-83r-20r

- 14-83r-25r

- 14-83r-30r

- 14-83r-35r

- 14-83r-40r

- 14-83r-45r

- 14-83r-50r

- 14-84r-10r

- 14-84r-15r

- 14-84r-20r

- 14-84r-25r

- 14-84r-30r

- 14-84r-35r

- 14-84r-40r

- 14-84r-45r

- 14-84r-50r

- 14-85r-10r

- 14-85r-15r

- 14-85r-20r

- 14-85r-25r

- 14-85r-30r

- 14-85r-35r

- 14-85r-40r

- 14-85r-45r

- 14-85r-50r

- 14-86r-10r

- 14-86r-15r

- 14-86r-20r

- 14-86r-25r

- 14-86r-30r

- 14-86r-35r

- 14-86r-40r

- 14-86r-45r

- 14-86r-50r

- 14-87r-10r

- 14-87r-15r

- 14-87r-20r

- 14-87r-25r

- 14-87r-30r

- 14-87r-35r

- 14-87r-40r

- 14-87r-45r

- 14-87r-50r

- 14-88r-10r

- 14-88r-15r

- 14-88r-20r

- 14-88r-25r

- 14-88r-30r

- 14-88r-35r

- 14-88r-40r

- 14-88r-45r

- 14-88r-50r

- 14-89r-10r

- 14-89r-15r

- 14-89r-20r

- 14-89r-25r

- 14-89r-30r

- 14-89r-35r

- 14-89r-40r

- 14-89r-45r

- 14-89r-50r

- 14-90r-10r

- 14-90r-15r

- 14-90r-20r

- 14-90r-25r

- 14-90r-30r

- 14-90r-35r

- 14-90r-40r

- 14-90r-45r

- 14-90r-50r

- 14-91r-10r

- 14-91r-15r

- 14-91r-20r

- 14-91r-25r

- 14-91r-30r

- 14-91r-35r

- 14-91r-40r

- 14-91r-45r

- 14-91r-50r

- 14-92r-10r

- 14-92r-15r

- 14-92r-20r

- 14-92r-25r

- 14-92r-30r

- 14-92r-35r

- 14-92r-40r

- 14-92r-45r

- 14-92r-50r

- 14-93r-10r

- 14-93r-15r

- 14-93r-20r

- 14-93r-25r

- 14-93r-30r

- 14-93r-35r

- 14-93r-40r

- 14-93r-45r

- 14-93r-50r

- 14-94r-10r

- 14-94r-15r

- 14-94r-20r

- 14-94r-25r

- 14-94r-30r

- 14-94r-35r

- 14-94r-40r

- 14-94r-45r

- 14-94r-50r

- 14-95r-10r

- 14-95r-15r

- 14-95r-20r

- 14-95r-25r

- 14-95r-30r

- 14-95r-35r

- 14-95r-40r

- 14-95r-45r

- 14-95r-50r

- 14-96r-10r

- 14-96r-15r

- 14-96r-20r

- 14-96r-25r

- 14-96r-30r

- 14-96r-35r

- 14-96r-40r

- 14-96r-45r

- 14-96r-50r

- 14-97r-10r

- 14-97r-15r

- 14-97r-20r

- 14-97r-25r

- 14-97r-30r

- 14-97r-35r

- 14-97r-40r

- 14-97r-45r

- 14-97r-50r

- 14-98r-10r

- 14-98r-15r

- 14-98r-20r

- 14-98r-25r

- 14-98r-30r

- 14-98r-35r

- 14-98r-40r

- 14-98r-45r

- 14-98r-50r

- 14-99r-10r

- 14-99r-15r

- 14-99r-20r

- 14-99r-25r

- 14-99r-30r

- 14-99r-35r

- 14-99r-40r

- 14-99r-45r

- 14-99r-50r

- 14-100r-10r

- 14-100r-15r

- 14-100r-20r

- 14-100r-25r

- 14-100r-30r

- 14-100r-35r

- 14-100r-40r

- 14-100r-45r

- 14-100r-50r

- 14-22y-10y

- 14-22y-15y

- 14-22y-20y

- 14-22y-25y

- 14-22y-30y

- 14-22y-35y

- 14-22y-40y

- 14-22y-45y

- 14-22y-50y

- 14-23y-10y

- 14-23y-15y

- 14-23y-20y

- 14-23y-25y

- 14-23y-30y

- 14-23y-35y

- 14-23y-40y

- 14-23y-45y

- 14-23y-50y

- 14-24y-10y

- 14-24y-15y

- 14-24y-20y

- 14-24y-25y

- 14-24y-30y

- 14-24y-35y

- 14-24y-40y

- 14-24y-45y

- 14-24y-50y

- 14-25y-10y

- 14-25y-15y

- 14-25y-20y

- 14-25y-25y

- 14-25y-30y

- 14-25y-35y

- 14-25y-40y

- 14-25y-45y

- 14-25y-50y

- 14-26y-10y

- 14-26y-15y

- 14-26y-20y

- 14-26y-25y

- 14-26y-30y

- 14-26y-35y

- 14-26y-40y

- 14-26y-45y

- 14-26y-50y

- 14-27y-10y

- 14-27y-15y

- 14-27y-20y

- 14-27y-25y

- 14-27y-30y

- 14-27y-35y

- 14-27y-40y

- 14-27y-45y

- 14-27y-50y

- 14-28y-10y

- 14-28y-15y

- 14-28y-20y

- 14-28y-25y

- 14-28y-30y

- 14-28y-35y

- 14-28y-40y

- 14-28y-45y

- 14-28y-50y

- 14-29y-10y

- 14-29y-15y

- 14-29y-20y

- 14-29y-25y

- 14-29y-30y

- 14-29y-35y

- 14-29y-40y

- 14-29y-45y

- 14-29y-50y

- 14-30y-10y

- 14-30y-15y

- 14-30y-20y

- 14-30y-25y

- 14-30y-30y

- 14-30y-35y

- 14-30y-40y

- 14-30y-45y

- 14-30y-50y

- 14-31y-10y

- 14-31y-15y

- 14-31y-20y

- 14-31y-25y

- 14-31y-30y

- 14-31y-35y

- 14-31y-40y

- 14-31y-45y

- 14-31y-50y

- 14-32y-10y

- 14-32y-15y

- 14-32y-20y

- 14-32y-25y

- 14-32y-30y

- 14-32y-35y

- 14-32y-40y

- 14-32y-45y

- 14-32y-50y

- 14-33y-10y

- 14-33y-15y

- 14-33y-20y

- 14-33y-25y

- 14-33y-30y

- 14-33y-35y

- 14-33y-40y

- 14-33y-45y

- 14-33y-50y

- 14-34y-10y

- 14-34y-15y

- 14-34y-20y

- 14-34y-25y

- 14-34y-30y

- 14-34y-35y

- 14-34y-40y

- 14-34y-45y

- 14-34y-50y

- 14-35y-10y

- 14-35y-15y

- 14-35y-20y

- 14-35y-25y

- 14-35y-30y

- 14-35y-35y

- 14-35y-40y

- 14-35y-45y

- 14-35y-50y

- 14-36y-10y

- 14-36y-15y

- 14-36y-20y

- 14-36y-25y

- 14-36y-30y

- 14-36y-35y

- 14-36y-40y

- 14-36y-45y

- 14-36y-50y

- 14-37y-10y

- 14-37y-15y

- 14-37y-20y

- 14-37y-25y

- 14-37y-30y

- 14-37y-35y

- 14-37y-40y

- 14-37y-45y

- 14-37y-50y

- 14-38y-10y

- 14-38y-15y

- 14-38y-20y

- 14-38y-25y

- 14-38y-30y

- 14-38y-35y

- 14-38y-40y

- 14-38y-45y

- 14-38y-50y

- 14-39y-10y

- 14-39y-15y

- 14-39y-20y

- 14-39y-25y

- 14-39y-30y

- 14-39y-35y

- 14-39y-40y

- 14-39y-45y

- 14-39y-50y

- 14-40y-10y

- 14-40y-15y

- 14-40y-20y

- 14-40y-25y

- 14-40y-30y

- 14-40y-35y

- 14-40y-40y

- 14-40y-45y

- 14-40y-50y

- 14-41y-10y

- 14-41y-15y

- 14-41y-20y

- 14-41y-25y

- 14-41y-30y

- 14-41y-35y

- 14-41y-40y

- 14-41y-45y

- 14-41y-50y

- 14-42y-10y

- 14-42y-15y

- 14-42y-20y

- 14-42y-25y

- 14-42y-30y

- 14-42y-35y

- 14-42y-40y

- 14-42y-45y

- 14-42y-50y

- 14-43y-10y

- 14-43y-15y

- 14-43y-20y

- 14-43y-25y

- 14-43y-30y

- 14-43y-35y

- 14-43y-40y

- 14-43y-45y

- 14-43y-50y

- 14-44y-10y

- 14-44y-15y

- 14-44y-20y

- 14-44y-25y

- 14-44y-30y

- 14-44y-35y

- 14-44y-40y

- 14-44y-45y

- 14-44y-50y

- 14-45y-10y

- 14-45y-15y

- 14-45y-20y

- 14-45y-25y

- 14-45y-30y

- 14-45y-35y

- 14-45y-40y

- 14-45y-45y

- 14-45y-50y

- 14-46y-10y

- 14-46y-15y

- 14-46y-20y

- 14-46y-25y

- 14-46y-30y

- 14-46y-35y

- 14-46y-40y

- 14-46y-45y

- 14-46y-50y

- 14-47y-10y

- 14-47y-15y

- 14-47y-20y

- 14-47y-25y

- 14-47y-30y

- 14-47y-35y

- 14-47y-40y

- 14-47y-45y

- 14-47y-50y

- 14-48y-10y

- 14-48y-15y

- 14-48y-20y

- 14-48y-25y

- 14-48y-30y

- 14-48y-35y

- 14-48y-40y

- 14-48y-45y

- 14-48y-50y

- 14-49y-10y

- 14-49y-15y

- 14-49y-20y

- 14-49y-25y

- 14-49y-30y

- 14-49y-35y

- 14-49y-40y

- 14-49y-45y

- 14-49y-50y

- 14-50y-10y

- 14-50y-15y

- 14-50y-20y

- 14-50y-25y

- 14-50y-30y

- 14-50y-35y

- 14-50y-40y

- 14-50y-45y

- 14-50y-50y

- 14-51y-10y

- 14-51y-15y

- 14-51y-20y

- 14-51y-25y

- 14-51y-30y

- 14-51y-35y

- 14-51y-40y

- 14-51y-45y

- 14-51y-50y

- 14-52y-10y

- 14-52y-15y

