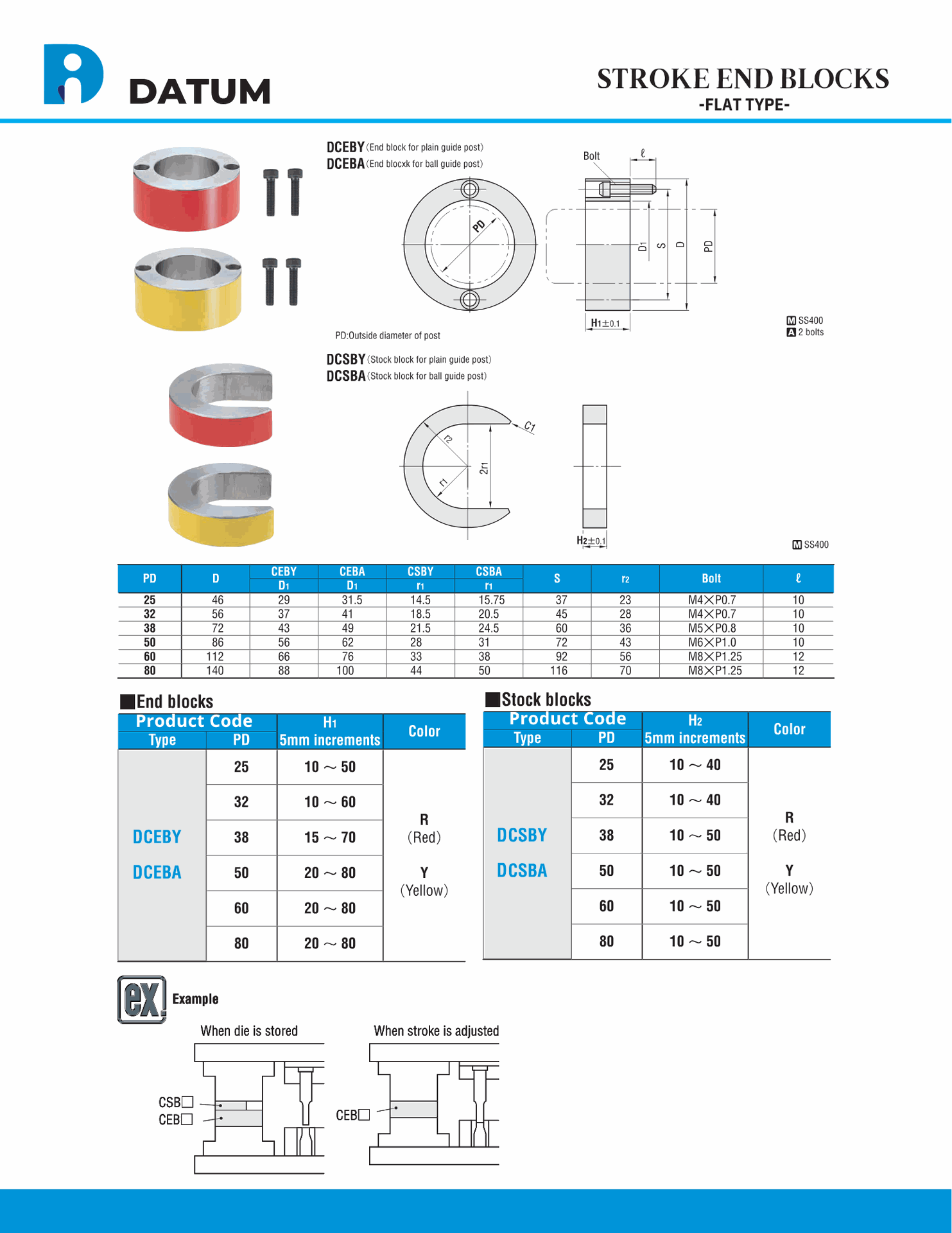

STROKE END BLOCKS

Flat Type

Stroke end blocks (flat type) are essential components in maintaining precise die positioning and alignment during press operations. These blocks are designed to withstand high pressure, ensuring consistent and reliable performance in die sets. Made from durable materials, flat type stroke end blocks help stabilize the die set and prevent unwanted movement, improving production efficiency and reducing downtime. Ideal for industries that require high precision, these stroke end blocks are a key factor in achieving optimal results in press operations.

Stroke end blocks (flat type) are critical components in maintaining the precise positioning and stability of die sets during press operations. These blocks are designed to secure the die in place, preventing any unwanted movement that could lead to misalignment or faulty parts. Ideal for heavy-duty presses, flat-type stroke end blocks provide essential support for consistent, high-quality production.

Crafted from high-quality materials, these stroke end blocks are built to withstand the pressures and forces exerted during stamping, punching, or pressing operations. The flat design ensures optimal die alignment and minimizes wear and tear, extending the service life of both the die and press machine. This contributes to lower maintenance costs and improved operational efficiency.

In industries such as automotive, aerospace, and manufacturing, stroke end blocks help maintain consistent die performance by preventing the die from shifting or dislodging. The result is reduced downtime, fewer defects, and smoother production processes.

When you choose stroke end blocks, you are investing in a solution that enhances the longevity of your press system and boosts overall performance. With precise alignment and exceptional durability, flat-type stroke end blocks ensure that your press operations remain efficient, effective, and reliable.