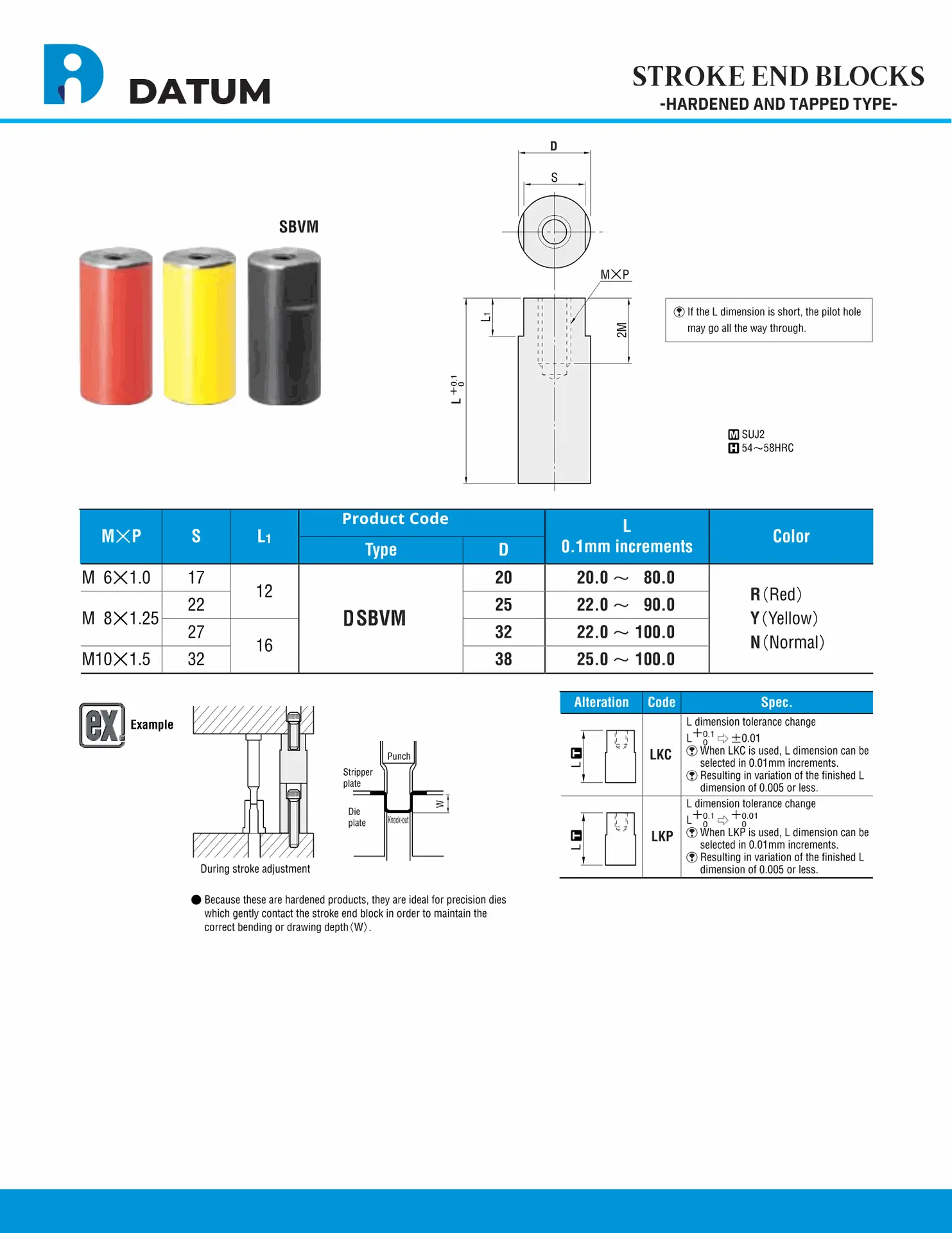

STROKE END BLOCKS

Hardened And Tapped Type

Hardened and tapped stroke end blocks are designed to offer superior strength and durability in press-in-die operations. With their hardened surface, these blocks provide excellent wear resistance, ensuring long-lasting performance under high-pressure conditions. The tapped feature allows for easy and secure attachment, improving the efficiency of die maintenance and positioning. Ideal for industries such as automotive, metalworking, and aerospace, these stroke end blocks ensure precision alignment and minimal downtime, making them a reliable solution for demanding press-in-die processes.

Stroke end blocks with hardened and tapped types are essential components for ensuring precise positioning and durability in press-in-die operations. Designed for heavy-duty use, these blocks are engineered with a hardened surface that offers exceptional wear resistance, making them ideal for high-pressure environments. The tapped design allows for easy installation and secure attachment, reducing maintenance time and improving the overall efficiency of die setups.

Manufactured to meet stringent quality standards, these hardened and tapped stroke end blocks are widely used across industries such as automotive, metalworking, aerospace, and manufacturing. Their ability to withstand continuous pressure and extreme conditions makes them a reliable choice for applications that demand precision and reliability. By maintaining the correct position of dies during the press-in-die process, these stroke end blocks help minimize errors and downtime, optimizing production workflows.

Whether you're working with stamping, punching, or molding operations, these blocks ensure that dies remain accurately positioned, thus enhancing the quality of the final product. Invest in hardened and tapped stroke end blocks for consistent performance, reduced wear, and increased efficiency in your press-in-die applications.