- 14-52y-20y

- 14-52y-25y

- 14-52y-30y

- 14-52y-35y

- 14-52y-40y

- 14-52y-45y

- 14-52y-50y

- 14-53y-10y

- 14-53y-15y

- 14-53y-20y

- 14-53y-25y

- 14-53y-30y

- 14-53y-35y

- 14-53y-40y

- 14-53y-45y

- 14-53y-50y

- 14-54y-10y

- 14-54y-15y

- 14-54y-20y

- 14-54y-25y

- 14-54y-30y

- 14-54y-35y

- 14-54y-40y

- 14-54y-45y

- 14-54y-50y

- 14-55y-10y

- 14-55y-15y

- 14-55y-20y

- 14-55y-25y

- 14-55y-30y

- 14-55y-35y

- 14-55y-40y

- 14-55y-45y

- 14-55y-50y

- 14-56y-10y

- 14-56y-15y

- 14-56y-20y

- 14-56y-25y

- 14-56y-30y

- 14-56y-35y

- 14-56y-40y

- 14-56y-45y

- 14-56y-50y

- 14-57y-10y

- 14-57y-15y

- 14-57y-20y

- 14-57y-25y

- 14-57y-30y

- 14-57y-35y

- 14-57y-40y

- 14-57y-45y

- 14-57y-50y

- 14-58y-10y

- 14-58y-15y

- 14-58y-20y

- 14-58y-25y

- 14-58y-30y

- 14-58y-35y

- 14-58y-40y

- 14-58y-45y

- 14-58y-50y

- 14-59y-10y

- 14-59y-15y

- 14-59y-20y

- 14-59y-25y

- 14-59y-30y

- 14-59y-35y

- 14-59y-40y

- 14-59y-45y

- 14-59y-50y

- 14-60y-10y

- 14-60y-15y

- 14-60y-20y

- 14-60y-25y

- 14-60y-30y

- 14-60y-35y

- 14-60y-40y

- 14-60y-45y

- 14-60y-50y

- 14-61y-10y

- 14-61y-15y

- 14-61y-20y

- 14-61y-25y

- 14-61y-30y

- 14-61y-35y

- 14-61y-40y

- 14-61y-45y

- 14-61y-50y

- 14-62y-10y

- 14-62y-15y

- 14-62y-20y

- 14-62y-25y

- 14-62y-30y

- 14-62y-35y

- 14-62y-40y

- 14-62y-45y

- 14-62y-50y

- 14-63y-10y

- 14-63y-15y

- 14-63y-20y

- 14-63y-25y

- 14-63y-30y

- 14-63y-35y

- 14-63y-40y

- 14-63y-45y

- 14-63y-50y

- 14-64y-10y

- 14-64y-15y

- 14-64y-20y

- 14-64y-25y

- 14-64y-30y

- 14-64y-35y

- 14-64y-40y

- 14-64y-45y

- 14-64y-50y

- 14-65y-10y

- 14-65y-15y

- 14-65y-20y

- 14-65y-25y

- 14-65y-30y

- 14-65y-35y

- 14-65y-40y

- 14-65y-45y

- 14-65y-50y

- 14-66y-10y

- 14-66y-15y

- 14-66y-20y

- 14-66y-25y

- 14-66y-30y

- 14-66y-35y

- 14-66y-40y

- 14-66y-45y

- 14-66y-50y

- 14-67y-10y

- 14-67y-15y

- 14-67y-20y

- 14-67y-25y

- 14-67y-30y

- 14-67y-35y

- 14-67y-40y

- 14-67y-45y

- 14-67y-50y

- 14-68y-10y

- 14-68y-15y

- 14-68y-20y

- 14-68y-25y

- 14-68y-30y

- 14-68y-35y

- 14-68y-40y

- 14-68y-45y

- 14-68y-50y

- 14-69y-10y

- 14-69y-15y

- 14-69y-20y

- 14-69y-25y

- 14-69y-30y

- 14-69y-35y

- 14-69y-40y

- 14-69y-45y

- 14-69y-50y

- 14-70y-10y

- 14-70y-15y

- 14-70y-20y

- 14-70y-25y

- 14-70y-30y

- 14-70y-35y

- 14-70y-40y

- 14-70y-45y

- 14-70y-50y

- 14-71y-10y

- 14-71y-15y

- 14-71y-20y

- 14-71y-25y

- 14-71y-30y

- 14-71y-35y

- 14-71y-40y

- 14-71y-45y

- 14-71y-50y

- 14-72y-10y

- 14-72y-15y

- 14-72y-20y

- 14-72y-25y

- 14-72y-30y

- 14-72y-35y

- 14-72y-40y

- 14-72y-45y

- 14-72y-50y

- 14-73y-10y

- 14-73y-15y

- 14-73y-20y

- 14-73y-25y

- 14-73y-30y

- 14-73y-35y

- 14-73y-40y

- 14-73y-45y

- 14-73y-50y

- 14-74y-10y

- 14-74y-15y

- 14-74y-20y

- 14-74y-25y

- 14-74y-30y

- 14-74y-35y

- 14-74y-40y

- 14-74y-45y

- 14-74y-50y

- 14-75y-10y

- 14-75y-15y

- 14-75y-20y

- 14-75y-25y

- 14-75y-30y

- 14-75y-35y

- 14-75y-40y

- 14-75y-45y

- 14-75y-50y

- 14-76y-10y

- 14-76y-15y

- 14-76y-20y

- 14-76y-25y

- 14-76y-30y

- 14-76y-35y

- 14-76y-40y

- 14-76y-45y

- 14-76y-50y

- 14-77y-10y

- 14-77y-15y

- 14-77y-20y

- 14-77y-25y

- 14-77y-30y

- 14-77y-35y

- 14-77y-40y

- 14-77y-45y

- 14-77y-50y

- 14-78y-10y

- 14-78y-15y

- 14-78y-20y

- 14-78y-25y

- 14-78y-30y

- 14-78y-35y

- 14-78y-40y

- 14-78y-45y

- 14-78y-50y

- 14-79y-10y

- 14-79y-15y

- 14-79y-20y

- 14-79y-25y

- 14-79y-30y

- 14-79y-35y

- 14-79y-40y

- 14-79y-45y

- 14-79y-50y

- 14-80y-10y

- 14-80y-15y

- 14-80y-20y

- 14-80y-25y

- 14-80y-30y

- 14-80y-35y

- 14-80y-40y

- 14-80y-45y

- 14-80y-50y

- 14-81y-10y

- 14-81y-15y

- 14-81y-20y

- 14-81y-25y

- 14-81y-30y

- 14-81y-35y

- 14-81y-40y

- 14-81y-45y

- 14-81y-50y

- 14-82y-10y

- 14-82y-15y

- 14-82y-20y

- 14-82y-25y

- 14-82y-30y

- 14-82y-35y

- 14-82y-40y

- 14-82y-45y

- 14-82y-50y

- 14-83y-10y

- 14-83y-15y

- 14-83y-20y

- 14-83y-25y

- 14-83y-30y

- 14-83y-35y

- 14-83y-40y

- 14-83y-45y

- 14-83y-50y

- 14-84y-10y

- 14-84y-15y

- 14-84y-20y

- 14-84y-25y

- 14-84y-30y

- 14-84y-35y

- 14-84y-40y

- 14-84y-45y

- 14-84y-50y

- 14-85y-10y

- 14-85y-15y

- 14-85y-20y

- 14-85y-25y

- 14-85y-30y

- 14-85y-35y

- 14-85y-40y

- 14-85y-45y

- 14-85y-50y

- 14-86y-10y

- 14-86y-15y

- 14-86y-20y

- 14-86y-25y

- 14-86y-30y

- 14-86y-35y

- 14-86y-40y

- 14-86y-45y

- 14-86y-50y

- 14-87y-10y

- 14-87y-15y

- 14-87y-20y

- 14-87y-25y

- 14-87y-30y

- 14-87y-35y

- 14-87y-40y

- 14-87y-45y

- 14-87y-50y

- 14-88y-10y

- 14-88y-15y

- 14-88y-20y

- 14-88y-25y

- 14-88y-30y

- 14-88y-35y

- 14-88y-40y

- 14-88y-45y

- 14-88y-50y

- 14-89y-10y

- 14-89y-15y

- 14-89y-20y

- 14-89y-25y

- 14-89y-30y

- 14-89y-35y

- 14-89y-40y

- 14-89y-45y

- 14-89y-50y

- 14-90y-10y

- 14-90y-15y

- 14-90y-20y

- 14-90y-25y

- 14-90y-30y

- 14-90y-35y

- 14-90y-40y

- 14-90y-45y

- 14-90y-50y

- 14-91y-10y

- 14-91y-15y

- 14-91y-20y

- 14-91y-25y

- 14-91y-30y

- 14-91y-35y

- 14-91y-40y

- 14-91y-45y

- 14-91y-50y

- 14-92y-10y

- 14-92y-15y

- 14-92y-20y

- 14-92y-25y

- 14-92y-30y

- 14-92y-35y

- 14-92y-40y

- 14-92y-45y

- 14-92y-50y

- 14-93y-10y

- 14-93y-15y

- 14-93y-20y

- 14-93y-25y

- 14-93y-30y

- 14-93y-35y

- 14-93y-40y

- 14-93y-45y

- 14-93y-50y

- 14-94y-10y

- 14-94y-15y

- 14-94y-20y

- 14-94y-25y

- 14-94y-30y

- 14-94y-35y

- 14-94y-40y

- 14-94y-45y

- 14-94y-50y

- 14-95y-10y

- 14-95y-15y

- 14-95y-20y

- 14-95y-25y

- 14-95y-30y

- 14-95y-35y

- 14-95y-40y

- 14-95y-45y

- 14-95y-50y

- 14-96y-10y

- 14-96y-15y

- 14-96y-20y

- 14-96y-25y

- 14-96y-30y

- 14-96y-35y

- 14-96y-40y

- 14-96y-45y

- 14-96y-50y

- 14-97y-10y

- 14-97y-15y

- 14-97y-20y

- 14-97y-25y

- 14-97y-30y

- 14-97y-35y

- 14-97y-40y

- 14-97y-45y

- 14-97y-50y

- 14-98y-10y

- 14-98y-15y

- 14-98y-20y

- 14-98y-25y

- 14-98y-30y

- 14-98y-35y

- 14-98y-40y

- 14-98y-45y

- 14-98y-50y

- 14-99y-10y

- 14-99y-15y

- 14-99y-20y

- 14-99y-25y

- 14-99y-30y

- 14-99y-35y

- 14-99y-40y

- 14-99y-45y

- 14-99y-50y

- 14-100y-10y

- 14-100y-15y

- 14-100y-20y

