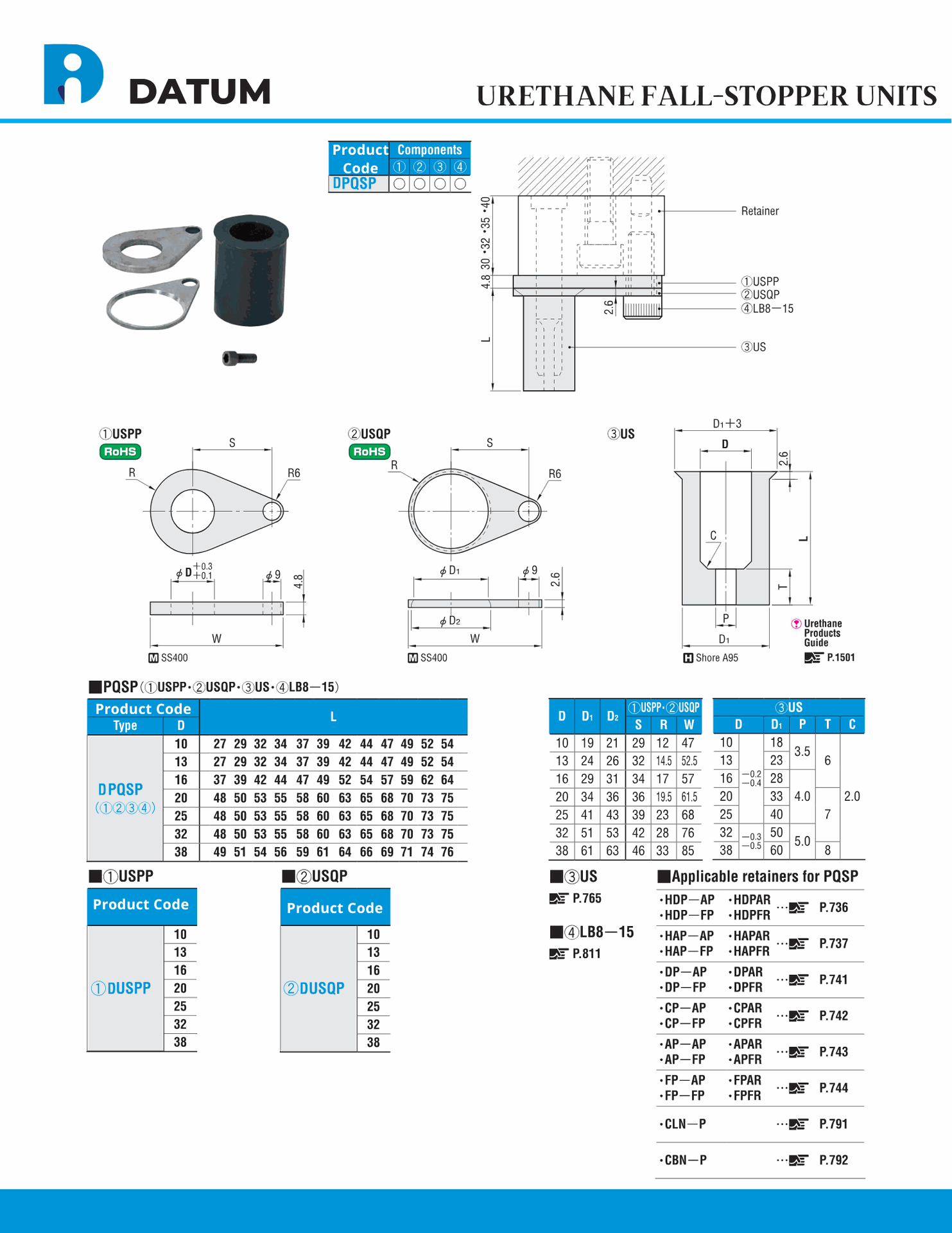

URETHANE FALL-STOPPER UNITS

Urethane fall-stopper units are crucial components in maintaining the position of the press in die systems. Designed for high durability, these units prevent parts from falling or shifting during the manufacturing process, ensuring accuracy and safety. Made from premium urethane, they offer excellent resistance to wear and tear, providing long-lasting performance. These fall-stopper units improve operational efficiency by minimizing errors and downtime, while enhancing product quality and maintaining the integrity of the press system.

Urethane fall-stopper units are essential for maintaining precision and stability in press-in-die systems. Engineered with high-grade urethane, these components ensure parts remain securely positioned during stamping, forming, or punching processes. Their robust construction resists wear, deformation, and impact, making them ideal for demanding industrial applications.

Designed to prevent workpieces from falling or shifting, urethane fall-stopper units enhance operational accuracy and safety. By reducing misalignment and minimizing downtime caused by part movement, these units significantly improve production efficiency. Their lightweight yet durable nature allows for easy installation and integration into various die setups without compromising performance.

Whether used in automotive, aerospace, or general manufacturing, urethane fall-stopper units deliver consistent results and extend the lifespan of press systems. They also help maintain die alignment, ensuring superior quality and precision in finished products. Available in customizable sizes and specifications, these units can be tailored to meet specific operational needs.

Investing in urethane fall-stopper units optimizes workflow, reduces material waste, and enhances overall productivity. Their exceptional performance and reliability make them a valuable addition to any press-in-die application, ensuring your operations run smoothly and efficiently.