Stroke End Blocks (Harden & Tapped)-DSBVM

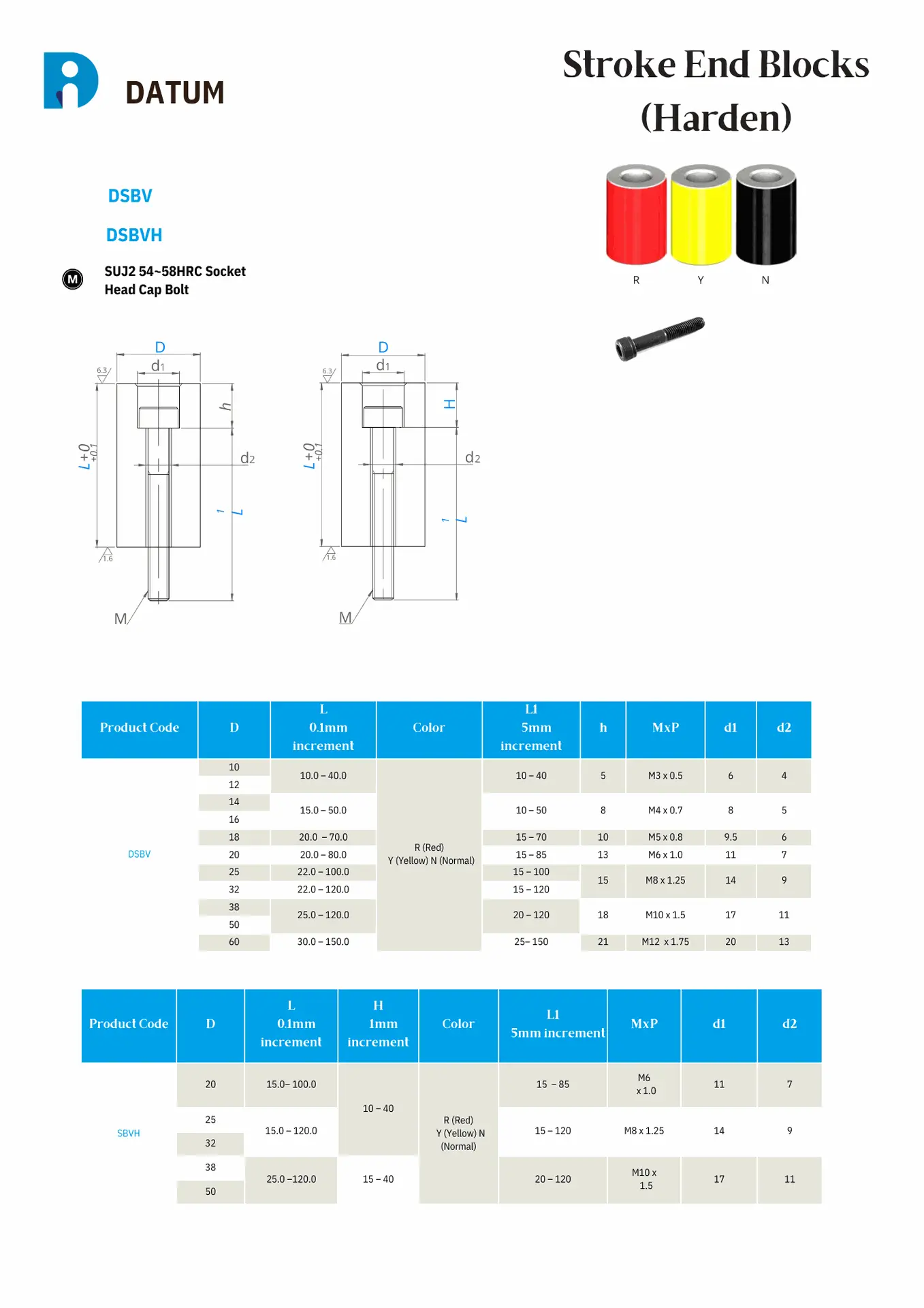

The Stroke End Blocks (Harden & Tapped) - DSBVM are high-performance components designed to maintain precise positioning and alignment in press-in die systems. Made from hardened, wear-resistant materials, these end blocks provide superior durability and stability during press operations. The tapped feature allows for easy installation and secure attachment, enhancing the efficiency of the press system. DSBVM Stroke End Blocks reduce misalignment, minimize wear, and extend die life, ensuring consistent, high-quality press performance. Ideal for industrial applications, these blocks help optimize operations and reduce maintenance costs in demanding environments.

The Stroke End Blocks (Harden & Tapped) - DSBVM are precision-engineered components specifically designed to maintain accurate positioning and alignment in press-in die systems. These high-performance end blocks are crafted from hardened, wear-resistant materials, ensuring exceptional durability and long-lasting performance even under the most demanding conditions. The tapped feature of the DSBVM Stroke End Blocks allows for easy installation and secure attachment, streamlining maintenance and improving the overall efficiency of the press system.

In press-in die systems, precise alignment of die components is crucial for minimizing misalignment, which can lead to defects, downtime, and increased wear. The DSBVM Stroke End Blocks help mitigate these risks by providing stable, secure positioning that keeps the die components aligned throughout the press cycle. This ensures smoother operations, reduces the potential for defects, and improves the consistency of the final product.

The hardened construction of these end blocks provides outstanding resistance to wear and tear, significantly extending the lifespan of both the die system and its components. This durability results in fewer replacements and less frequent maintenance, offering a cost-effective solution for manufacturers. Additionally, the DSBVM Stroke End Blocks help reduce operational downtime, enabling more efficient press cycles and higher overall productivity.

By incorporating the Stroke End Blocks (Harden & Tapped) - DSBVM into press systems, manufacturers can ensure precise die alignment, reducing production errors and enhancing overall press performance. These end blocks are ideal for high-demand industrial applications, offering a reliable, long-term solution to maintaining optimal press efficiency, minimizing maintenance costs, and improving operational output. Whether in heavy-duty or high-precision manufacturing environments, DSBVM Stroke End Blocks provide the stability and durability needed to maintain consistent, high-quality press performance.