- 14-100y-25y

- 14-100y-30y

- 14-100y-35y

- 14-100y-40y

- 14-100y-45y

- 14-100y-50y

- 16-22r-10r

- 16-22r-15r

- 16-22r-20r

- 16-22r-25r

- 16-22r-30r

- 16-22r-35r

- 16-22r-40r

- 16-22r-45r

- 16-22r-50r

- 16-23r-10r

- 16-23r-15r

- 16-23r-20r

- 16-23r-25r

- 16-23r-30r

- 16-23r-35r

- 16-23r-40r

- 16-23r-45r

- 16-23r-50r

- 16-24r-10r

- 16-24r-15r

- 16-24r-20r

- 16-24r-25r

- 16-24r-30r

- 16-24r-35r

- 16-24r-40r

- 16-24r-45r

- 16-24r-50r

- 16-25r-10r

- 16-25r-15r

- 16-25r-20r

- 16-25r-25r

- 16-25r-30r

- 16-25r-35r

- 16-25r-40r

- 16-25r-45r

- 16-25r-50r

- 16-26r-10r

- 16-26r-15r

- 16-26r-20r

- 16-26r-25r

- 16-26r-30r

- 16-26r-35r

- 16-26r-40r

- 16-26r-45r

- 16-26r-50r

- 16-27r-10r

- 16-27r-15r

- 16-27r-20r

- 16-27r-25r

- 16-27r-30r

- 16-27r-35r

- 16-27r-40r

- 16-27r-45r

- 16-27r-50r

- 16-28r-10r

- 16-28r-15r

- 16-28r-20r

- 16-28r-25r

- 16-28r-30r

- 16-28r-35r

- 16-28r-40r

- 16-28r-45r

- 16-28r-50r

- 16-29r-10r

- 16-29r-15r

- 16-29r-20r

- 16-29r-25r

- 16-29r-30r

- 16-29r-35r

- 16-29r-40r

- 16-29r-45r

- 16-29r-50r

- 16-30r-10r

- 16-30r-15r

- 16-30r-20r

- 16-30r-25r

- 16-30r-30r

- 16-30r-35r

- 16-30r-40r

- 16-30r-45r

- 16-30r-50r

- 16-31r-10r

- 16-31r-15r

- 16-31r-20r

- 16-31r-25r

- 16-31r-30r

- 16-31r-35r

- 16-31r-40r

- 16-31r-45r

- 16-31r-50r

- 16-32r-10r

- 16-32r-15r

- 16-32r-20r

- 16-32r-25r

- 16-32r-30r

- 16-32r-35r

- 16-32r-40r

- 16-32r-45r

- 16-32r-50r

- 16-33r-10r

- 16-33r-15r

- 16-33r-20r

- 16-33r-25r

- 16-33r-30r

- 16-33r-35r

- 16-33r-40r

- 16-33r-45r

- 16-33r-50r

- 16-34r-10r

- 16-34r-15r

- 16-34r-20r

- 16-34r-25r

- 16-34r-30r

- 16-34r-35r

- 16-34r-40r

- 16-34r-45r

- 16-34r-50r

- 16-35r-10r

- 16-35r-15r

- 16-35r-20r

- 16-35r-25r

- 16-35r-30r

- 16-35r-35r

- 16-35r-40r

- 16-35r-45r

- 16-35r-50r

- 16-36r-10r

- 16-36r-15r

- 16-36r-20r

- 16-36r-25r

- 16-36r-30r

- 16-36r-35r

- 16-36r-40r

- 16-36r-45r

- 16-36r-50r

- 16-37r-10r

- 16-37r-15r

- 16-37r-20r

- 16-37r-25r

- 16-37r-30r

- 16-37r-35r

- 16-37r-40r

- 16-37r-45r

- 16-37r-50r

- 16-38r-10r

- 16-38r-15r

- 16-38r-20r

- 16-38r-25r

- 16-38r-30r

- 16-38r-35r

- 16-38r-40r

- 16-38r-45r

- 16-38r-50r

- 16-39r-10r

- 16-39r-15r

- 16-39r-20r

- 16-39r-25r

- 16-39r-30r

- 16-39r-35r

- 16-39r-40r

- 16-39r-45r

- 16-39r-50r

- 16-40r-10r

- 16-40r-15r

- 16-40r-20r

- 16-40r-25r

- 16-40r-30r

- 16-40r-35r

- 16-40r-40r

- 16-40r-45r

- 16-40r-50r

- 16-41r-10r

- 16-41r-15r

- 16-41r-20r

- 16-41r-25r

- 16-41r-30r

- 16-41r-35r

- 16-41r-40r

- 16-41r-45r

- 16-41r-50r

- 16-42r-10r

- 16-42r-15r

- 16-42r-20r

- 16-42r-25r

- 16-42r-30r

- 16-42r-35r

- 16-42r-40r

- 16-42r-45r

- 16-42r-50r

- 16-43r-10r

- 16-43r-15r

- 16-43r-20r

- 16-43r-25r

- 16-43r-30r

- 16-43r-35r

- 16-43r-40r

- 16-43r-45r

- 16-43r-50r

- 16-44r-10r

- 16-44r-15r

- 16-44r-20r

- 16-44r-25r

- 16-44r-30r

- 16-44r-35r

- 16-44r-40r

- 16-44r-45r

- 16-44r-50r

- 16-45r-10r

- 16-45r-15r

- 16-45r-20r

- 16-45r-25r

- 16-45r-30r

- 16-45r-35r

- 16-45r-40r

- 16-45r-45r

- 16-45r-50r

- 16-46r-10r

- 16-46r-15r

- 16-46r-20r

- 16-46r-25r

- 16-46r-30r

- 16-46r-35r

- 16-46r-40r

- 16-46r-45r

- 16-46r-50r

- 16-47r-10r

- 16-47r-15r

- 16-47r-20r

- 16-47r-25r

- 16-47r-30r

- 16-47r-35r

- 16-47r-40r

- 16-47r-45r

- 16-47r-50r

- 16-48r-10r

- 16-48r-15r

- 16-48r-20r

- 16-48r-25r

- 16-48r-30r

- 16-48r-35r

- 16-48r-40r

- 16-48r-45r

- 16-48r-50r

- 16-49r-10r

- 16-49r-15r

- 16-49r-20r

- 16-49r-25r

- 16-49r-30r

- 16-49r-35r

- 16-49r-40r

- 16-49r-45r

- 16-49r-50r

- 16-50r-10r

- 16-50r-15r

- 16-50r-20r

- 16-50r-25r

- 16-50r-30r

- 16-50r-35r

- 16-50r-40r

- 16-50r-45r

- 16-50r-50r

- 16-51r-10r

- 16-51r-15r

- 16-51r-20r

- 16-51r-25r

- 16-51r-30r

- 16-51r-35r

- 16-51r-40r

- 16-51r-45r

- 16-51r-50r

- 16-52r-10r

- 16-52r-15r

- 16-52r-20r

- 16-52r-25r

- 16-52r-30r

- 16-52r-35r

- 16-52r-40r

- 16-52r-45r

- 16-52r-50r

- 16-53r-10r

- 16-53r-15r

- 16-53r-20r

- 16-53r-25r

- 16-53r-30r

- 16-53r-35r

- 16-53r-40r

- 16-53r-45r

- 16-53r-50r

- 16-54r-10r

- 16-54r-15r

- 16-54r-20r

- 16-54r-25r

- 16-54r-30r

- 16-54r-35r

- 16-54r-40r

- 16-54r-45r

- 16-54r-50r

- 16-55r-10r

- 16-55r-15r

- 16-55r-20r

- 16-55r-25r

- 16-55r-30r

- 16-55r-35r

- 16-55r-40r

- 16-55r-45r

- 16-55r-50r

- 16-56r-10r

- 16-56r-15r

- 16-56r-20r

- 16-56r-25r

- 16-56r-30r

- 16-56r-35r

- 16-56r-40r

- 16-56r-45r

- 16-56r-50r

- 16-57r-10r

- 16-57r-15r

- 16-57r-20r

- 16-57r-25r

- 16-57r-30r

- 16-57r-35r

- 16-57r-40r

- 16-57r-45r

- 16-57r-50r

- 16-58r-10r

- 16-58r-15r

- 16-58r-20r

- 16-58r-25r

- 16-58r-30r

- 16-58r-35r

- 16-58r-40r

- 16-58r-45r

- 16-58r-50r

- 16-59r-10r

- 16-59r-15r

- 16-59r-20r

- 16-59r-25r

- 16-59r-30r

- 16-59r-35r

- 16-59r-40r

- 16-59r-45r

- 16-59r-50r

- 16-60r-10r

- 16-60r-15r

- 16-60r-20r

- 16-60r-25r

- 16-60r-30r

- 16-60r-35r

- 16-60r-40r

- 16-60r-45r

- 16-60r-50r

- 16-61r-10r

- 16-61r-15r

- 16-61r-20r

- 16-61r-25r

- 16-61r-30r

- 16-61r-35r

- 16-61r-40r

- 16-61r-45r

- 16-61r-50r

- 16-62r-10r

- 16-62r-15r

- 16-62r-20r

- 16-62r-25r

- 16-62r-30r

- 16-62r-35r

- 16-62r-40r

- 16-62r-45r

- 16-62r-50r

- 16-63r-10r

- 16-63r-15r

- 16-63r-20r

- 16-63r-25r

- 16-63r-30r

- 16-63r-35r

- 16-63r-40r

- 16-63r-45r

- 16-63r-50r

- 16-64r-10r

- 16-64r-15r

- 16-64r-20r

- 16-64r-25r

- 16-64r-30r

- 16-64r-35r

- 16-64r-40r

- 16-64r-45r

- 16-64r-50r

- 16-65r-10r

- 16-65r-15r

- 16-65r-20r

- 16-65r-25r

- 16-65r-30r

- 16-65r-35r

- 16-65r-40r

- 16-65r-45r

- 16-65r-50r

- 16-66r-10r

- 16-66r-15r

- 16-66r-20r

- 16-66r-25r

- 16-66r-30r

- 16-66r-35r

- 16-66r-40r

- 16-66r-45r

- 16-66r-50r

- 16-67r-10r

- 16-67r-15r

- 16-67r-20r

- 16-67r-25r

- 16-67r-30r

- 16-67r-35r

- 16-67r-40r

- 16-67r-45r

- 16-67r-50r

- 16-68r-10r

- 16-68r-15r

- 16-68r-20r

- 16-68r-25r

- 16-68r-30r

- 16-68r-35r

- 16-68r-40r

- 16-68r-45r

- 16-68r-50r

- 16-69r-10r

- 16-69r-15r

- 16-69r-20r

- 16-69r-25r

