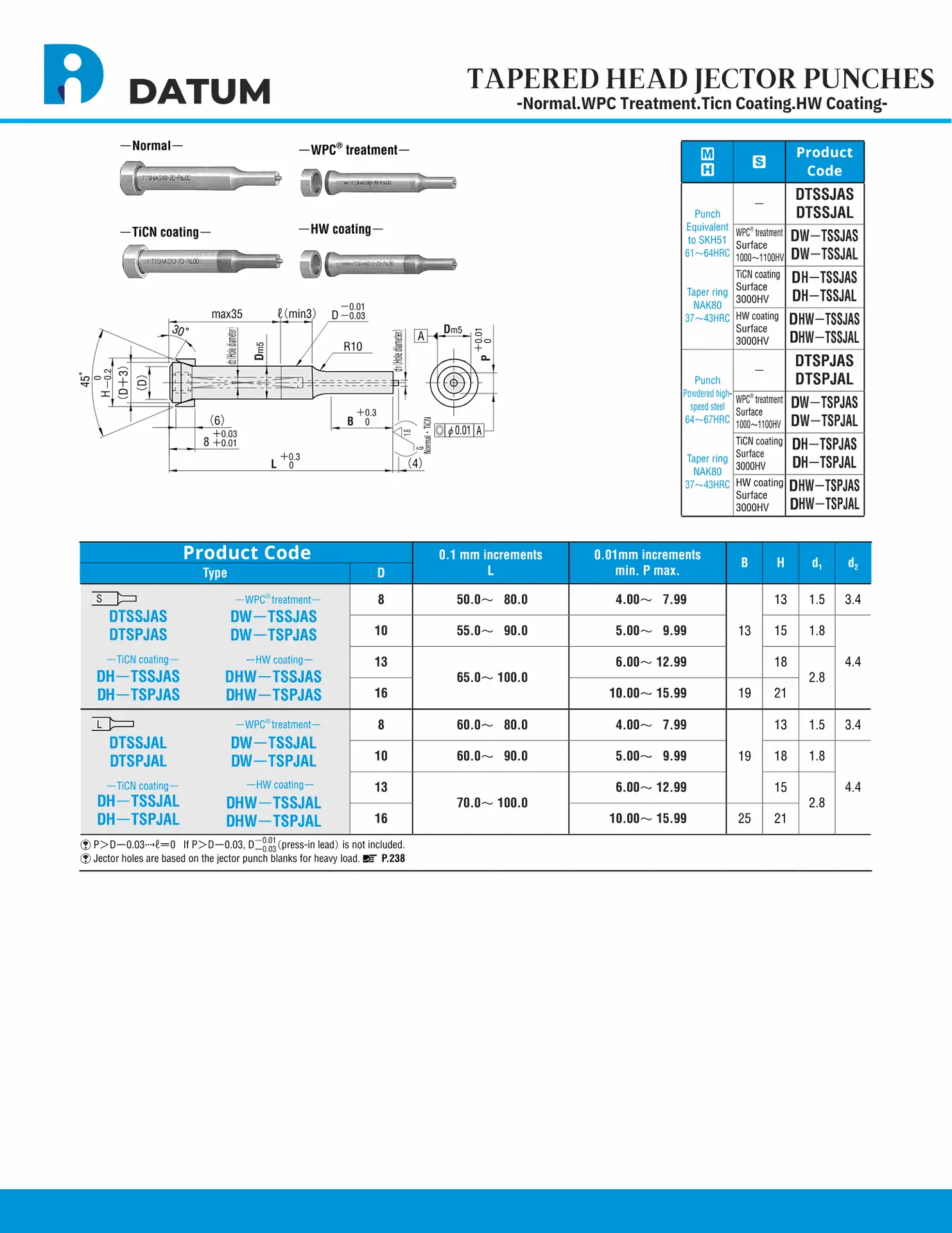

TAPERED HEAD JECTOR PUNCHES

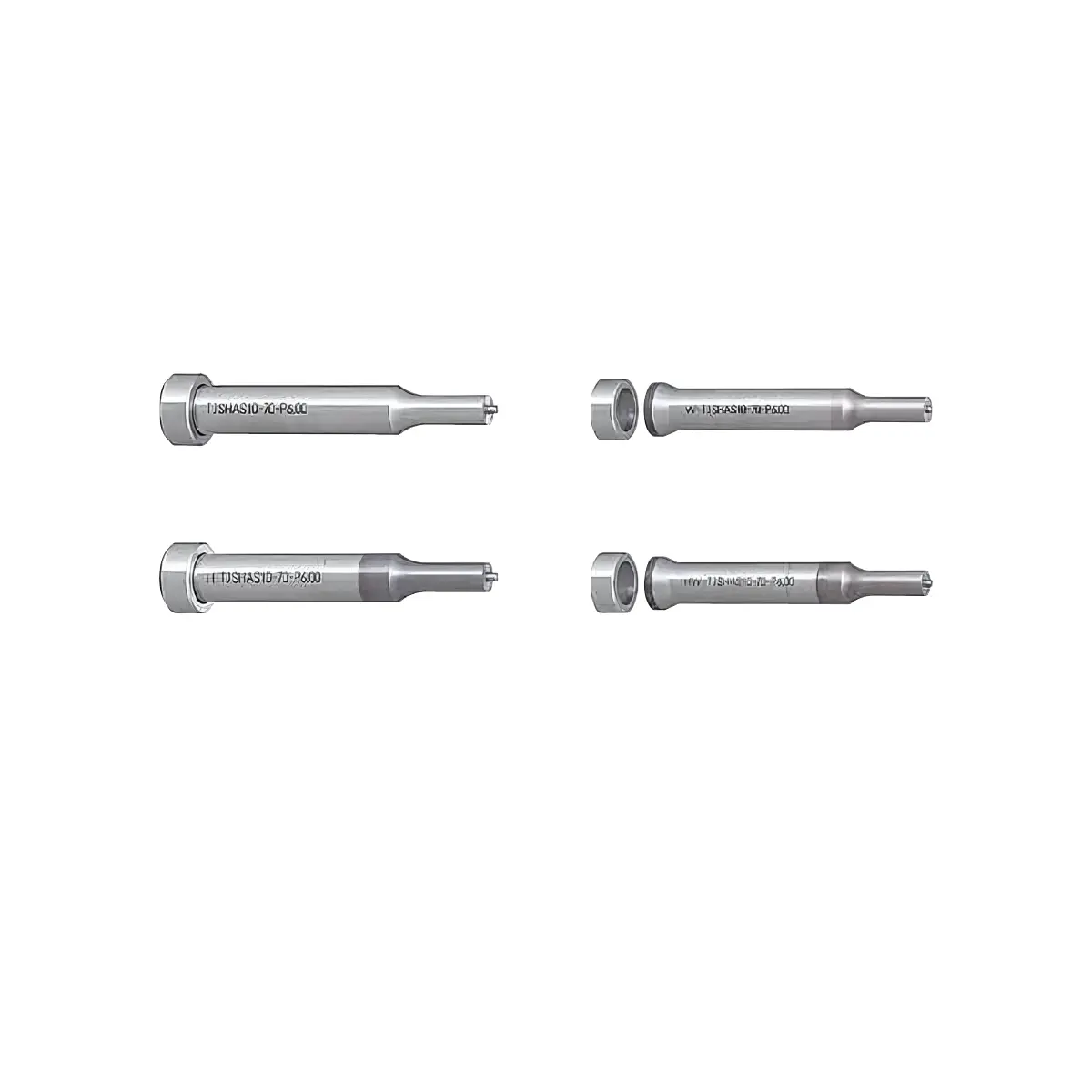

Normal WPC Treatment Ticn Coating HW Coating

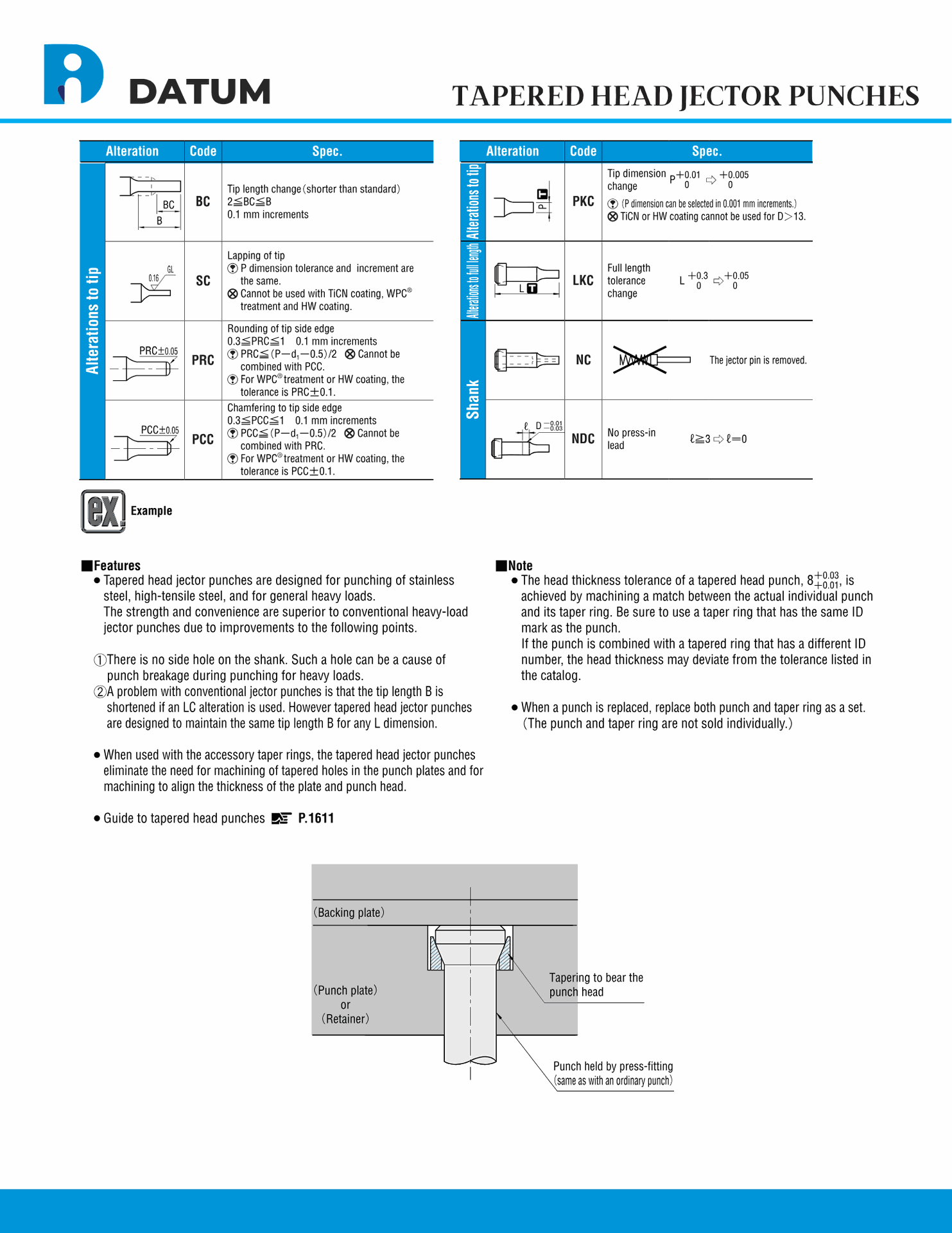

Tapered Head Jector Punches, featuring Normal WPC Treatment, TiCN Coating, and HW Coating, are designed for high-performance use in press-in-die applications. These punches provide excellent durability and wear resistance, ensuring reliable and consistent operation under heavy loads. The TiCN Coating enhances hardness, offering superior protection against abrasion, while the HW Coating provides additional resistance to heat and wear. Ideal for industries requiring precise and efficient punching, these Tapered Head Jector Punches are the optimal choice for maintaining position in demanding press-in-die environments.

Tapered Head Jector Punches with Normal WPC Treatment, TiCN Coating, and HW Coating are the ideal solution for maintaining position in press-in-die applications. These specialized punches are engineered to deliver maximum durability and reliability, even under the most demanding conditions. The Normal WPC treatment enhances the material's wear resistance, ensuring longevity and extended service life. TiCN Coating adds exceptional hardness to the punches, providing superior abrasion resistance and reducing wear over time. Additionally, the HW Coating offers protection against high temperatures, ensuring the punches perform efficiently in heat-intensive applications.

Designed for heavy-duty performance, these punches are perfect for industries requiring precise and efficient punching operations. Their tapered design allows for seamless insertion and accurate positioning, preventing slippage during use. Whether you're working with high-strength materials or intricate components, Tapered Head Jector Punches are crafted to meet the most rigorous standards of quality and performance.

Incorporating these advanced coatings and treatments ensures that the punches maintain optimal functionality, reducing downtime and maintenance costs. Choose Tapered Head Jector Punches with Normal WPC Treatment, TiCN Coating, and HW Coating for superior performance and reliability in press-in-die applications.