- 16-69r-30r

- 16-69r-35r

- 16-69r-40r

- 16-69r-45r

- 16-69r-50r

- 16-70r-10r

- 16-70r-15r

- 16-70r-20r

- 16-70r-25r

- 16-70r-30r

- 16-70r-35r

- 16-70r-40r

- 16-70r-45r

- 16-70r-50r

- 16-71r-10r

- 16-71r-15r

- 16-71r-20r

- 16-71r-25r

- 16-71r-30r

- 16-71r-35r

- 16-71r-40r

- 16-71r-45r

- 16-71r-50r

- 16-72r-10r

- 16-72r-15r

- 16-72r-20r

- 16-72r-25r

- 16-72r-30r

- 16-72r-35r

- 16-72r-40r

- 16-72r-45r

- 16-72r-50r

- 16-73r-10r

- 16-73r-15r

- 16-73r-20r

- 16-73r-25r

- 16-73r-30r

- 16-73r-35r

- 16-73r-40r

- 16-73r-45r

- 16-73r-50r

- 16-74r-10r

- 16-74r-15r

- 16-74r-20r

- 16-74r-25r

- 16-74r-30r

- 16-74r-35r

- 16-74r-40r

- 16-74r-45r

- 16-74r-50r

- 16-75r-10r

- 16-75r-15r

- 16-75r-20r

- 16-75r-25r

- 16-75r-30r

- 16-75r-35r

- 16-75r-40r

- 16-75r-45r

- 16-75r-50r

- 16-76r-10r

- 16-76r-15r

- 16-76r-20r

- 16-76r-25r

- 16-76r-30r

- 16-76r-35r

- 16-76r-40r

- 16-76r-45r

- 16-76r-50r

- 16-77r-10r

- 16-77r-15r

- 16-77r-20r

- 16-77r-25r

- 16-77r-30r

- 16-77r-35r

- 16-77r-40r

- 16-77r-45r

- 16-77r-50r

- 16-78r-10r

- 16-78r-15r

- 16-78r-20r

- 16-78r-25r

- 16-78r-30r

- 16-78r-35r

- 16-78r-40r

- 16-78r-45r

- 16-78r-50r

- 16-79r-10r

- 16-79r-15r

- 16-79r-20r

- 16-79r-25r

- 16-79r-30r

- 16-79r-35r

- 16-79r-40r

- 16-79r-45r

- 16-79r-50r

- 16-80r-10r

- 16-80r-15r

- 16-80r-20r

- 16-80r-25r

- 16-80r-30r

- 16-80r-35r

- 16-80r-40r

- 16-80r-45r

- 16-80r-50r

- 16-81r-10r

- 16-81r-15r

- 16-81r-20r

- 16-81r-25r

- 16-81r-30r

- 16-81r-35r

- 16-81r-40r

- 16-81r-45r

- 16-81r-50r

- 16-82r-10r

- 16-82r-15r

- 16-82r-20r

- 16-82r-25r

- 16-82r-30r

- 16-82r-35r

- 16-82r-40r

- 16-82r-45r

- 16-82r-50r

- 16-83r-10r

- 16-83r-15r

- 16-83r-20r

- 16-83r-25r

- 16-83r-30r

- 16-83r-35r

- 16-83r-40r

- 16-83r-45r

- 16-83r-50r

- 16-84r-10r

- 16-84r-15r

- 16-84r-20r

- 16-84r-25r

- 16-84r-30r

- 16-84r-35r

- 16-84r-40r

- 16-84r-45r

- 16-84r-50r

- 16-85r-10r

- 16-85r-15r

- 16-85r-20r

- 16-85r-25r

- 16-85r-30r

- 16-85r-35r

- 16-85r-40r

- 16-85r-45r

- 16-85r-50r

- 16-86r-10r

- 16-86r-15r

- 16-86r-20r

- 16-86r-25r

- 16-86r-30r

- 16-86r-35r

- 16-86r-40r

- 16-86r-45r

- 16-86r-50r

- 16-87r-10r

- 16-87r-15r

- 16-87r-20r

- 16-87r-25r

- 16-87r-30r

- 16-87r-35r

- 16-87r-40r

- 16-87r-45r

- 16-87r-50r

- 16-88r-10r

- 16-88r-15r

- 16-88r-20r

- 16-88r-25r

- 16-88r-30r

- 16-88r-35r

- 16-88r-40r

- 16-88r-45r

- 16-88r-50r

- 16-89r-10r

- 16-89r-15r

- 16-89r-20r

- 16-89r-25r

- 16-89r-30r

- 16-89r-35r

- 16-89r-40r

- 16-89r-45r

- 16-89r-50r

- 16-90r-10r

- 16-90r-15r

- 16-90r-20r

- 16-90r-25r

- 16-90r-30r

- 16-90r-35r

- 16-90r-40r

- 16-90r-45r

- 16-90r-50r

- 16-91r-10r

- 16-91r-15r

- 16-91r-20r

- 16-91r-25r

- 16-91r-30r

- 16-91r-35r

- 16-91r-40r

- 16-91r-45r

- 16-91r-50r

- 16-92r-10r

- 16-92r-15r

- 16-92r-20r

- 16-92r-25r

- 16-92r-30r

- 16-92r-35r

- 16-92r-40r

- 16-92r-45r

- 16-92r-50r

- 16-93r-10r

- 16-93r-15r

- 16-93r-20r

- 16-93r-25r

- 16-93r-30r

- 16-93r-35r

- 16-93r-40r

- 16-93r-45r

- 16-93r-50r

- 16-94r-10r

- 16-94r-15r

- 16-94r-20r

- 16-94r-25r

- 16-94r-30r

- 16-94r-35r

- 16-94r-40r

- 16-94r-45r

- 16-94r-50r

- 16-95r-10r

- 16-95r-15r

- 16-95r-20r

- 16-95r-25r

- 16-95r-30r

- 16-95r-35r

- 16-95r-40r

- 16-95r-45r

- 16-95r-50r

- 16-96r-10r

- 16-96r-15r

- 16-96r-20r

- 16-96r-25r

- 16-96r-30r

- 16-96r-35r

- 16-96r-40r

- 16-96r-45r

- 16-96r-50r

- 16-97r-10r

- 16-97r-15r

- 16-97r-20r

- 16-97r-25r

- 16-97r-30r

- 16-97r-35r

- 16-97r-40r

- 16-97r-45r

- 16-97r-50r

- 16-98r-10r

- 16-98r-15r

- 16-98r-20r

- 16-98r-25r

- 16-98r-30r

- 16-98r-35r

- 16-98r-40r

- 16-98r-45r

- 16-98r-50r

- 16-99r-10r

- 16-99r-15r

- 16-99r-20r

- 16-99r-25r

- 16-99r-30r

- 16-99r-35r

- 16-99r-40r

- 16-99r-45r

- 16-99r-50r

- 16-100r-10r

- 16-100r-15r

- 16-100r-20r

- 16-100r-25r

- 16-100r-30r

- 16-100r-35r

- 16-100r-40r

- 16-100r-45r

- 16-100r-50r

- 16-22y-10y

- 16-22y-15y

- 16-22y-20y

- 16-22y-25y

- 16-22y-30y

- 16-22y-35y

- 16-22y-40y

- 16-22y-45y

- 16-22y-50y

- 16-23y-10y

- 16-23y-15y

- 16-23y-20y

- 16-23y-25y

- 16-23y-30y

- 16-23y-35y

- 16-23y-40y

- 16-23y-45y

- 16-23y-50y

- 16-24y-10y

- 16-24y-15y

- 16-24y-20y

- 16-24y-25y

- 16-24y-30y

- 16-24y-35y

- 16-24y-40y

- 16-24y-45y

- 16-24y-50y

- 16-25y-10y

- 16-25y-15y

- 16-25y-20y

- 16-25y-25y

- 16-25y-30y

- 16-25y-35y

- 16-25y-40y

- 16-25y-45y

- 16-25y-50y

- 16-26y-10y

- 16-26y-15y

- 16-26y-20y

- 16-26y-25y

- 16-26y-30y

- 16-26y-35y

- 16-26y-40y

- 16-26y-45y

- 16-26y-50y

- 16-27y-10y

- 16-27y-15y

- 16-27y-20y

- 16-27y-25y

- 16-27y-30y

- 16-27y-35y

- 16-27y-40y

- 16-27y-45y

- 16-27y-50y

- 16-28y-10y

- 16-28y-15y

- 16-28y-20y

- 16-28y-25y

- 16-28y-30y

- 16-28y-35y

- 16-28y-40y

- 16-28y-45y

- 16-28y-50y

- 16-29y-10y

- 16-29y-15y

- 16-29y-20y

- 16-29y-25y

- 16-29y-30y

- 16-29y-35y

- 16-29y-40y

- 16-29y-45y

- 16-29y-50y

- 16-30y-10y

- 16-30y-15y

- 16-30y-20y

- 16-30y-25y

- 16-30y-30y

- 16-30y-35y

- 16-30y-40y

- 16-30y-45y

- 16-30y-50y

- 16-31y-10y

- 16-31y-15y

- 16-31y-20y

- 16-31y-25y

- 16-31y-30y

- 16-31y-35y

- 16-31y-40y

- 16-31y-45y

- 16-31y-50y

- 16-32y-10y

- 16-32y-15y

- 16-32y-20y

- 16-32y-25y

- 16-32y-30y

- 16-32y-35y

- 16-32y-40y

- 16-32y-45y

- 16-32y-50y

- 16-33y-10y

- 16-33y-15y

- 16-33y-20y

- 16-33y-25y

- 16-33y-30y

- 16-33y-35y

- 16-33y-40y

- 16-33y-45y

- 16-33y-50y

- 16-34y-10y

- 16-34y-15y

- 16-34y-20y

- 16-34y-25y

- 16-34y-30y

- 16-34y-35y

- 16-34y-40y

- 16-34y-45y

- 16-34y-50y

- 16-35y-10y

- 16-35y-15y

- 16-35y-20y

- 16-35y-25y

- 16-35y-30y

- 16-35y-35y

- 16-35y-40y

- 16-35y-45y

- 16-35y-50y

- 16-36y-10y

- 16-36y-15y

- 16-36y-20y

- 16-36y-25y

- 16-36y-30y

- 16-36y-35y

- 16-36y-40y

- 16-36y-45y

- 16-36y-50y

- 16-37y-10y

- 16-37y-15y

- 16-37y-20y

- 16-37y-25y

- 16-37y-30y

- 16-37y-35y

- 16-37y-40y

- 16-37y-45y

- 16-37y-50y

- 16-38y-10y

- 16-38y-15y

- 16-38y-20y

- 16-38y-25y

- 16-38y-30y

- 16-38y-35y

- 16-38y-40y

- 16-38y-45y

- 16-38y-50y

- 16-39y-10y

- 16-39y-15y

- 16-39y-20y

- 16-39y-25y

- 16-39y-30y

- 16-39y-35y

- 16-39y-40y

- 16-39y-45y

- 16-39y-50y

- 16-40y-10y

- 16-40y-15y

- 16-40y-20y

- 16-40y-25y

- 16-40y-30y

- 16-40y-35y

- 16-40y-40y

- 16-40y-45y

- 16-40y-50y

- 16-41y-10y

- 16-41y-15y

- 16-41y-20y

- 16-41y-25y

- 16-41y-30y

- 16-41y-35y

- 16-41y-40y

- 16-41y-45y

- 16-41y-50y

- 16-42y-10y

- 16-42y-15y

- 16-42y-20y

- 16-42y-25y

- 16-42y-30y

- 16-42y-35y

- 16-42y-40y

- 16-42y-45y

- 16-42y-50y

- 16-43y-10y

- 16-43y-15y

- 16-43y-20y

- 16-43y-25y

- 16-43y-30y

- 16-43y-35y

- 16-43y-40y

- 16-43y-45y

- 16-43y-50y

- 16-44y-10y

- 16-44y-15y

- 16-44y-20y

- 16-44y-25y

- 16-44y-30y

- 16-44y-35y

- 16-44y-40y

- 16-44y-45y

- 16-44y-50y

- 16-45y-10y

- 16-45y-15y

- 16-45y-20y

- 16-45y-25y

- 16-45y-30y

- 16-45y-35y

- 16-45y-40y

- 16-45y-45y

- 16-45y-50y

- 16-46y-10y

- 16-46y-15y

- 16-46y-20y

- 16-46y-25y

- 16-46y-30y

- 16-46y-35y

- 16-46y-40y

- 16-46y-45y

- 16-46y-50y

- 16-47y-10y

- 16-47y-15y

- 16-47y-20y

- 16-47y-25y

- 16-47y-30y

- 16-47y-35y

- 16-47y-40y

- 16-47y-45y

- 16-47y-50y

- 16-48y-10y

- 16-48y-15y

- 16-48y-20y

- 16-48y-25y

- 16-48y-30y

- 16-48y-35y

- 16-48y-40y

- 16-48y-45y

- 16-48y-50y

- 16-49y-10y

- 16-49y-15y

- 16-49y-20y

- 16-49y-25y

- 16-49y-30y

- 16-49y-35y

- 16-49y-40y

- 16-49y-45y

- 16-49y-50y

- 16-50y-10y

- 16-50y-15y

- 16-50y-20y

- 16-50y-25y

- 16-50y-30y

- 16-50y-35y

- 16-50y-40y

- 16-50y-45y

- 16-50y-50y

- 16-51y-10y

- 16-51y-15y

- 16-51y-20y

- 16-51y-25y

- 16-51y-30y

- 16-51y-35y

- 16-51y-40y

- 16-51y-45y

- 16-51y-50y

- 16-52y-10y

- 16-52y-15y

- 16-52y-20y

- 16-52y-25y

- 16-52y-30y

- 16-52y-35y

- 16-52y-40y

- 16-52y-45y

- 16-52y-50y

- 16-53y-10y

- 16-53y-15y

- 16-53y-20y

- 16-53y-25y

- 16-53y-30y

- 16-53y-35y

- 16-53y-40y

- 16-53y-45y

- 16-53y-50y

- 16-54y-10y

- 16-54y-15y

- 16-54y-20y

- 16-54y-25y

- 16-54y-30y

- 16-54y-35y

- 16-54y-40y

- 16-54y-45y

- 16-54y-50y

- 16-55y-10y

- 16-55y-15y

- 16-55y-20y

- 16-55y-25y

- 16-55y-30y

- 16-55y-35y

- 16-55y-40y

- 16-55y-45y

- 16-55y-50y

- 16-56y-10y

- 16-56y-15y

- 16-56y-20y

- 16-56y-25y

- 16-56y-30y

- 16-56y-35y

- 16-56y-40y

- 16-56y-45y

- 16-56y-50y

- 16-57y-10y

- 16-57y-15y

- 16-57y-20y

- 16-57y-25y

- 16-57y-30y

- 16-57y-35y

- 16-57y-40y

- 16-57y-45y

- 16-57y-50y

- 16-58y-10y

- 16-58y-15y

- 16-58y-20y

- 16-58y-25y

- 16-58y-30y

- 16-58y-35y

- 16-58y-40y

- 16-58y-45y

- 16-58y-50y

- 16-59y-10y

- 16-59y-15y

- 16-59y-20y

- 16-59y-25y

- 16-59y-30y

- 16-59y-35y

- 16-59y-40y

- 16-59y-45y

- 16-59y-50y

- 16-60y-10y

- 16-60y-15y

- 16-60y-20y

- 16-60y-25y

- 16-60y-30y

- 16-60y-35y

- 16-60y-40y

- 16-60y-45y

- 16-60y-50y

- 16-61y-10y

- 16-61y-15y

- 16-61y-20y

- 16-61y-25y

- 16-61y-30y

- 16-61y-35y

- 16-61y-40y

- 16-61y-45y

- 16-61y-50y

- 16-62y-10y

- 16-62y-15y

- 16-62y-20y

- 16-62y-25y

- 16-62y-30y

- 16-62y-35y

- 16-62y-40y

- 16-62y-45y

- 16-62y-50y

- 16-63y-10y

- 16-63y-15y

- 16-63y-20y

- 16-63y-25y

- 16-63y-30y

- 16-63y-35y

- 16-63y-40y

- 16-63y-45y

- 16-63y-50y

- 16-64y-10y

- 16-64y-15y

- 16-64y-20y

- 16-64y-25y

- 16-64y-30y

- 16-64y-35y

- 16-64y-40y

- 16-64y-45y

- 16-64y-50y

- 16-65y-10y

- 16-65y-15y

- 16-65y-20y

- 16-65y-25y

- 16-65y-30y

- 16-65y-35y

- 16-65y-40y

- 16-65y-45y

- 16-65y-50y

- 16-66y-10y

- 16-66y-15y

- 16-66y-20y

- 16-66y-25y

- 16-66y-30y

- 16-66y-35y

- 16-66y-40y

- 16-66y-45y

- 16-66y-50y

- 16-67y-10y

- 16-67y-15y

- 16-67y-20y

- 16-67y-25y

- 16-67y-30y

- 16-67y-35y

- 16-67y-40y

- 16-67y-45y

- 16-67y-50y

- 16-68y-10y

- 16-68y-15y

- 16-68y-20y

- 16-68y-25y

- 16-68y-30y

- 16-68y-35y

- 16-68y-40y

- 16-68y-45y

- 16-68y-50y

- 16-69y-10y

- 16-69y-15y

- 16-69y-20y

- 16-69y-25y

- 16-69y-30y

- 16-69y-35y

- 16-69y-40y

- 16-69y-45y

- 16-69y-50y

- 16-70y-10y

- 16-70y-15y

- 16-70y-20y

- 16-70y-25y

- 16-70y-30y

- 16-70y-35y

- 16-70y-40y

- 16-70y-45y

- 16-70y-50y

- 16-71y-10y

- 16-71y-15y

- 16-71y-20y

- 16-71y-25y

- 16-71y-30y

- 16-71y-35y

- 16-71y-40y

- 16-71y-45y

- 16-71y-50y

- 16-72y-10y

- 16-72y-15y

- 16-72y-20y

- 16-72y-25y

- 16-72y-30y

- 16-72y-35y

- 16-72y-40y

- 16-72y-45y

- 16-72y-50y

- 16-73y-10y

- 16-73y-15y

- 16-73y-20y

- 16-73y-25y

- 16-73y-30y

- 16-73y-35y

- 16-73y-40y

- 16-73y-45y

- 16-73y-50y

- 16-74y-10y

- 16-74y-15y

- 16-74y-20y

- 16-74y-25y

- 16-74y-30y

- 16-74y-35y

- 16-74y-40y

- 16-74y-45y

- 16-74y-50y

- 16-75y-10y

- 16-75y-15y

- 16-75y-20y

- 16-75y-25y

- 16-75y-30y

- 16-75y-35y

- 16-75y-40y

- 16-75y-45y

- 16-75y-50y

- 16-76y-10y

- 16-76y-15y

- 16-76y-20y

- 16-76y-25y

- 16-76y-30y

- 16-76y-35y

- 16-76y-40y

- 16-76y-45y

- 16-76y-50y

- 16-77y-10y

- 16-77y-15y

- 16-77y-20y

- 16-77y-25y

- 16-77y-30y

- 16-77y-35y

- 16-77y-40y

- 16-77y-45y

- 16-77y-50y

- 16-78y-10y

- 16-78y-15y

- 16-78y-20y

- 16-78y-25y

- 16-78y-30y

- 16-78y-35y

- 16-78y-40y

- 16-78y-45y

- 16-78y-50y

- 16-79y-10y

- 16-79y-15y

- 16-79y-20y

- 16-79y-25y

- 16-79y-30y

- 16-79y-35y

- 16-79y-40y

- 16-79y-45y

- 16-79y-50y

- 16-80y-10y

- 16-80y-15y

- 16-80y-20y

- 16-80y-25y

- 16-80y-30y

- 16-80y-35y

- 16-80y-40y

- 16-80y-45y

- 16-80y-50y

- 16-81y-10y

- 16-81y-15y

- 16-81y-20y

- 16-81y-25y

- 16-81y-30y

- 16-81y-35y

- 16-81y-40y

- 16-81y-45y

- 16-81y-50y

- 16-82y-10y

- 16-82y-15y

- 16-82y-20y

- 16-82y-25y

- 16-82y-30y

- 16-82y-35y

- 16-82y-40y

- 16-82y-45y

- 16-82y-50y

- 16-83y-10y

- 16-83y-15y

- 16-83y-20y

- 16-83y-25y

- 16-83y-30y

- 16-83y-35y

- 16-83y-40y

- 16-83y-45y

- 16-83y-50y

- 16-84y-10y

- 16-84y-15y

- 16-84y-20y

- 16-84y-25y

- 16-84y-30y

- 16-84y-35y

- 16-84y-40y

- 16-84y-45y

- 16-84y-50y

- 16-85y-10y

- 16-85y-15y

- 16-85y-20y

- 16-85y-25y

- 16-85y-30y

- 16-85y-35y

- 16-85y-40y

- 16-85y-45y

- 16-85y-50y

- 16-86y-10y

- 16-86y-15y

- 16-86y-20y

- 16-86y-25y

- 16-86y-30y

- 16-86y-35y

- 16-86y-40y

- 16-86y-45y

- 16-86y-50y

- 16-87y-10y

- 16-87y-15y

- 16-87y-20y

- 16-87y-25y

- 16-87y-30y

- 16-87y-35y

- 16-87y-40y

- 16-87y-45y

- 16-87y-50y

- 16-88y-10y

- 16-88y-15y

- 16-88y-20y

- 16-88y-25y

- 16-88y-30y

- 16-88y-35y

- 16-88y-40y

- 16-88y-45y

- 16-88y-50y

- 16-89y-10y

- 16-89y-15y

- 16-89y-20y

- 16-89y-25y

- 16-89y-30y

- 16-89y-35y

- 16-89y-40y

- 16-89y-45y

- 16-89y-50y

- 16-90y-10y

- 16-90y-15y

- 16-90y-20y

- 16-90y-25y

- 16-90y-30y

- 16-90y-35y

- 16-90y-40y

- 16-90y-45y

- 16-90y-50y

- 16-91y-10y

- 16-91y-15y

- 16-91y-20y

- 16-91y-25y

- 16-91y-30y

- 16-91y-35y

- 16-91y-40y

- 16-91y-45y

- 16-91y-50y

- 16-92y-10y

- 16-92y-15y

- 16-92y-20y

- 16-92y-25y

- 16-92y-30y

- 16-92y-35y

- 16-92y-40y

- 16-92y-45y

- 16-92y-50y

- 16-93y-10y

- 16-93y-15y

- 16-93y-20y

- 16-93y-25y

- 16-93y-30y

- 16-93y-35y

- 16-93y-40y

- 16-93y-45y

- 16-93y-50y

- 16-94y-10y

- 16-94y-15y

- 16-94y-20y

- 16-94y-25y

- 16-94y-30y

- 16-94y-35y

- 16-94y-40y

- 16-94y-45y

- 16-94y-50y

- 16-95y-10y

- 16-95y-15y

- 16-95y-20y

- 16-95y-25y

- 16-95y-30y

- 16-95y-35y

- 16-95y-40y

- 16-95y-45y

- 16-95y-50y

- 16-96y-10y

- 16-96y-15y

- 16-96y-20y

- 16-96y-25y

- 16-96y-30y

- 16-96y-35y

- 16-96y-40y

- 16-96y-45y

- 16-96y-50y

- 16-97y-10y

- 16-97y-15y

- 16-97y-20y

- 16-97y-25y

- 16-97y-30y

- 16-97y-35y

- 16-97y-40y

- 16-97y-45y

- 16-97y-50y

- 16-98y-10y

- 16-98y-15y

- 16-98y-20y

- 16-98y-25y

- 16-98y-30y

- 16-98y-35y

- 16-98y-40y

- 16-98y-45y

- 16-98y-50y

- 16-99y-10y

- 16-99y-15y

- 16-99y-20y

- 16-99y-25y

- 16-99y-30y

- 16-99y-35y

- 16-99y-40y

- 16-99y-45y

- 16-99y-50y

- 16-100y-10y

- 16-100y-15y

- 16-100y-20y

- 16-100y-25y

- 16-100y-30y

- 16-100y-35y

- 16-100y-40y

- 16-100y-45y

- 16-100y-50y

- 18-22r-10r

- 18-22r-15r

- 18-22r-20r

- 18-22r-25r

- 18-22r-30r

- 18-22r-35r

- 18-22r-40r

- 18-22r-45r

- 18-22r-50r

- 18-23r-10r

- 18-23r-15r

- 18-23r-20r

- 18-23r-25r

- 18-23r-30r

- 18-23r-35r

- 18-23r-40r

- 18-23r-45r

- 18-23r-50r

- 18-24r-10r

- 18-24r-15r

- 18-24r-20r

- 18-24r-25r

- 18-24r-30r

- 18-24r-35r

- 18-24r-40r

- 18-24r-45r

- 18-24r-50r

- 18-25r-10r

- 18-25r-15r

- 18-25r-20r

- 18-25r-25r

- 18-25r-30r

- 18-25r-35r

- 18-25r-40r

- 18-25r-45r

- 18-25r-50r

- 18-26r-10r

- 18-26r-15r

- 18-26r-20r

- 18-26r-25r

- 18-26r-30r

- 18-26r-35r

- 18-26r-40r

- 18-26r-45r

- 18-26r-50r

- 18-27r-10r

- 18-27r-15r

- 18-27r-20r

- 18-27r-25r

- 18-27r-30r

- 18-27r-35r

- 18-27r-40r

- 18-27r-45r

- 18-27r-50r

- 18-28r-10r

- 18-28r-15r

- 18-28r-20r

- 18-28r-25r

- 18-28r-30r

- 18-28r-35r

- 18-28r-40r

- 18-28r-45r

- 18-28r-50r

- 18-29r-10r

- 18-29r-15r

- 18-29r-20r

- 18-29r-25r

- 18-29r-30r

- 18-29r-35r

- 18-29r-40r

- 18-29r-45r

- 18-29r-50r

- 18-30r-10r

- 18-30r-15r

- 18-30r-20r

- 18-30r-25r

- 18-30r-30r

- 18-30r-35r

- 18-30r-40r

- 18-30r-45r

- 18-30r-50r

- 18-31r-10r

- 18-31r-15r

- 18-31r-20r

- 18-31r-25r

- 18-31r-30r

- 18-31r-35r

- 18-31r-40r

- 18-31r-45r

- 18-31r-50r

- 18-32r-10r

- 18-32r-15r

- 18-32r-20r

- 18-32r-25r

- 18-32r-30r

- 18-32r-35r

- 18-32r-40r

- 18-32r-45r

- 18-32r-50r

- 18-33r-10r

- 18-33r-15r

- 18-33r-20r

- 18-33r-25r

- 18-33r-30r

- 18-33r-35r

- 18-33r-40r

- 18-33r-45r

- 18-33r-50r

- 18-34r-10r

- 18-34r-15r

- 18-34r-20r

- 18-34r-25r

- 18-34r-30r

- 18-34r-35r

- 18-34r-40r

- 18-34r-45r

- 18-34r-50r

- 18-35r-10r

- 18-35r-15r

- 18-35r-20r

- 18-35r-25r

- 18-35r-30r

- 18-35r-35r

- 18-35r-40r

- 18-35r-45r

- 18-35r-50r

- 18-36r-10r

- 18-36r-15r

- 18-36r-20r

- 18-36r-25r

- 18-36r-30r

- 18-36r-35r

- 18-36r-40r

- 18-36r-45r

- 18-36r-50r

- 18-37r-10r

- 18-37r-15r

- 18-37r-20r

- 18-37r-25r

- 18-37r-30r

- 18-37r-35r

- 18-37r-40r

- 18-37r-45r

- 18-37r-50r

- 18-38r-10r

- 18-38r-15r

- 18-38r-20r

- 18-38r-25r

- 18-38r-30r

- 18-38r-35r

- 18-38r-40r

- 18-38r-45r

- 18-38r-50r

- 18-39r-10r

- 18-39r-15r

- 18-39r-20r

- 18-39r-25r

- 18-39r-30r

- 18-39r-35r

- 18-39r-40r

- 18-39r-45r

- 18-39r-50r

- 18-40r-10r

- 18-40r-15r

- 18-40r-20r

- 18-40r-25r

- 18-40r-30r

- 18-40r-35r

- 18-40r-40r

- 18-40r-45r

- 18-40r-50r

- 18-41r-10r

- 18-41r-15r

- 18-41r-20r

- 18-41r-25r

- 18-41r-30r

- 18-41r-35r

- 18-41r-40r

- 18-41r-45r

- 18-41r-50r

- 18-42r-10r

- 18-42r-15r

- 18-42r-20r

- 18-42r-25r

- 18-42r-30r

- 18-42r-35r

- 18-42r-40r

- 18-42r-45r

- 18-42r-50r

- 18-43r-10r

- 18-43r-15r

- 18-43r-20r

- 18-43r-25r

- 18-43r-30r

- 18-43r-35r

- 18-43r-40r

- 18-43r-45r

- 18-43r-50r

- 18-44r-10r

- 18-44r-15r

- 18-44r-20r

- 18-44r-25r

- 18-44r-30r

- 18-44r-35r

- 18-44r-40r

- 18-44r-45r

- 18-44r-50r

- 18-45r-10r

- 18-45r-15r

- 18-45r-20r

- 18-45r-25r

- 18-45r-30r

- 18-45r-35r

- 18-45r-40r

- 18-45r-45r

- 18-45r-50r

- 18-46r-10r

- 18-46r-15r

- 18-46r-20r

- 18-46r-25r

- 18-46r-30r

- 18-46r-35r

- 18-46r-40r

- 18-46r-45r

- 18-46r-50r

- 18-47r-10r

- 18-47r-15r

- 18-47r-20r

- 18-47r-25r

- 18-47r-30r

- 18-47r-35r

- 18-47r-40r

- 18-47r-45r

- 18-47r-50r

- 18-48r-10r

- 18-48r-15r

- 18-48r-20r

- 18-48r-25r

- 18-48r-30r

- 18-48r-35r

- 18-48r-40r

- 18-48r-45r

- 18-48r-50r

- 18-49r-10r

- 18-49r-15r

- 18-49r-20r

- 18-49r-25r

- 18-49r-30r

- 18-49r-35r

- 18-49r-40r

- 18-49r-45r

- 18-49r-50r

- 18-50r-10r

- 18-50r-15r

- 18-50r-20r

- 18-50r-25r

- 18-50r-30r

- 18-50r-35r

- 18-50r-40r

- 18-50r-45r

- 18-50r-50r

- 18-51r-10r

- 18-51r-15r

- 18-51r-20r

- 18-51r-25r

- 18-51r-30r

- 18-51r-35r

- 18-51r-40r

- 18-51r-45r

- 18-51r-50r

- 18-52r-10r

- 18-52r-15r

- 18-52r-20r

- 18-52r-25r

- 18-52r-30r

- 18-52r-35r

- 18-52r-40r

- 18-52r-45r

- 18-52r-50r

- 18-53r-10r

- 18-53r-15r

- 18-53r-20r

- 18-53r-25r

- 18-53r-30r

- 18-53r-35r

- 18-53r-40r

- 18-53r-45r

- 18-53r-50r

- 18-54r-10r

- 18-54r-15r

- 18-54r-20r

- 18-54r-25r

- 18-54r-30r

- 18-54r-35r

- 18-54r-40r

- 18-54r-45r

- 18-54r-50r

- 18-55r-10r

- 18-55r-15r

- 18-55r-20r

- 18-55r-25r

- 18-55r-30r

- 18-55r-35r

- 18-55r-40r

- 18-55r-45r

- 18-55r-50r

- 18-56r-10r

- 18-56r-15r

- 18-56r-20r

- 18-56r-25r

- 18-56r-30r

- 18-56r-35r

- 18-56r-40r

- 18-56r-45r

- 18-56r-50r

- 18-57r-10r

- 18-57r-15r

- 18-57r-20r

- 18-57r-25r

- 18-57r-30r

- 18-57r-35r

- 18-57r-40r

- 18-57r-45r

- 18-57r-50r

- 18-58r-10r

- 18-58r-15r

- 18-58r-20r

- 18-58r-25r

- 18-58r-30r

- 18-58r-35r

- 18-58r-40r

- 18-58r-45r

- 18-58r-50r

- 18-59r-10r

- 18-59r-15r

- 18-59r-20r

- 18-59r-25r

- 18-59r-30r

- 18-59r-35r

- 18-59r-40r

- 18-59r-45r

- 18-59r-50r

- 18-60r-10r

- 18-60r-15r

- 18-60r-20r

- 18-60r-25r

- 18-60r-30r

- 18-60r-35r

- 18-60r-40r

- 18-60r-45r

- 18-60r-50r

- 18-61r-10r

- 18-61r-15r

- 18-61r-20r

- 18-61r-25r

- 18-61r-30r

- 18-61r-35r

- 18-61r-40r

- 18-61r-45r

- 18-61r-50r

- 18-62r-10r

- 18-62r-15r

- 18-62r-20r

- 18-62r-25r

- 18-62r-30r

- 18-62r-35r

- 18-62r-40r

- 18-62r-45r

- 18-62r-50r

- 18-63r-10r

- 18-63r-15r

- 18-63r-20r

- 18-63r-25r

- 18-63r-30r

- 18-63r-35r

- 18-63r-40r

- 18-63r-45r

- 18-63r-50r

- 18-64r-10r

- 18-64r-15r

- 18-64r-20r

- 18-64r-25r

- 18-64r-30r

- 18-64r-35r

- 18-64r-40r

- 18-64r-45r

- 18-64r-50r

- 18-65r-10r

- 18-65r-15r

- 18-65r-20r

- 18-65r-25r

- 18-65r-30r

- 18-65r-35r

- 18-65r-40r

- 18-65r-45r

- 18-65r-50r

- 18-66r-10r

- 18-66r-15r

- 18-66r-20r

- 18-66r-25r

- 18-66r-30r

- 18-66r-35r

- 18-66r-40r

- 18-66r-45r

- 18-66r-50r

- 18-67r-10r

- 18-67r-15r

- 18-67r-20r

- 18-67r-25r

- 18-67r-30r

- 18-67r-35r

- 18-67r-40r

- 18-67r-45r

- 18-67r-50r

- 18-68r-10r

- 18-68r-15r

- 18-68r-20r

- 18-68r-25r

- 18-68r-30r

- 18-68r-35r

- 18-68r-40r

- 18-68r-45r

- 18-68r-50r

- 18-69r-10r

- 18-69r-15r

- 18-69r-20r

- 18-69r-25r

- 18-69r-30r

- 18-69r-35r

- 18-69r-40r

- 18-69r-45r

- 18-69r-50r

- 18-70r-10r

- 18-70r-15r

- 18-70r-20r

- 18-70r-25r

- 18-70r-30r

- 18-70r-35r

- 18-70r-40r

- 18-70r-45r

- 18-70r-50r

- 18-71r-10r

- 18-71r-15r

- 18-71r-20r

- 18-71r-25r

- 18-71r-30r

- 18-71r-35r

- 18-71r-40r

- 18-71r-45r

- 18-71r-50r

- 18-72r-10r

- 18-72r-15r

- 18-72r-20r

- 18-72r-25r

- 18-72r-30r

- 18-72r-35r

- 18-72r-40r

- 18-72r-45r

- 18-72r-50r

- 18-73r-10r

- 18-73r-15r

- 18-73r-20r

- 18-73r-25r

- 18-73r-30r

- 18-73r-35r

- 18-73r-40r

- 18-73r-45r

- 18-73r-50r

- 18-74r-10r

- 18-74r-15r

- 18-74r-20r

- 18-74r-25r

- 18-74r-30r

- 18-74r-35r

- 18-74r-40r

- 18-74r-45r

- 18-74r-50r

- 18-75r-10r

- 18-75r-15r

- 18-75r-20r

- 18-75r-25r

- 18-75r-30r

- 18-75r-35r

- 18-75r-40r

- 18-75r-45r

- 18-75r-50r

- 18-76r-10r

- 18-76r-15r

- 18-76r-20r

- 18-76r-25r

- 18-76r-30r

- 18-76r-35r

- 18-76r-40r

- 18-76r-45r

- 18-76r-50r

- 18-77r-10r

- 18-77r-15r

- 18-77r-20r

- 18-77r-25r

- 18-77r-30r

- 18-77r-35r

- 18-77r-40r

- 18-77r-45r

- 18-77r-50r

- 18-78r-10r

- 18-78r-15r

- 18-78r-20r

- 18-78r-25r

- 18-78r-30r

- 18-78r-35r

- 18-78r-40r

- 18-78r-45r

- 18-78r-50r

- 18-79r-10r

- 18-79r-15r

- 18-79r-20r

- 18-79r-25r

- 18-79r-30r

- 18-79r-35r

- 18-79r-40r

- 18-79r-45r

- 18-79r-50r

- 18-80r-10r

- 18-80r-15r

- 18-80r-20r

- 18-80r-25r

- 18-80r-30r

- 18-80r-35r

- 18-80r-40r

- 18-80r-45r

- 18-80r-50r

- 18-81r-10r

- 18-81r-15r

- 18-81r-20r

- 18-81r-25r

- 18-81r-30r

- 18-81r-35r

- 18-81r-40r

- 18-81r-45r

- 18-81r-50r

- 18-82r-10r

- 18-82r-15r

- 18-82r-20r

- 18-82r-25r

- 18-82r-30r

- 18-82r-35r

- 18-82r-40r

- 18-82r-45r

- 18-82r-50r

- 18-83r-10r

- 18-83r-15r

- 18-83r-20r

- 18-83r-25r

- 18-83r-30r

- 18-83r-35r

- 18-83r-40r

- 18-83r-45r

- 18-83r-50r

- 18-84r-10r

- 18-84r-15r

- 18-84r-20r

- 18-84r-25r

- 18-84r-30r

- 18-84r-35r

- 18-84r-40r

- 18-84r-45r

- 18-84r-50r

- 18-85r-10r

- 18-85r-15r

- 18-85r-20r

- 18-85r-25r

- 18-85r-30r

- 18-85r-35r

- 18-85r-40r

- 18-85r-45r

- 18-85r-50r

- 18-86r-10r

- 18-86r-15r

- 18-86r-20r

- 18-86r-25r

- 18-86r-30r

- 18-86r-35r

- 18-86r-40r

- 18-86r-45r

- 18-86r-50r

- 18-87r-10r

- 18-87r-15r

- 18-87r-20r

- 18-87r-25r

- 18-87r-30r

- 18-87r-35r

- 18-87r-40r

- 18-87r-45r

- 18-87r-50r

- 18-88r-10r

- 18-88r-15r

- 18-88r-20r

- 18-88r-25r

- 18-88r-30r

- 18-88r-35r

- 18-88r-40r

- 18-88r-45r

- 18-88r-50r

- 18-89r-10r

- 18-89r-15r

- 18-89r-20r

- 18-89r-25r

- 18-89r-30r

- 18-89r-35r

- 18-89r-40r

- 18-89r-45r

- 18-89r-50r

- 18-90r-10r

- 18-90r-15r

- 18-90r-20r

- 18-90r-25r

- 18-90r-30r

- 18-90r-35r

- 18-90r-40r

- 18-90r-45r

- 18-90r-50r

- 18-91r-10r

- 18-91r-15r

- 18-91r-20r

- 18-91r-25r

- 18-91r-30r

- 18-91r-35r

- 18-91r-40r

- 18-91r-45r

- 18-91r-50r

- 18-92r-10r

- 18-92r-15r

- 18-92r-20r

- 18-92r-25r

- 18-92r-30r

- 18-92r-35r

- 18-92r-40r

- 18-92r-45r

- 18-92r-50r

- 18-93r-10r

- 18-93r-15r

- 18-93r-20r

- 18-93r-25r

- 18-93r-30r

- 18-93r-35r

- 18-93r-40r

- 18-93r-45r

- 18-93r-50r

- 18-94r-10r

- 18-94r-15r

- 18-94r-20r

- 18-94r-25r

- 18-94r-30r

- 18-94r-35r

- 18-94r-40r

- 18-94r-45r

- 18-94r-50r

- 18-95r-10r

- 18-95r-15r

- 18-95r-20r

- 18-95r-25r

- 18-95r-30r

- 18-95r-35r

- 18-95r-40r

- 18-95r-45r

- 18-95r-50r

- 18-96r-10r

- 18-96r-15r

- 18-96r-20r

- 18-96r-25r

- 18-96r-30r

- 18-96r-35r

- 18-96r-40r

- 18-96r-45r

- 18-96r-50r

- 18-97r-10r

- 18-97r-15r

- 18-97r-20r

- 18-97r-25r

- 18-97r-30r

- 18-97r-35r

- 18-97r-40r

- 18-97r-45r

- 18-97r-50r

- 18-98r-10r

- 18-98r-15r

- 18-98r-20r

- 18-98r-25r

- 18-98r-30r

- 18-98r-35r

- 18-98r-40r

- 18-98r-45r

- 18-98r-50r

- 18-99r-10r

- 18-99r-15r

- 18-99r-20r

- 18-99r-25r

- 18-99r-30r

- 18-99r-35r

- 18-99r-40r

- 18-99r-45r

- 18-99r-50r

- 18-100r-10r

- 18-100r-15r

- 18-100r-20r

- 18-100r-25r

- 18-100r-30r

- 18-100r-35r

- 18-100r-40r

- 18-100r-45r

- 18-100r-50r

- 18-22y-10y

- 18-22y-15y

- 18-22y-20y

- 18-22y-25y

- 18-22y-30y

- 18-22y-35y

- 18-22y-40y

- 18-22y-45y

- 18-22y-50y

- 18-23y-10y

- 18-23y-15y

- 18-23y-20y

- 18-23y-25y

- 18-23y-30y

- 18-23y-35y

- 18-23y-40y

- 18-23y-45y

- 18-23y-50y

- 18-24y-10y

- 18-24y-15y

- 18-24y-20y

- 18-24y-25y

- 18-24y-30y

- 18-24y-35y

- 18-24y-40y

- 18-24y-45y

- 18-24y-50y

- 18-25y-10y

- 18-25y-15y

- 18-25y-20y

- 18-25y-25y

- 18-25y-30y

- 18-25y-35y

- 18-25y-40y

- 18-25y-45y

- 18-25y-50y

- 18-26y-10y

- 18-26y-15y

- 18-26y-20y

- 18-26y-25y

- 18-26y-30y

- 18-26y-35y

- 18-26y-40y

- 18-26y-45y

- 18-26y-50y

- 18-27y-10y

- 18-27y-15y

- 18-27y-20y

- 18-27y-25y

- 18-27y-30y

- 18-27y-35y

- 18-27y-40y

- 18-27y-45y

- 18-27y-50y

- 18-28y-10y

- 18-28y-15y

- 18-28y-20y

- 18-28y-25y

- 18-28y-30y

- 18-28y-35y

- 18-28y-40y

- 18-28y-45y

- 18-28y-50y

- 18-29y-10y

- 18-29y-15y

- 18-29y-20y

- 18-29y-25y

- 18-29y-30y

- 18-29y-35y

- 18-29y-40y

- 18-29y-45y

- 18-29y-50y

- 18-30y-10y

- 18-30y-15y

- 18-30y-20y

- 18-30y-25y

- 18-30y-30y

- 18-30y-35y

- 18-30y-40y

- 18-30y-45y

- 18-30y-50y

- 18-31y-10y

- 18-31y-15y

- 18-31y-20y

- 18-31y-25y

- 18-31y-30y

- 18-31y-35y

- 18-31y-40y

- 18-31y-45y

- 18-31y-50y

- 18-32y-10y

- 18-32y-15y

- 18-32y-20y

- 18-32y-25y

- 18-32y-30y

- 18-32y-35y

- 18-32y-40y

- 18-32y-45y

- 18-32y-50y

- 18-33y-10y

- 18-33y-15y

- 18-33y-20y

- 18-33y-25y

- 18-33y-30y

- 18-33y-35y

- 18-33y-40y

- 18-33y-45y

- 18-33y-50y

- 18-34y-10y

- 18-34y-15y

- 18-34y-20y

- 18-34y-25y

- 18-34y-30y

- 18-34y-35y

- 18-34y-40y

- 18-34y-45y

- 18-34y-50y

- 18-35y-10y

- 18-35y-15y

- 18-35y-20y

- 18-35y-25y

- 18-35y-30y

- 18-35y-35y

- 18-35y-40y

- 18-35y-45y

- 18-35y-50y

- 18-36y-10y

- 18-36y-15y

- 18-36y-20y

- 18-36y-25y

- 18-36y-30y

- 18-36y-35y

- 18-36y-40y

- 18-36y-45y

- 18-36y-50y

- 18-37y-10y

- 18-37y-15y

- 18-37y-20y

- 18-37y-25y

- 18-37y-30y

- 18-37y-35y

- 18-37y-40y

- 18-37y-45y

- 18-37y-50y

- 18-38y-10y

- 18-38y-15y

- 18-38y-20y

- 18-38y-25y

- 18-38y-30y

- 18-38y-35y

- 18-38y-40y

- 18-38y-45y

- 18-38y-50y

- 18-39y-10y

- 18-39y-15y

- 18-39y-20y

- 18-39y-25y

- 18-39y-30y

- 18-39y-35y

- 18-39y-40y

- 18-39y-45y

- 18-39y-50y

- 18-40y-10y

- 18-40y-15y

- 18-40y-20y

- 18-40y-25y

- 18-40y-30y

- 18-40y-35y

- 18-40y-40y

- 18-40y-45y

- 18-40y-50y

- 18-41y-10y

- 18-41y-15y

- 18-41y-20y

- 18-41y-25y

- 18-41y-30y

- 18-41y-35y

- 18-41y-40y

- 18-41y-45y

- 18-41y-50y

- 18-42y-10y

- 18-42y-15y

- 18-42y-20y

- 18-42y-25y

- 18-42y-30y

- 18-42y-35y

- 18-42y-40y

- 18-42y-45y

- 18-42y-50y

- 18-43y-10y

- 18-43y-15y

- 18-43y-20y

- 18-43y-25y

- 18-43y-30y

- 18-43y-35y

- 18-43y-40y

- 18-43y-45y

- 18-43y-50y

- 18-44y-10y

- 18-44y-15y

- 18-44y-20y

- 18-44y-25y

- 18-44y-30y

- 18-44y-35y

- 18-44y-40y

- 18-44y-45y

- 18-44y-50y

- 18-45y-10y

- 18-45y-15y

- 18-45y-20y

- 18-45y-25y

- 18-45y-30y

- 18-45y-35y

- 18-45y-40y

- 18-45y-45y

- 18-45y-50y

- 18-46y-10y

- 18-46y-15y

- 18-46y-20y

- 18-46y-25y

- 18-46y-30y

- 18-46y-35y

- 18-46y-40y

- 18-46y-45y

- 18-46y-50y

- 18-47y-10y

- 18-47y-15y

- 18-47y-20y

- 18-47y-25y

- 18-47y-30y

- 18-47y-35y

- 18-47y-40y

- 18-47y-45y

- 18-47y-50y

- 18-48y-10y

- 18-48y-15y

- 18-48y-20y

- 18-48y-25y

- 18-48y-30y

- 18-48y-35y

- 18-48y-40y

- 18-48y-45y

- 18-48y-50y

- 18-49y-10y

- 18-49y-15y

- 18-49y-20y

- 18-49y-25y

- 18-49y-30y

- 18-49y-35y

- 18-49y-40y

- 18-49y-45y

- 18-49y-50y

- 18-50y-10y

- 18-50y-15y

- 18-50y-20y

- 18-50y-25y

- 18-50y-30y

- 18-50y-35y

- 18-50y-40y

- 18-50y-45y

- 18-50y-50y

- 18-51y-10y

- 18-51y-15y

- 18-51y-20y

- 18-51y-25y

- 18-51y-30y

- 18-51y-35y

- 18-51y-40y

- 18-51y-45y

- 18-51y-50y

- 18-52y-10y

- 18-52y-15y

- 18-52y-20y

- 18-52y-25y

- 18-52y-30y

- 18-52y-35y

- 18-52y-40y

- 18-52y-45y

- 18-52y-50y

- 18-53y-10y

- 18-53y-15y

- 18-53y-20y

- 18-53y-25y

- 18-53y-30y

- 18-53y-35y

- 18-53y-40y

- 18-53y-45y

- 18-53y-50y

- 18-54y-10y

- 18-54y-15y

- 18-54y-20y

- 18-54y-25y

- 18-54y-30y

- 18-54y-35y

- 18-54y-40y

- 18-54y-45y

- 18-54y-50y

- 18-55y-10y

- 18-55y-15y

- 18-55y-20y

- 18-55y-25y

- 18-55y-30y

- 18-55y-35y

- 18-55y-40y

- 18-55y-45y

- 18-55y-50y

- 18-56y-10y

- 18-56y-15y

- 18-56y-20y

- 18-56y-25y

- 18-56y-30y

- 18-56y-35y

- 18-56y-40y

- 18-56y-45y

- 18-56y-50y

- 18-57y-10y

- 18-57y-15y

- 18-57y-20y

- 18-57y-25y

- 18-57y-30y

- 18-57y-35y

- 18-57y-40y

- 18-57y-45y

- 18-57y-50y

- 18-58y-10y

- 18-58y-15y

- 18-58y-20y

- 18-58y-25y

- 18-58y-30y

- 18-58y-35y

- 18-58y-40y

- 18-58y-45y

- 18-58y-50y

- 18-59y-10y

- 18-59y-15y

- 18-59y-20y

- 18-59y-25y

- 18-59y-30y

- 18-59y-35y

- 18-59y-40y

- 18-59y-45y

- 18-59y-50y

- 18-60y-10y

- 18-60y-15y

- 18-60y-20y

- 18-60y-25y

- 18-60y-30y

- 18-60y-35y

- 18-60y-40y

- 18-60y-45y

- 18-60y-50y

- 18-61y-10y

- 18-61y-15y

- 18-61y-20y

- 18-61y-25y

- 18-61y-30y

- 18-61y-35y

- 18-61y-40y

- 18-61y-45y

- 18-61y-50y

- 18-62y-10y

- 18-62y-15y

- 18-62y-20y

- 18-62y-25y

- 18-62y-30y

- 18-62y-35y

- 18-62y-40y

- 18-62y-45y

- 18-62y-50y

- 18-63y-10y

- 18-63y-15y

- 18-63y-20y

- 18-63y-25y

- 18-63y-30y

- 18-63y-35y

- 18-63y-40y

- 18-63y-45y

- 18-63y-50y

- 18-64y-10y

- 18-64y-15y

- 18-64y-20y

- 18-64y-25y

- 18-64y-30y

- 18-64y-35y

- 18-64y-40y

- 18-64y-45y

- 18-64y-50y

- 18-65y-10y

- 18-65y-15y

- 18-65y-20y

- 18-65y-25y

- 18-65y-30y

- 18-65y-35y

- 18-65y-40y

- 18-65y-45y

- 18-65y-50y

- 18-66y-10y

- 18-66y-15y

- 18-66y-20y

- 18-66y-25y

- 18-66y-30y

- 18-66y-35y

- 18-66y-40y

- 18-66y-45y

- 18-66y-50y

- 18-67y-10y

- 18-67y-15y

- 18-67y-20y

- 18-67y-25y

- 18-67y-30y

- 18-67y-35y

- 18-67y-40y

- 18-67y-45y

- 18-67y-50y

- 18-68y-10y

- 18-68y-15y

- 18-68y-20y

- 18-68y-25y

- 18-68y-30y

- 18-68y-35y

- 18-68y-40y

- 18-68y-45y

- 18-68y-50y

- 18-69y-10y

- 18-69y-15y

- 18-69y-20y

- 18-69y-25y

- 18-69y-30y

- 18-69y-35y

- 18-69y-40y

- 18-69y-45y

- 18-69y-50y

- 18-70y-10y

- 18-70y-15y

- 18-70y-20y

- 18-70y-25y

- 18-70y-30y

- 18-70y-35y

- 18-70y-40y

- 18-70y-45y

- 18-70y-50y

- 18-71y-10y

- 18-71y-15y

- 18-71y-20y

- 18-71y-25y

- 18-71y-30y

- 18-71y-35y

- 18-71y-40y

- 18-71y-45y

- 18-71y-50y

- 18-72y-10y

- 18-72y-15y

- 18-72y-20y

- 18-72y-25y

- 18-72y-30y

- 18-72y-35y